Two-dimensional thrust vectoring nozzle outer cover structure and design method thereof

A technology of vectoring nozzles and housings, which is applied to jet propulsion devices, machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

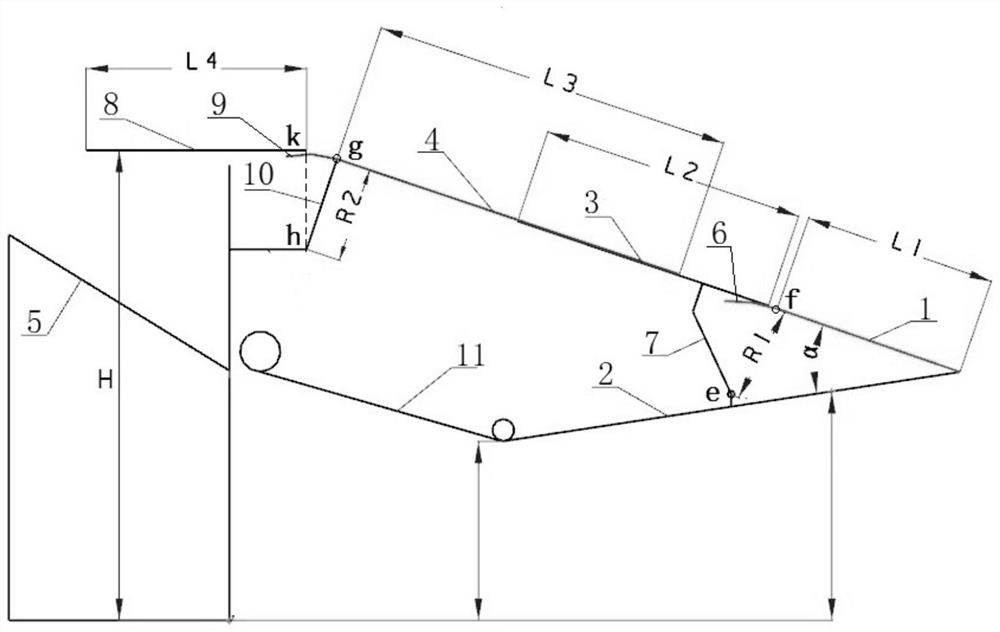

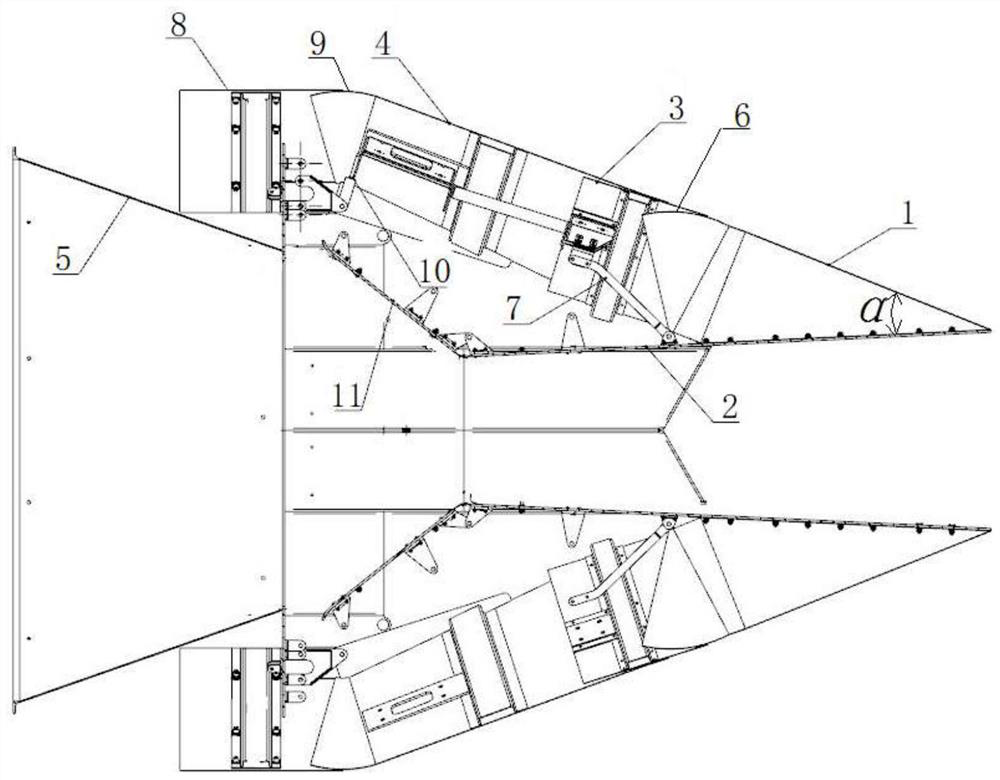

[0042] In order to make the technical solutions and advantages of the present application, the technical solutions of the present application will be further clarified, and the specific embodiments described herein will be appreciated that the specific embodiments described herein are only part of the present application. EXAMPLES, which is intended to explain the present application, not the limitation of the present application. It should be noted that in order to facilitate the description, only the portion related to the present application is shown, and other related portions can be referred to usual design, in the case of unlafred, the techniques in the present application and the embodiments Features can be combined with each other to obtain a new embodiment.

[0043] Moreover, unless otherwise defined, the technical terms or scientific terms used in this application description should be generally meanings that the art will appreciate the general artper of the present appl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com