Method for preparing calcium sulfate whiskers from phosphoric acid byproduct calcium chloride solution and sodium sulfate

A calcium chloride solution and calcium sulfate whisker technology are applied in chemical instruments and methods, solutions of liquid solvents at room temperature, single crystal growth, etc., and can solve the problems of high consumption of calcium sulfate whiskers raw materials and high energy consumption for preparation. Achieve the effect of reducing over-exploitation and consumption, high content, and increasing value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

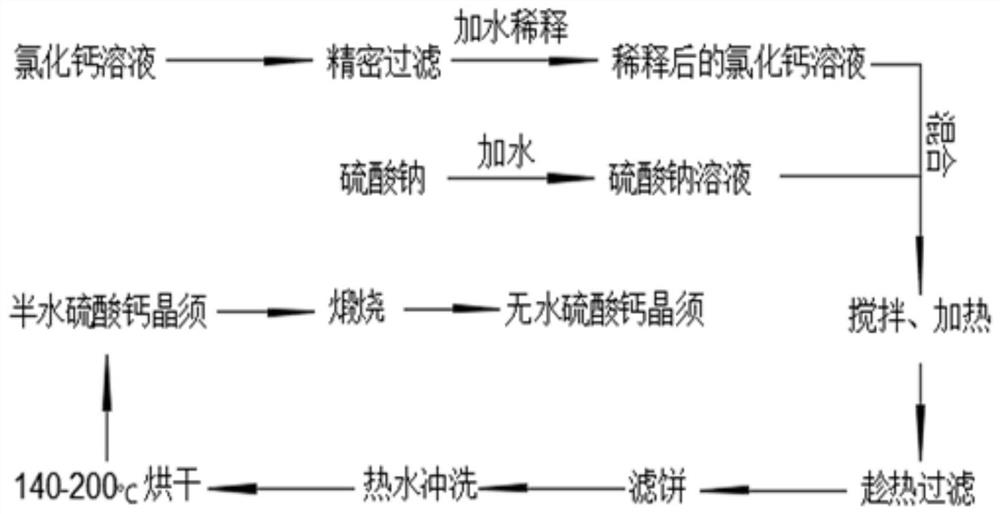

[0038] Such as figure 1 Shown, the phosphoric acid byproduct calcium chloride solution that the embodiment of the present invention provides and the method for preparing calcium sulfate whisker with sodium sulfate comprise the following steps:

[0039] (1) Add lime milk to the phosphoric acid by-product calcium chloride solution of the hydrochloric acid method wet method to adjust the solution to alkalinity, filter and extract the filtrate, add hydrochloric acid standard solution to the filtrate to adjust the pH value to 1; take 32ml of filtered hydrochloric acid method wet method Phosphoric acid by-product calcium chloride solution, add water to dilute to 500ml, obtain 20g / L calcium chloride solution;

[0040] (2) get 15g sodium sulfate, be configured into the sodium sulfate solution of 500ml, obtain the sodium sulfate solution of 30g / L;

[0041] (3) Mix the above two solutions, put them into the heat preservation reaction equipment, heat and stir to 120°C, and heat heat for...

Embodiment 2

[0045] Such as figure 1 Shown, the phosphoric acid byproduct calcium chloride solution that the embodiment of the present invention provides and the method for preparing calcium sulfate whisker with sodium sulfate comprise the following steps:

[0046] (1) Add lime milk to the phosphoric acid by-product calcium chloride solution of the hydrochloric acid method wet method to adjust the solution to alkalinity, filter and extract the filtrate, add hydrochloric acid standard solution to the filtrate to adjust the pH value to 1; take 128ml of filtered hydrochloric acid method wet method Phosphoric acid by-product calcium chloride solution, add water to dilute to 500ml, obtain 80g / L calcium chloride solution;

[0047] (2) get 60g sodium sulfate, be configured into the sodium sulfate solution of 500ml, obtain the sodium sulfate solution of 120g / L;

[0048] (3) Mix the above two solutions, put them into the heat preservation reaction equipment, heat and stir to 120°C, and heat heat f...

Embodiment 3

[0052] Such as figure 1 Shown, the phosphoric acid byproduct calcium chloride solution that the embodiment of the present invention provides and the method for preparing calcium sulfate whisker with sodium sulfate comprise the following steps:

[0053] (1) Add lime milk to the phosphoric acid by-product calcium chloride solution of the hydrochloric acid method wet method to adjust the solution to alkalinity, filter and extract the filtrate, add hydrochloric acid standard solution to the filtrate to adjust the pH value to 2; take 32ml of filtered hydrochloric acid method wet method Phosphoric acid by-product calcium chloride solution, add water to dilute to 500ml, obtain 20g / L calcium chloride solution;

[0054] (2) get 15g sodium sulfate, be configured into the sodium sulfate solution of 500ml, obtain the sodium sulfate solution of 30g / L;

[0055] (3) Mix the above two solutions, put them into the heat preservation reaction equipment, heat and stir to 110°C, and heat the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com