Industrial robot program logic mistake proofing method

An industrial robot, program logic technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve problems such as software logic confusion, improve work efficiency, avoid suction cups colliding with other equipment, and reduce maintenance difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

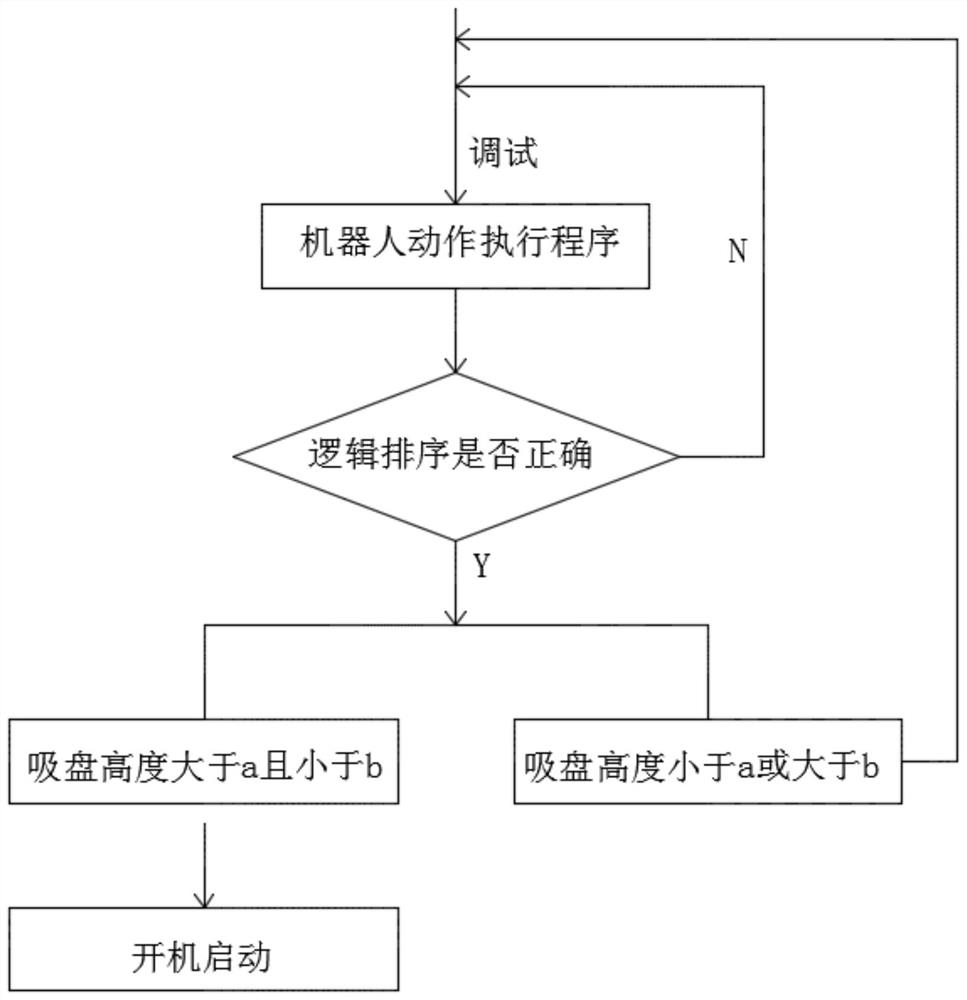

[0048] Such as Figures 1 to 3 As shown, this embodiment provides an error-proofing method for industrial robot program logic. The industrial robot is a diffusion rewind robot. The operating range of the suction cup is between a and b, where a<b. After the maintenance personnel debug, the calibration is performed. The calibration method is as follows:

[0049] (1) First, verify the debugged program. The specific verification method is to verify whether the logical order of the program is correct. If it is correct, go to step (2), if it is wrong, go to step (3) ;

[0050] (2) Check the operating height of the suction cup. If the height of the suction cup is greater than a and less than b, you can load the program and proceed to step (4). If the height of the suction cup is less than a or greater than b, proceed to step (3). step;

[0051] (3) Debug the program again, then repeat steps (1) and (2);

[0052] (4) Power on and start.

[0053] Working principle: Logically sort ...

