High-performance concrete cylindrical permanent formwork capable of being assembled and construction method thereof

A high-performance concrete, permanent technology, applied in the direction of erecting/assembling bridges, bridge parts, bridge materials, etc., can solve the problem of structural durability without targeted solutions, increase the uncertainty of structural bearing capacity, and the mechanics of permanent formwork members Uneven performance and other problems, to achieve the effect of easy control of construction quality, significant application value, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

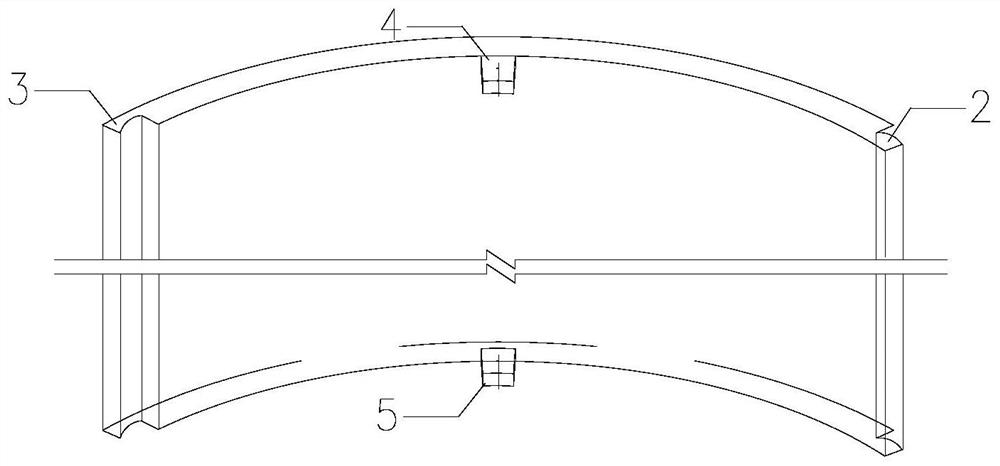

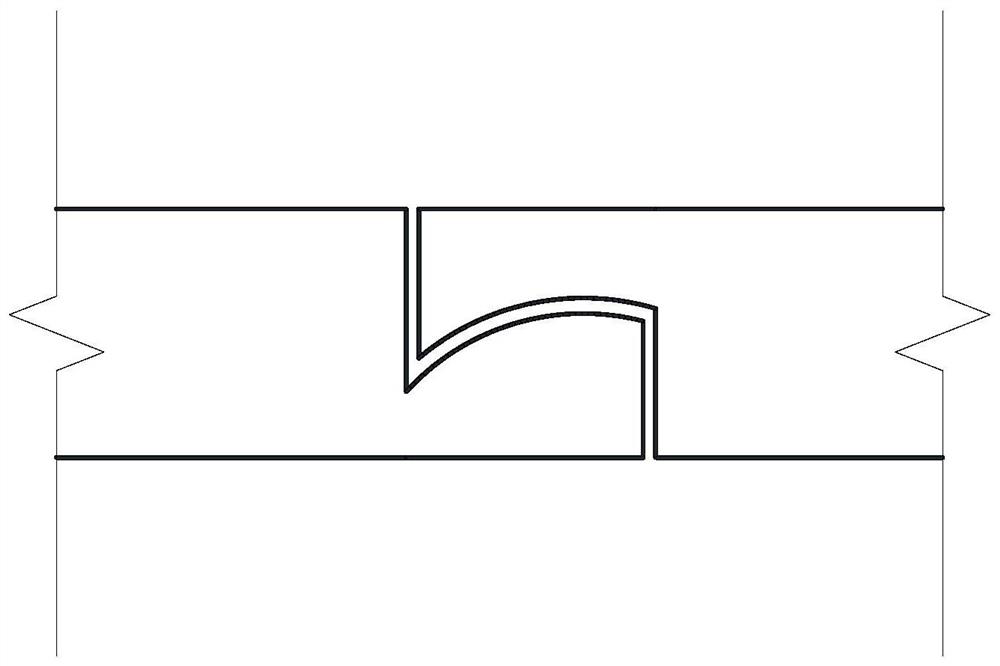

[0034] The structure of the ultra-high performance concrete assembled cylindrical permanent formwork described in this embodiment is as follows figure 1 As shown, a plurality of standard boards 1 are connected to each other through a vertical connection structure and a horizontal connection structure. The outer side of the standard board 1 is an arc surface, and the middle position of the top of the inner side of the standard board 1 is the first vertical connection. Structure 4, the middle position of the bottom of the inner side of the standard plate 1 is the second vertical connection structure 5, the first vertical connection structure 4 and the second vertical connection structure 5 are connected by bolts, and the horizontal connection structure is on the end surface of the standard plate 1 side The connection on the top is a mortise structure 2, and the connection on the other side of the standard plate 1 is a tenon structure 3, and the tenon structure 2 and the tenon str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com