A kind of high adsorption oil fume purification treatment equipment

A technology for oil fume purification and treatment equipment, which is applied in the direction of oil fume removal, lighting and heating equipment, chemical instruments and methods, etc., which can solve problems such as effective cleaning, inability to obtain attachments, and decline in oil fume filtration and purification effect, so as to increase the service life , Improve the degree of purification, quick dismantling and cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

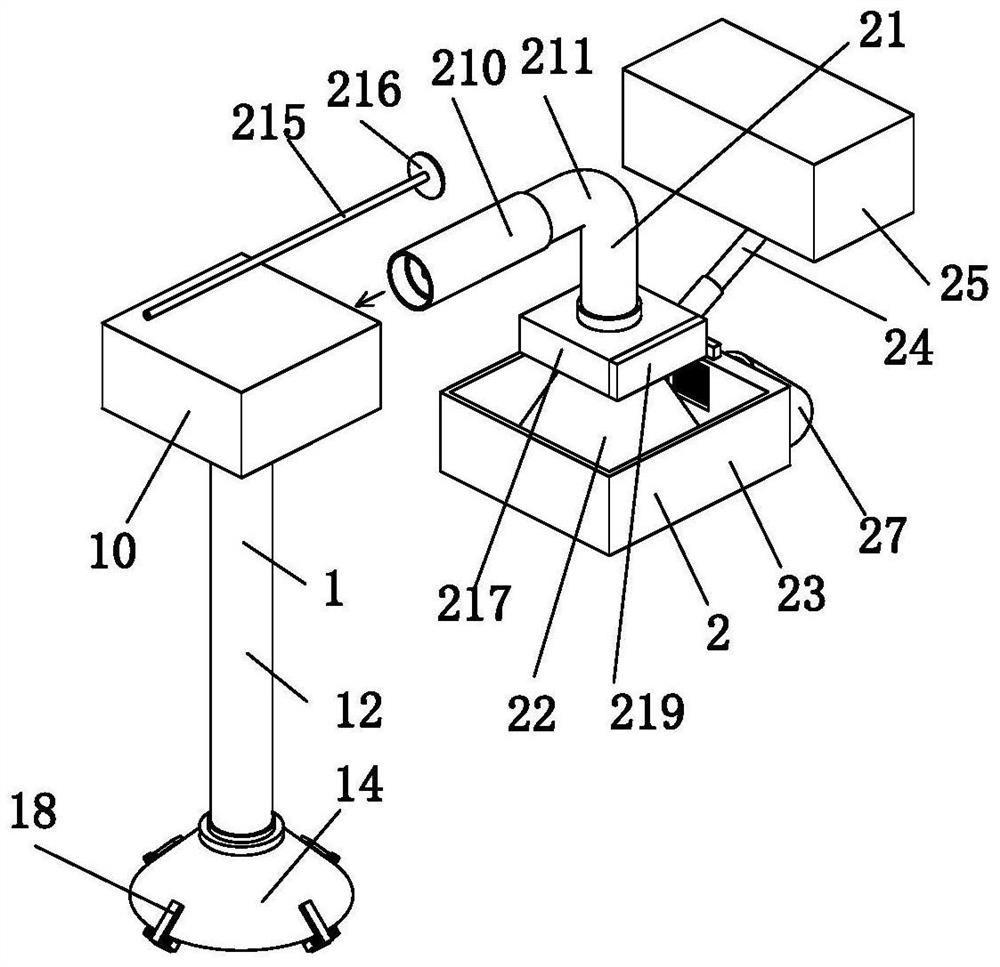

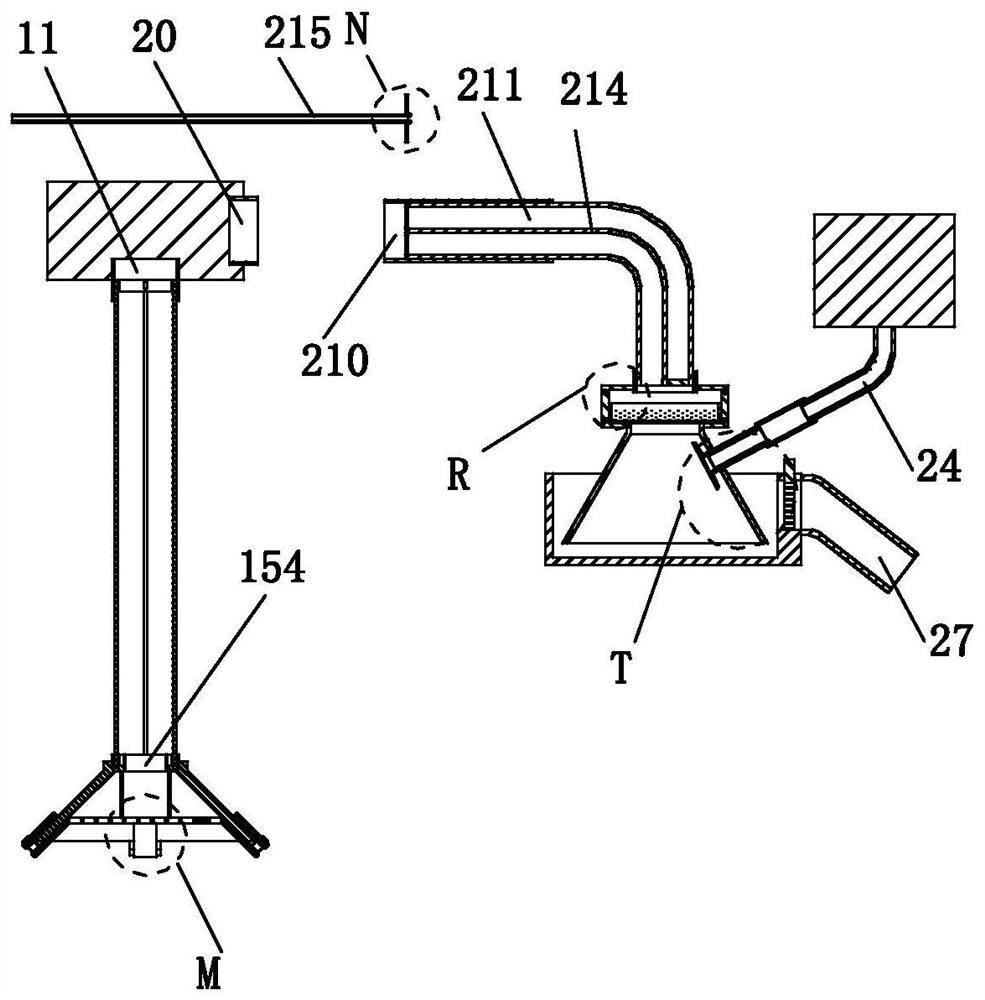

[0036] Such as Figure 1 to Figure 13 As shown, a kind of high adsorption oil fume purification treatment equipment includes a suction filter mechanism 1 and a spray mechanism 2. The spray mechanism 2 is arranged on the right side of the upper end of the suction filter mechanism 1. The shower mechanism 2 is flexibly connected with the existing body of wall.

[0037] The suction filter mechanism 1 includes a suction machine 10, a No. 1 ring 11, a standpipe 12, a No. 2 ring 13, a trumpet head 14, a round filter plate 15, a No. 1 splint 16, a No. 1 ear plate pair 17, No. 2 splint 18 and torsion spring 19, the rear end of the suction machine 10 is connected with the existing wall by the No. 1 bolt, and the middle part of the lower end of the suction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com