Neutron tube target structure with adjustable target distance

An adjustable, neutron tube technology, applied in the field of neutron tubes, can solve the problem of low utilization rate of target electrodes, and achieve the effects of simple structure, improved utilization rate and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

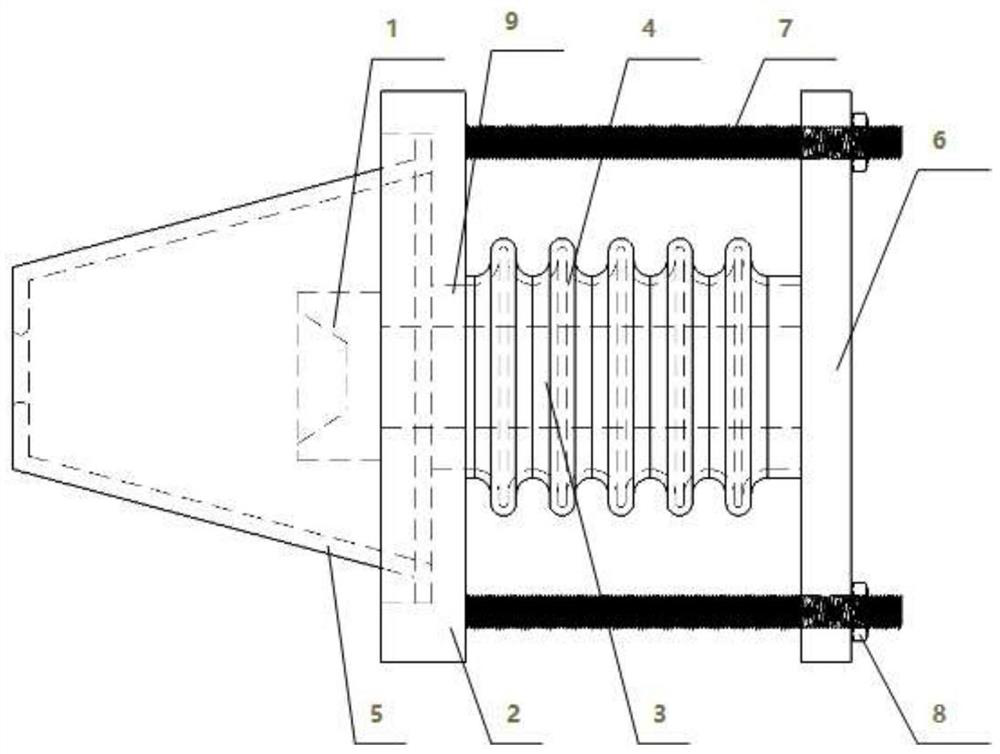

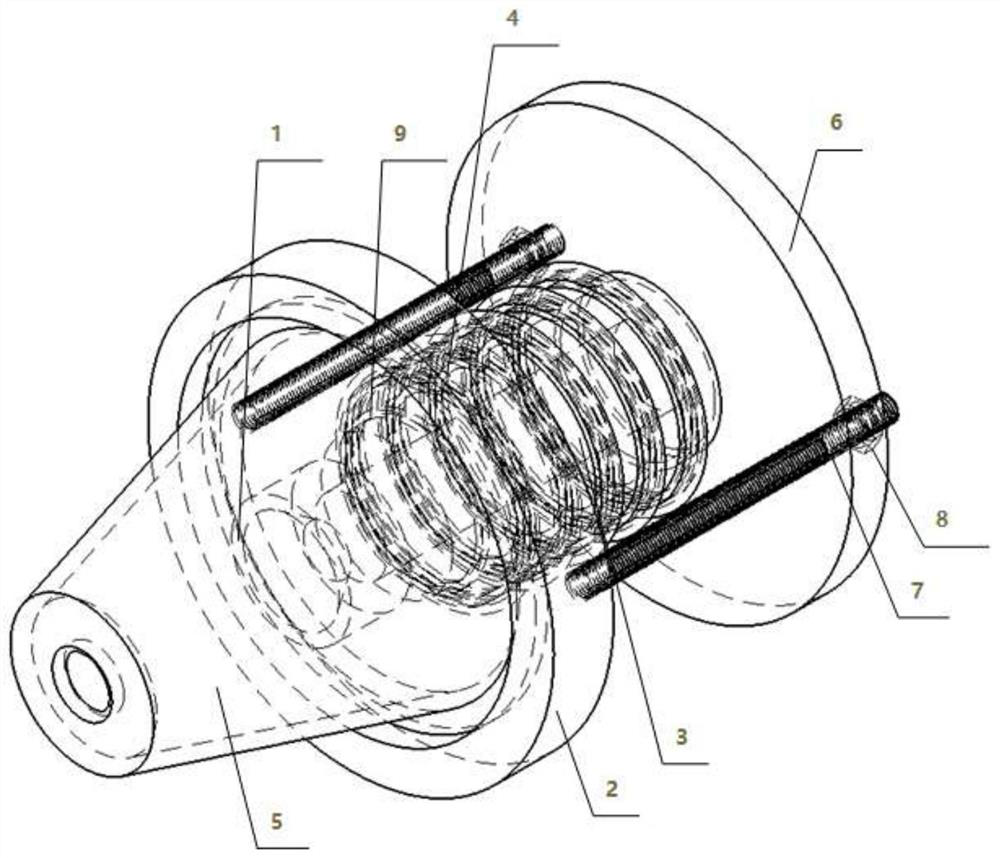

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0020] see figure 1 , figure 2 , a neutron tube target structure with adjustable target distance, including a target insulator 2, the outer side of the target insulator 2 is embedded with the outlet side of a Faraday cage 5, and the inner edge of the target insulator 2 passes through a screw 7 and a baffle plate 6 The edges are connected and fixed by nuts 8; a corrugated telescopic tube 4 is connected between the center of the target insulator 2 and the baffle 6, the pull rod 3 is sleeved in the inner cavity of the corrugated telescopic tube 4, and the fixed end of the pull rod 3 is connected to the baffle 6 The inner side is connected, and the free end of the tie rod 3 is connected with the connecting end of the target 1.

[0021] A hole 9 is opened in the middle of the target insulator 2 , and the diameter of the hole 9 is larger than the outer diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com