Clamping Mechanism of Four-station Turntable of CNC Quenching Machine

A four-station turntable and clamping mechanism technology, applied in the direction of quenching device, clamping, manufacturing tools, etc., can solve the problems of low degree of automation, weak quenching conversion ability, unable to meet the stability of the upper and lower clamping positions, and achieve reasonable design , enhanced efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

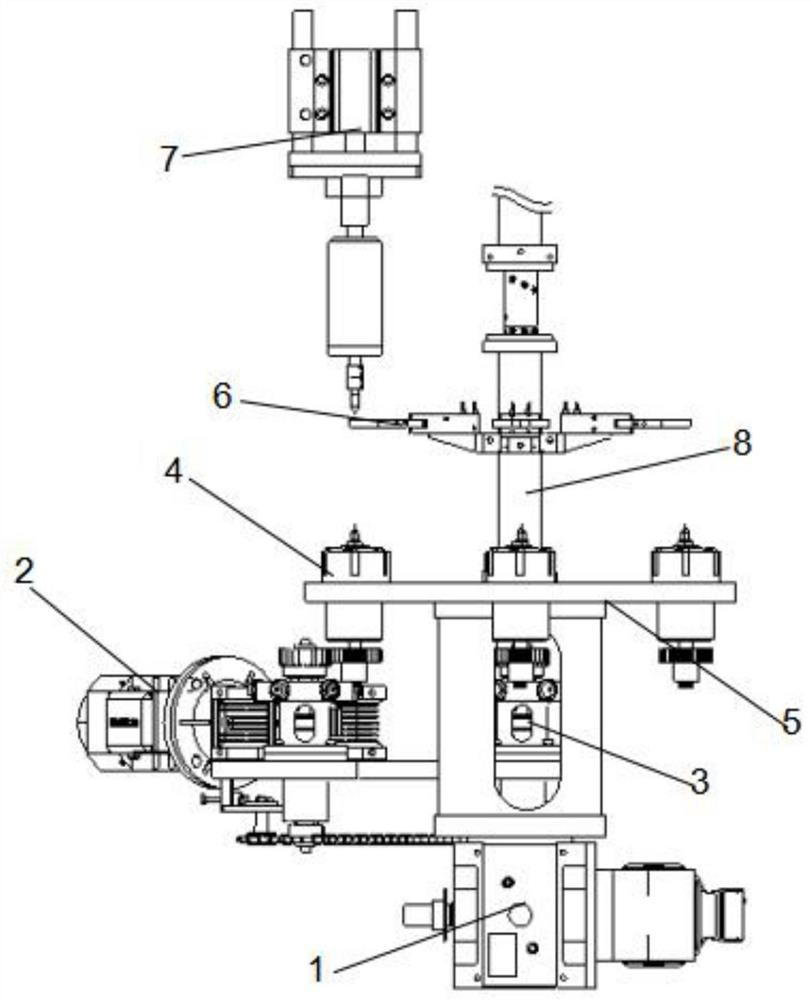

[0023] Embodiment: A four-station turntable clamping mechanism of a CNC quenching machine.

