Balancing device for transmission shaft bracket of rolling mill

A technology of balancing device and transmission shaft, which is applied to the driving device of metal rolling mill, metal rolling, metal rolling, etc., which can solve the problem of undurable balancing device, and achieve easy maintenance, reduced swing, and no risk of breakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

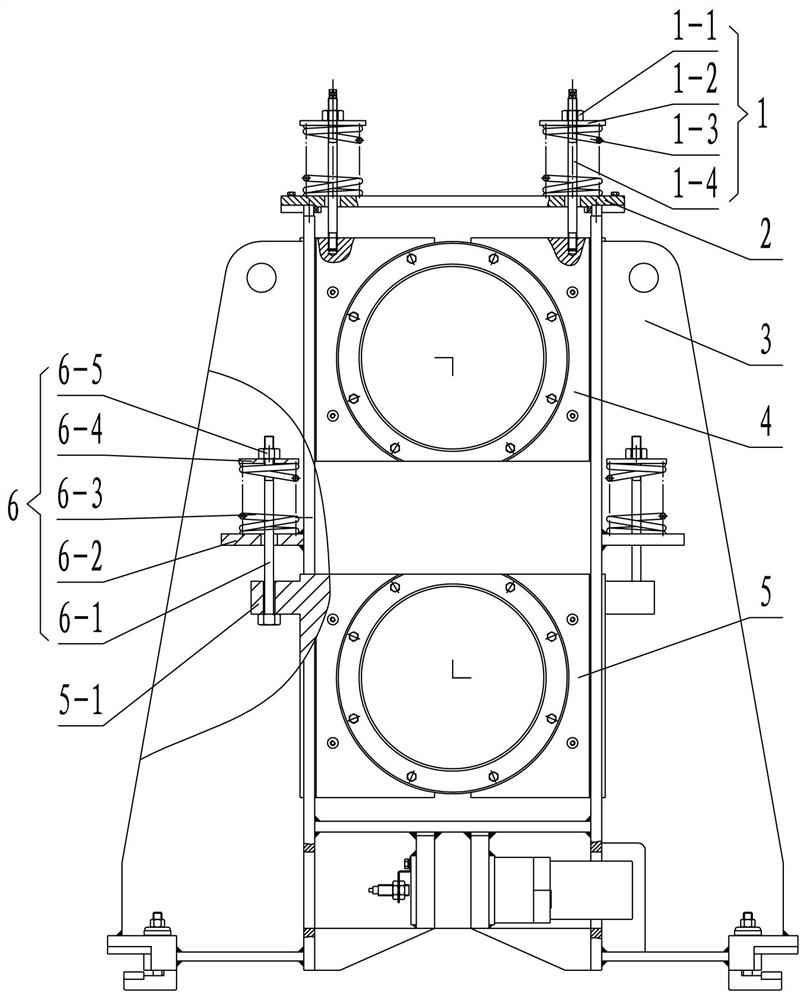

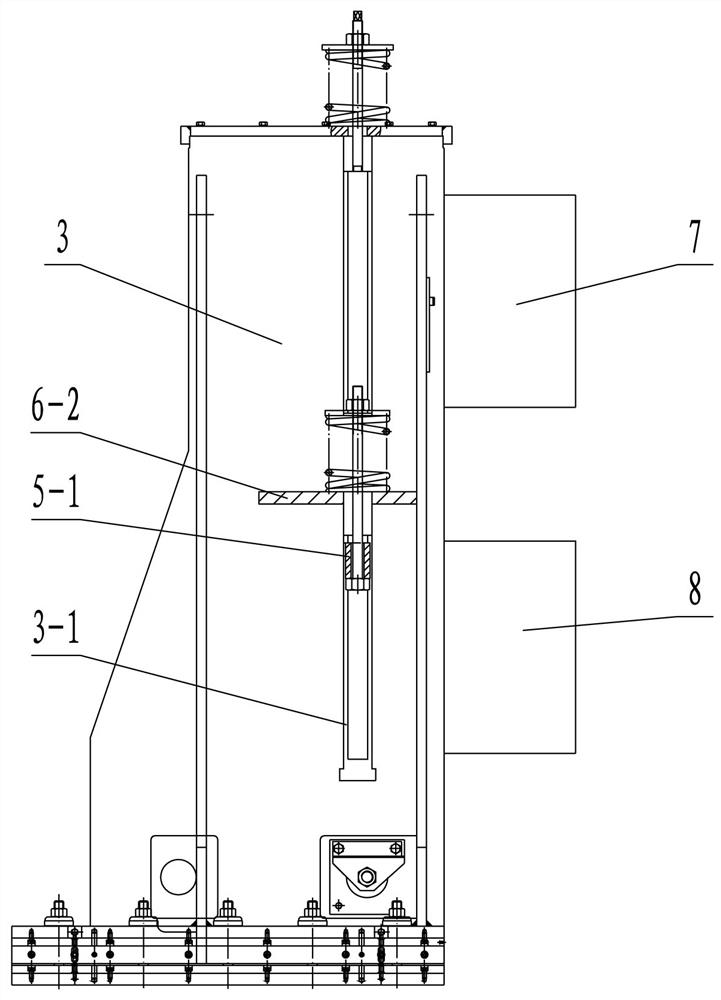

[0024] figure 1 and figure 2 The balance device of the drive shaft bracket of the rolling mill shown is composed of an upper balance unit and a lower balance unit. The upper balance unit and the lower balance unit are independent of each other. Adjusting the height position and elastic balance state of the rolling mill can better balance the self-gravity of the drive shaft of the rolling mill and the vibration generated during the rolling process. The upper bearing housing 4 for supporting the transmission shaft 7 on the rolling mill and the lower bearing housing 5 for supporting the lower transmission shaft 8 can only slide up and down in the transmission shaft bracket 3, and the two side walls of the transmission shaft bracket 3 are provided with The guide groove 3-1 matching the guide structures on both sides of the upper bearing seat 4 and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com