Electric front water feeding pump system of indirect air cooling unit based on doubly-fed system

A technology of air-cooling units and feed water pumps, which is applied in the direction of steam engine devices, machines/engines, pumps, etc., can solve the problems of low operating efficiency, poor economy, and difficulty in meeting the operating needs of indirect air-cooling units, and achieve high regulation efficiency and floor space Small, the effect of improving the adjustment efficiency and the safety of the adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred implementation examples of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

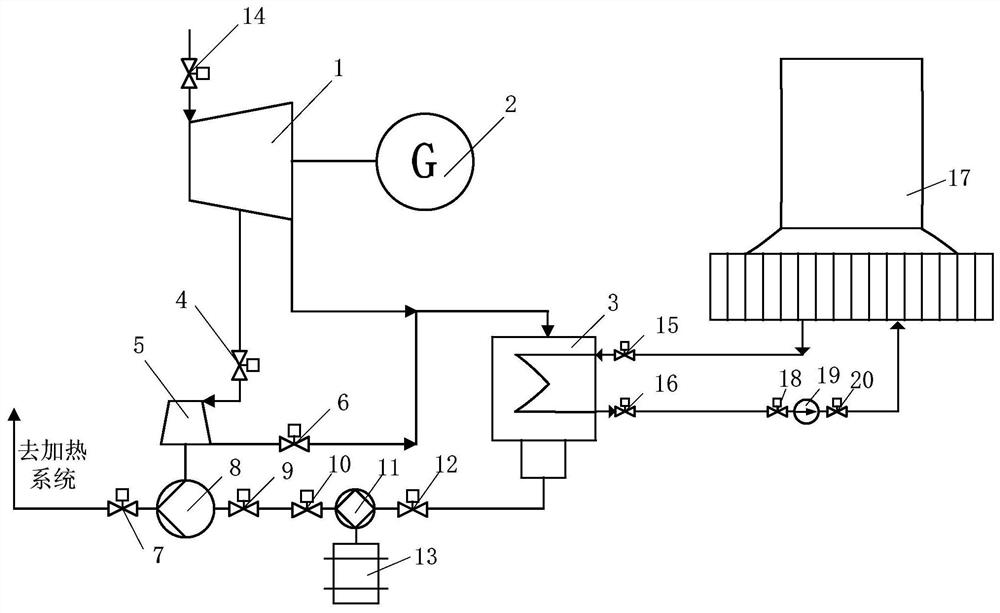

[0029] Such as figure 1 As shown, a doubly-fed system-based electric pre-feed water pump system for indirect air-cooled units provided by the present invention includes a steam turbine 1, a generator 2, a condenser 3, a small steam turbine 5, a feed water pump 8, and an electric pre-feed water pump 11. Double-fed motor 13, steel structure indirect air cooling tower 17 and circulating water pump 19; generator 2 is coaxially connected with steam turbine 1, small steam turbine 5 is coaxially connected with feed water pump 8, double-fed motor 13 is connected with electric front feed water pump 11 Coaxial connection; the exhaust steam outlet of st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com