Start control method of air conditioner

An air conditioner and temperature adjustment technology, which is applied in heating and ventilation control systems, heating methods, high-efficiency adjustment technology, etc., can solve the problems of long compressor up-frequency and unfavorable user experience, etc., to reduce the amount of lubricating oil carried, improve User Experience, Effect of Solubility Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

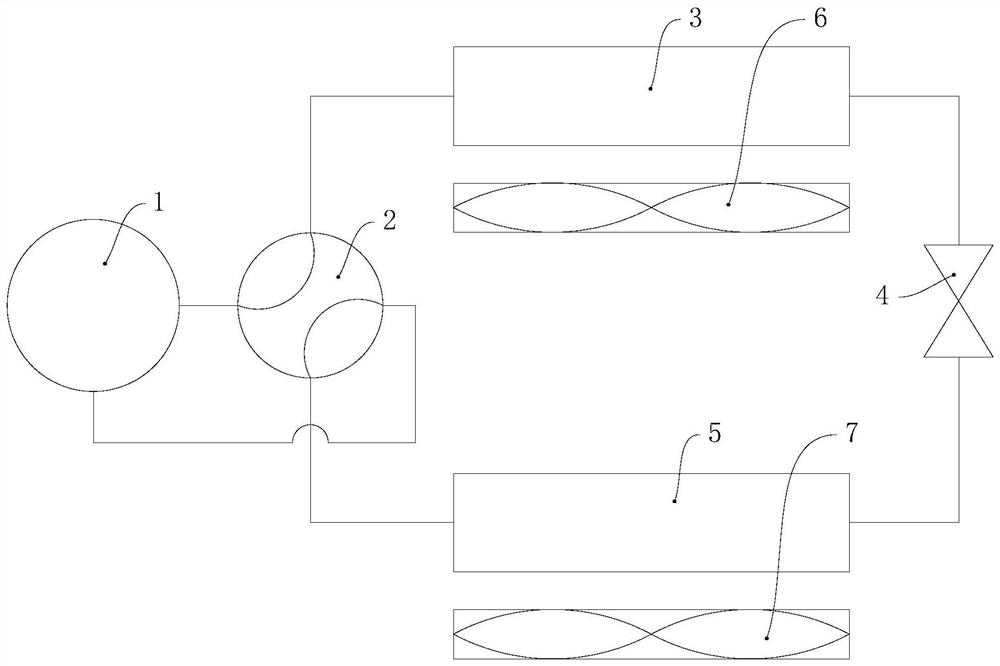

[0019] The air conditioner of this embodiment is a split type air conditioner of 1.5 hp, and the air conditioner includes a compressor 1, a reversing valve 2, an indoor heat exchanger 3, a throttle valve 4, an outdoor heat exchanger 5, an indoor fan 6 and an outdoor fan 7 , the operating modes of the air conditioner include cooling mode and heating mode. When the air conditioner is operating in the cooling mode, the indoor heat exchanger 3 is an evaporator, the indoor fan 6 is an evaporator fan, the outdoor heat exchanger 5 is a condenser, and the outdoor fan 7 is a condensing fan; similarly, when the air conditioner is running in heating mode, the outdoor heat exchanger 5 is an evaporator, the outdoor fan 7 is an evaporating fan, the indoor heat exchanger 3 is a condenser, and the indoor fan 6 is a condensing fan.

[0020] During the start-up process of the air conditioner (from start-up to normal temperature-adjustment operation), the operating frequency of compressor 1 needs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com