Embodiment 2

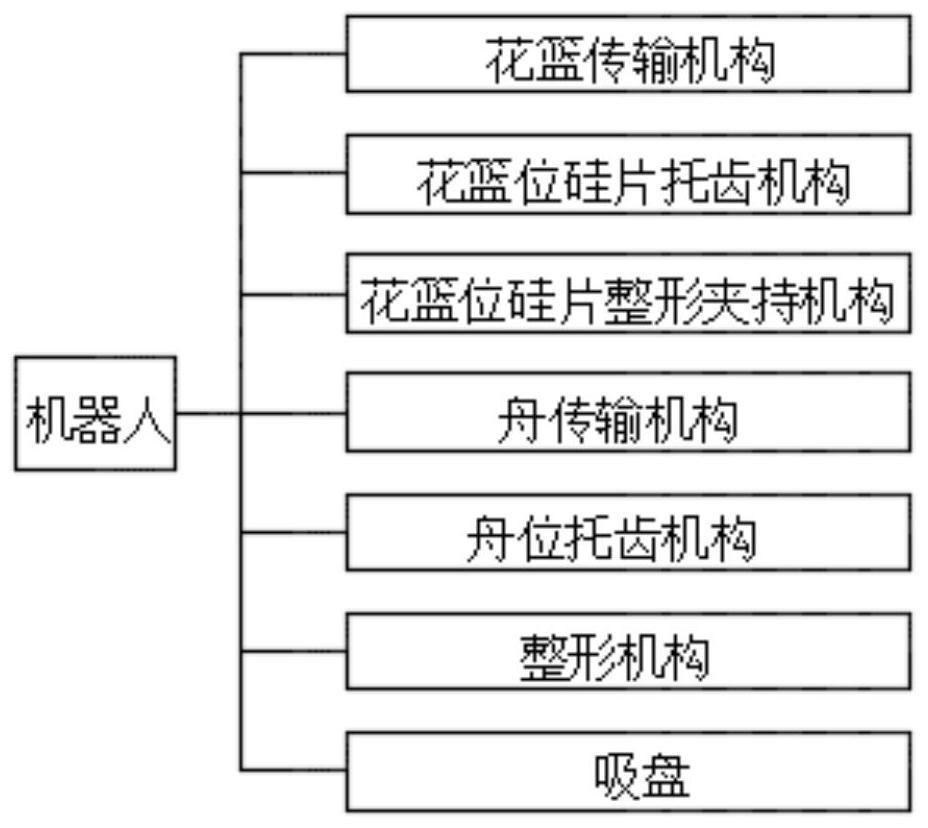

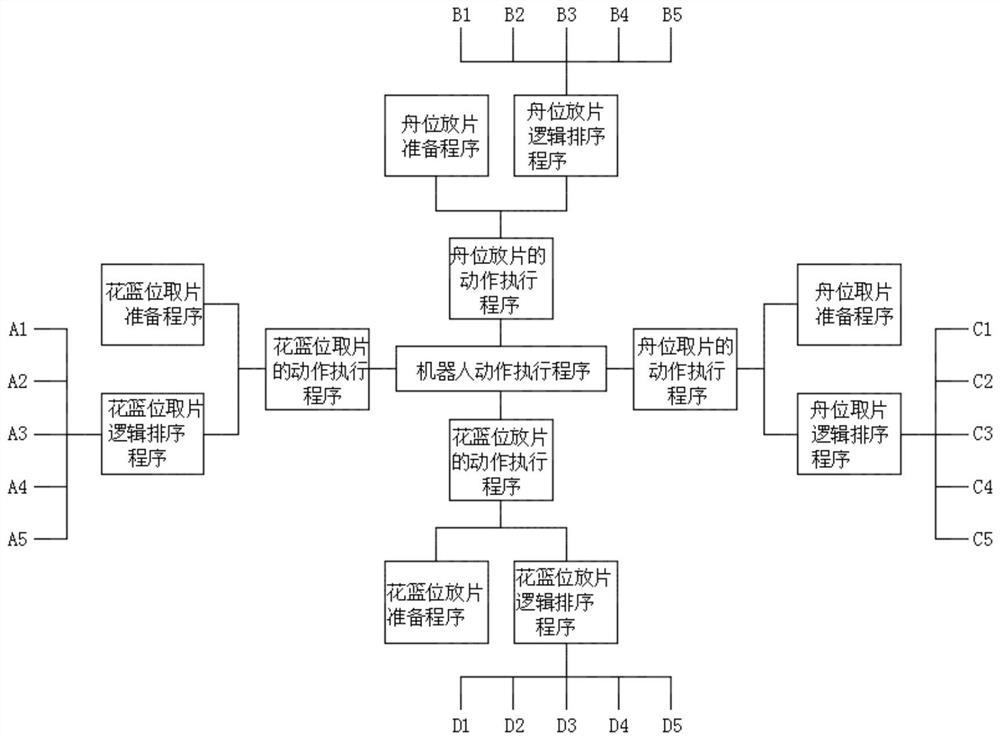

[0055] Such as Figures 1 to 3 As shown, this embodiment has been further improved on the basis of Embodiment 1. Specifically, the diffusion rewinding robot includes a flower basket transmission mechanism, a flower basket position silicon wafer support tooth mechanism, a flower basket position silicon wafer shaping and clamping mechanism, a boat transmission Mechanism, boat position tooth support mechanism and shaping mechanism, combined with the above mechanisms, the action execution program of taking the film in the basket position, the action execution program of placing the film in the boat position, the action execution program of taking the film in the boat position and the action execution program of placing the film in the basket position Logical sorting in sequential order.

Embodiment 3

[0057] Such as Figures 1 to 3 As shown, this embodiment has made further improvements on the basis of Embodiment 2. Specifically, the action execution program for taking pictures in the flower basket position includes a preparation program for taking pictures in a flower basket and a logic sorting program for taking pictures in a flower basket. The preparation for taking pictures in a flower basket The program is used to sequentially execute the flower basket output mechanism to transfer the flower basket to the predetermined position, the material supporting mechanism to lift the flower basket silicon wafer to the predetermined position, and the shaping mechanism to complete the shaping and wait for the robot to take the film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com