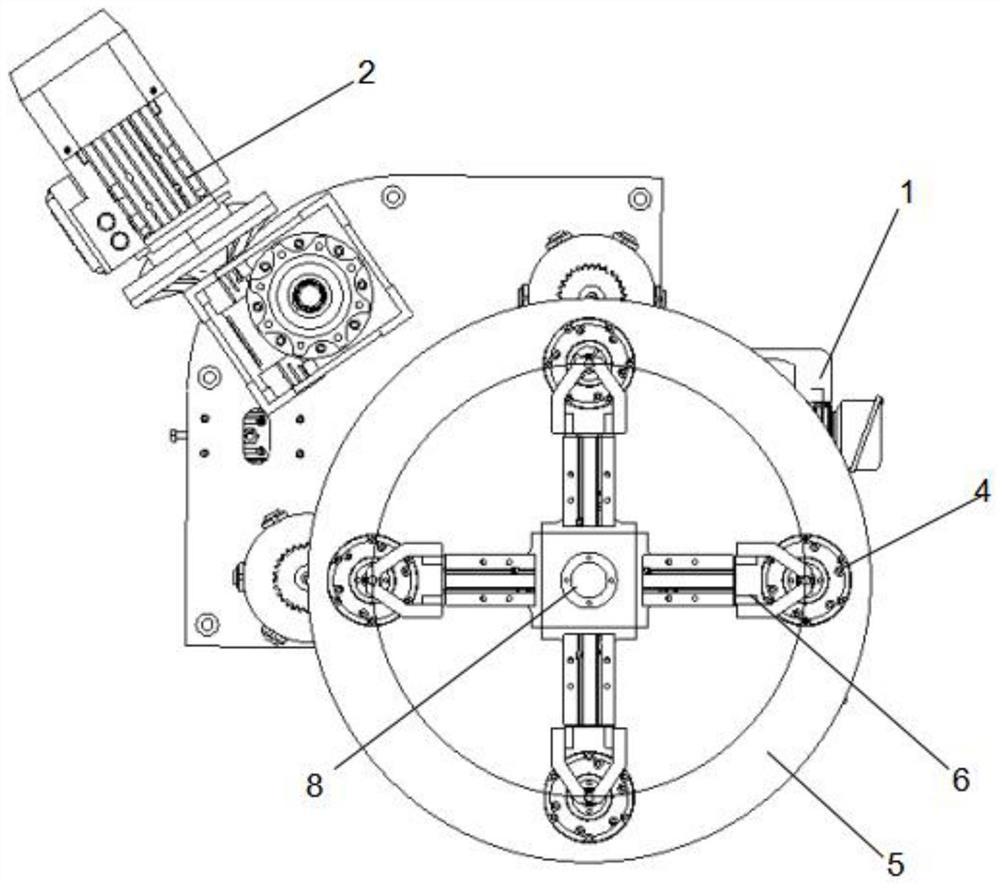

[0024] refer to Figure 1 to Figure 6 As shown, a four-station turntable clamping mechanism of a CNC quenching machine includes:

[0025] Four-station turntable 5;

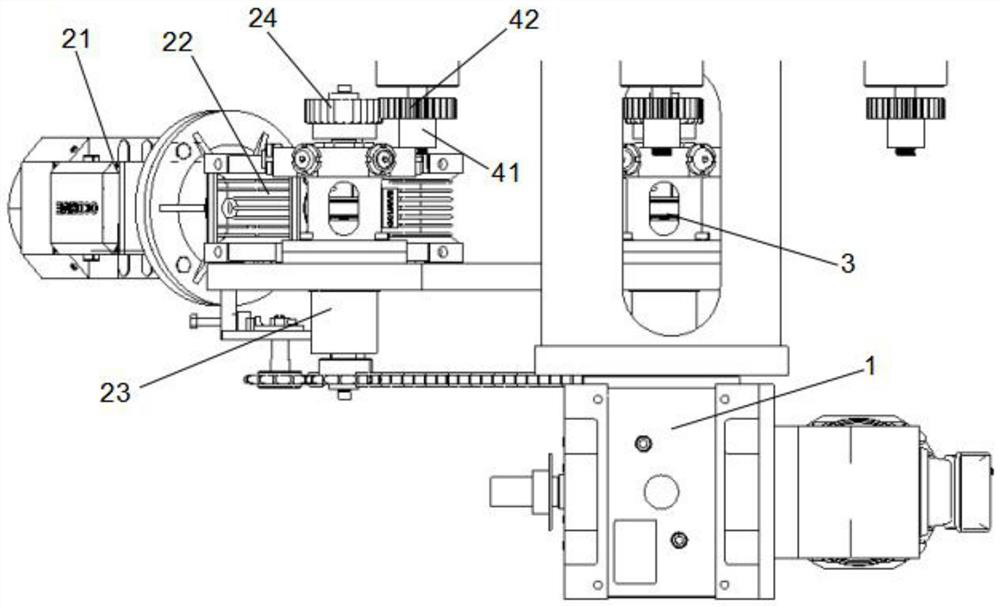

[0026] The turntable transmission device 1 installed under the four-station turntable 5 is connected with the four-station turntable 5 through the turntable transmission shaft 3. In this embodiment, the turntable transmission device 1 is a divider. The actual working process Among them, the turntable transmission device 1 can drive the four-station turntable 5 to rotate clockwise;

[0027] Four lower top assemblies 4 installed on the four-station turntable 5 in a circular array, the lower top assembly 4 includes a workpiece rotation transmission shaft 41, a workpiece rotation transmission gear 42, a lower top bearing 43, a lower ejector rod 44 and The lower tip 45, wherein the lower tip bearing 43 is fixed on the four-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com