Disc buckle frame

A disc button and disc technology, which is applied in the connection of scaffolding, building structure support, building structure support, etc., can solve problems such as the installation of horizontal bars and diagonal bars is not firm, cannot be installed, and horizontal bars and diagonal bars cannot be installed , to achieve the effect of facilitating on-site operation, eliminating angle errors and speeding up the erection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

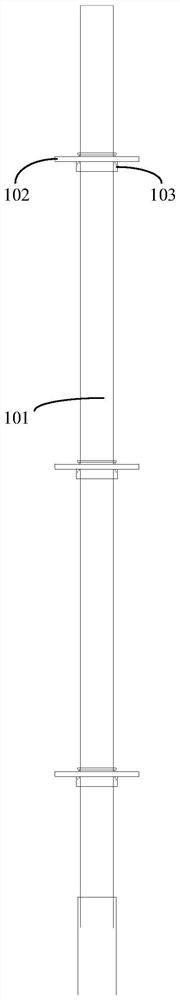

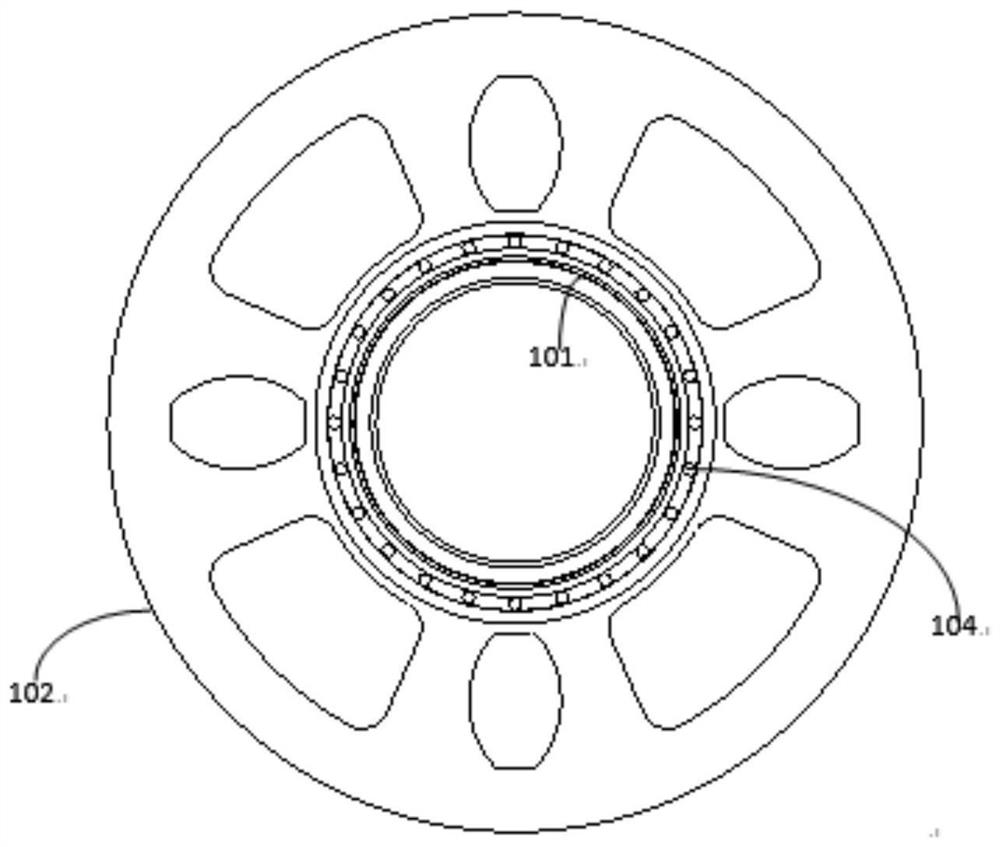

[0024] refer to figure 1 and figure 2 As shown, the present invention discloses a pan buckle rack, the pan buckle rack includes several vertical bars 101, horizontal bars and oblique bars, and each horizontal bar and inclined bar passes through the disc 102 arranged on the vertical bar 101 and the vertical bar 101 connected.

[0025] Preferably, the disc 102 is movably connected with the pole 101 .

[0026] Preferably, a bearing is provided between the disc 102 and the upright rod 101 . Preferably, several balls 104 are provided between the disc 102 and the upright 101 .

[0027] Therefore, by providing bearings or balls 104 between the disc 102 and the upright bar 101 , the rotatable position adjustment of the disc 102 relative to the upright bar 101 is realized.

[0028] Preferably, a support 103 is provided below the disc 102 , and the top of the support 103 is in contact with the bottom of the disc 102 .

[0029] Further, the supporting member 103 is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com