Variable-rigidity robot joint structure

A technology of robot joints and stiffness, applied in the field of robots, can solve the problems of poor joint compliance, sacrifice cost, increased energy consumption, etc., and achieve the effects of compact adjustment mechanism, large transmission power, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below with reference to the accompanying drawings and examples.

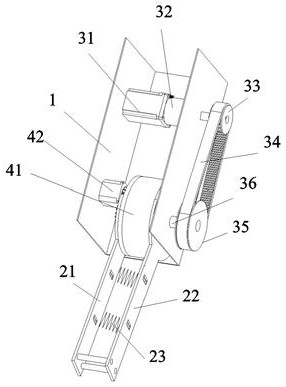

[0042] Append figure 1 Accompany Figure 5 As shown, a variable stereotic robot joint structure includes joint mechanism and variable rigidity adjustment mechanism 4, joint mechanism including first joint 1 and second joint 2, first joint 1 and second joint 2 passing A drive assembly 3 is connected such that the first joint 1 and the second joint 2 can be relatively rotated under the action of the first driving assembly 3;

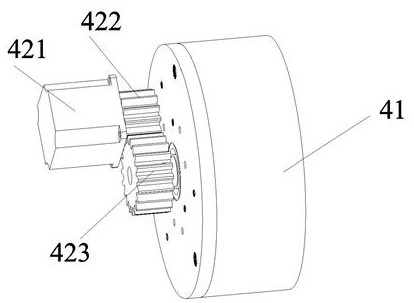

[0043] The variable rigidity adjustment mechanism 4 includes a housing 41 and a gear rack assembly, and the outer casing 41 is fixedly coupled to the second joint 2, and the gear rack assembly includes mutually engaging gear 47 and the rack 46, and the variable rigidity adjustment mechanism 4 also includes can be driven. The second drive assembly 42 rotates of the gear 47, the second drive assembly 42 is mounted on the joint mechanism, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com