Heating furnace hearth pressure and exhaust gas temperature control method and system and medium

A technology of exhaust gas temperature and control method, which is applied in the direction of control/regulation system, non-electric variable control, and simultaneous control of multiple variables. It can solve the problem that the control system cannot perform feedback adjustment, the control effect cannot be displayed immediately, and the furnace pressure control is stable. In order to achieve the effects of improved stability, small fluctuations in furnace pressure, and reduced fuel consumption per ton of steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be described in detail below with reference to the specific embodiments. The following examples will help to further understand the present invention in any form of technicians, but will not limit the invention in any form. It should be noted that several variations and improvements can be made without departing from the concept of the present invention without departing from the present invention. These are all of the scope of protection of the present invention.

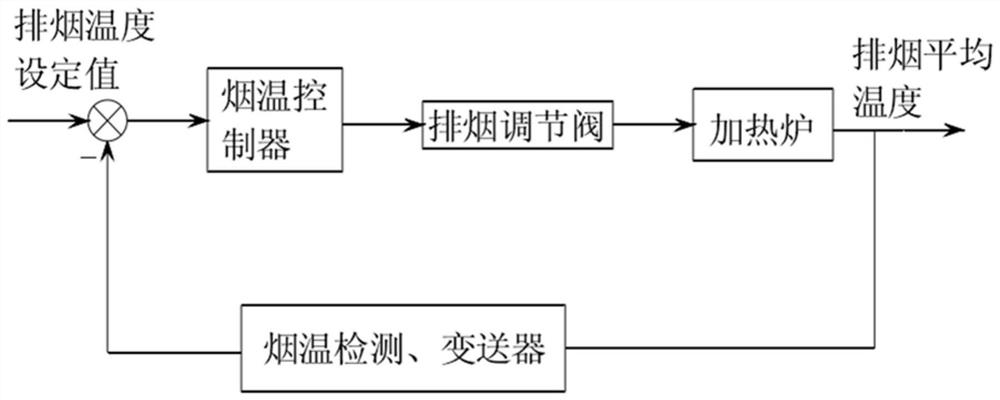

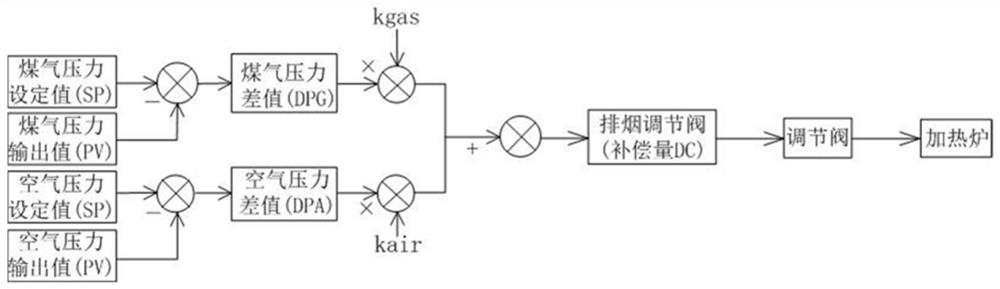

[0072] The present invention provides a method of heating furnace pressure and exhaust temperature control method based on a variable blurring interval. When the pressure in the heating furnace is too low, it will often cause cold air to enter the furnace in the furnace, which will cause a large amount of fuel. Waste; Conversely, if the furnace pressure is too high at this time, the hot air in the furnace will be discharged out of the furnace, which also leads to heat loss, resulting i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com