System and process for deep dehydration of sludge by using ultrahigh pressure squeezer

A technology of deep dewatering and sludge dewatering, which is applied in water/sludge/sewage treatment, presses, sludge treatment, etc. It can solve the problem that it is difficult to reduce the moisture content of sludge to below 60%, increase the scale and quantity of main equipment, Problems such as low working efficiency of equipment, to achieve the effect of reasonable design of feeding structure, low cost and low conditioning cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

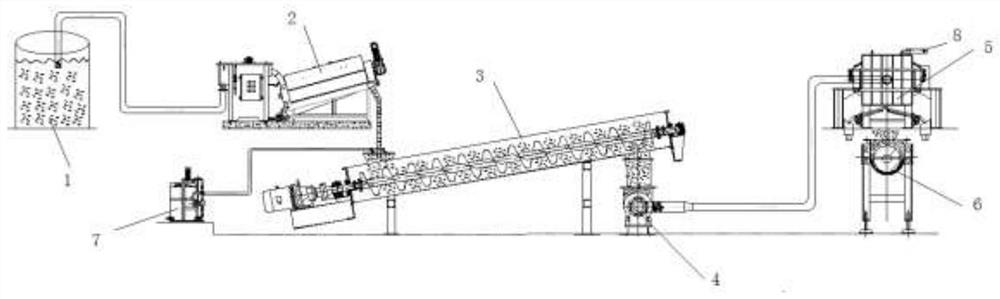

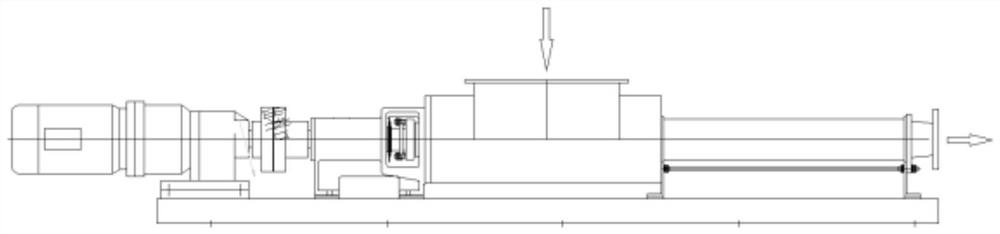

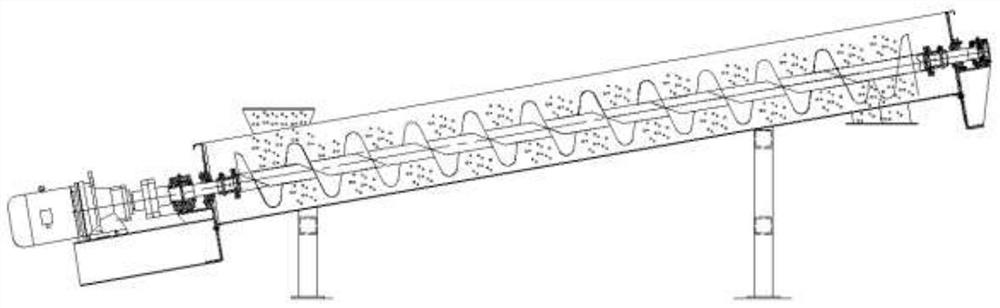

[0042] Such as Figure 1-Figure 8 As shown, the present invention is a treatment system for deep dehydration of sludge using an ultra-high pressure press, including a sludge tank 1, a first-stage sludge dewatering equipment 2, a sludge conditioning device 3, and a dry sludge conveying device 4 connected in sequence (dried mud feed pump), ultra-high pressure press 5 and the discharge mud conveying device 6, also include the quantitative dosing device 7 that is connected with the feed inlet of sludge conditioning device 3; A feed port 10 is provided on the side, that is, the feed end, and a back-blowing return pipeline 12 is provided above the feed port 10; The blowback port 11 is equipped with a full material test sensor 8 and a switch valve 9; the full material test sensor 8 is connected to the signal input end of the PLC control system, and the switch valve 9 is connected to the signal output end of the PLC control system; the sludge conditioning device 3 is selected Twin-sc...

Embodiment 2

[0054] Such as figure 1 As shown, the present invention is a treatment system for deep dehydration of sludge using an ultra-high pressure press, including a sludge tank 1, a first-stage sludge dewatering equipment 2, a sludge conditioning device 3, and a dry sludge conveying device 4 connected in sequence (dried mud feed pump), ultra-high pressure press 5 and the discharge mud conveying device 6, also include the quantitative dosing device 7 that is connected with the feed inlet of sludge conditioning device 3; The side, that is, the feed end is provided with a feed port 10, and the other side of the ultra-high pressure press 5 is provided with another feed port away from the feed end, and both feed ports are connected to the dry mud conveying device 4 (dry Mud feed pump) outlet connection; the blowback port of the ultra-high pressure press 5 is located in the middle of the ultra-high pressure press 5; the blowback port of the ultra-high pressure press 5 is provided with a ful...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com