A kind of functional fabric production equipment and its process

A production equipment and functional technology, applied in the textile field, can solve problems such as fiber waste, achieve the effect of improving comfort and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

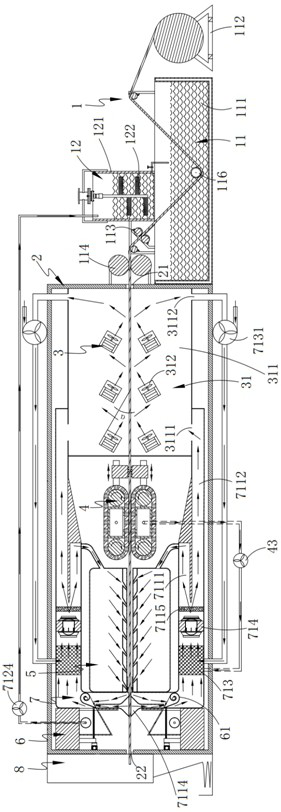

[0063] Such as figure 1 As shown, a functional fabric production equipment includes a sizing unit 1, a box body 2 connected to the tail end of the sizing unit 1, a dehumidification unit 3 arranged in the box body 2, a carding unit 4, a drying unit 5, Waste recycling unit 6, heating unit 7 and traction unit 8 located at one end of box body 2; said traction unit 8 includes a drive motor, a drive chain and a number of discharge rollers;

[0064] Both ends of the box body 2 are respectively provided with a feed port 21 and a discharge port 22;

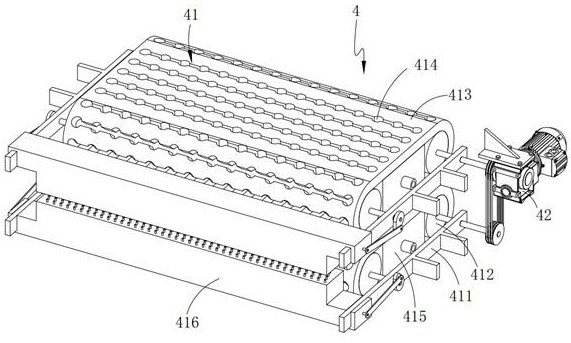

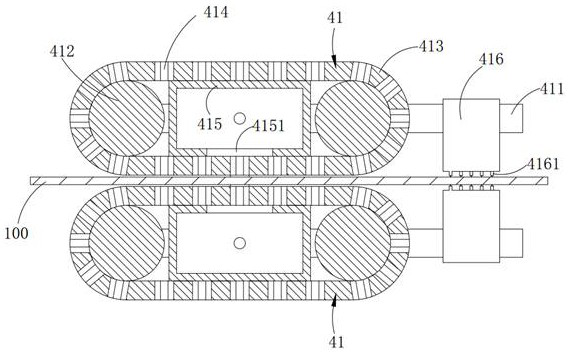

[0065] The carding unit 4 includes two sets of carding assemblies 41 arranged symmetrically up and down, and a drive assembly 42 and an adsorption assembly 43 connected to the two sets of carding assemblies 41;

[0066] Such as figure 1 As shown, the drying unit 5 includes an upper drying box and a lower drying box, the bottom of the upper drying box is provided with a number of air outlets a; the top of the lower drying box is provided ...

Embodiment 2

[0100] The production process of using a functional fabric production equipment described in the first technical solution of the above embodiment for producing functional fabrics includes the following steps:

[0101] Step 1, the fabric reel is fixed, the fabric 100 reel to be sized is fixed on the unwinding support 112, and the fabric 100 is pulled forward by using the traction system;

[0102] Step 2, slurry preparation, adding the fiber 200 into the mixing tank 121 in proportion, using the stirring paddle 122 to stir the slurry in the mixing tank 121, and adding it to the sizing tank 111 after the stirring is completed;

[0103] Step 3, sizing, when the fabric 100 passes through the sizing pool 111, the surface of the fabric 100 is subjected to sizing treatment; the fabric 100 is flattened by a flattening roller, and the excess material on the fabric 100 is extruded by a squeeze roller arranged behind the flattening roller. slurry, and simultaneously press the fiber 200 deb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com