Hidden self-destruction needle head

A hidden, self-destructing technology, applied in the field of injection needles, can solve problems such as unfavorable injection, patient fear, disease transmission, etc., to avoid reuse, improve safety performance, and have good market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

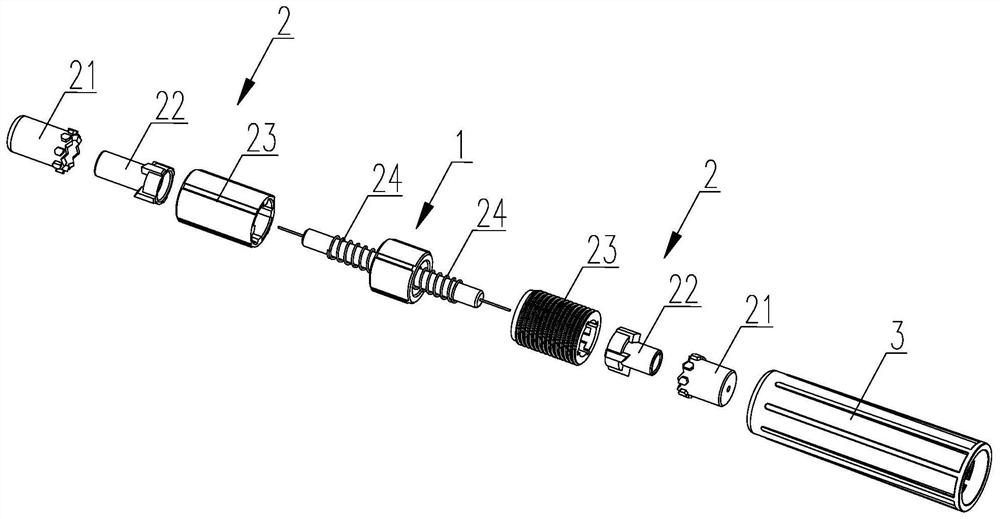

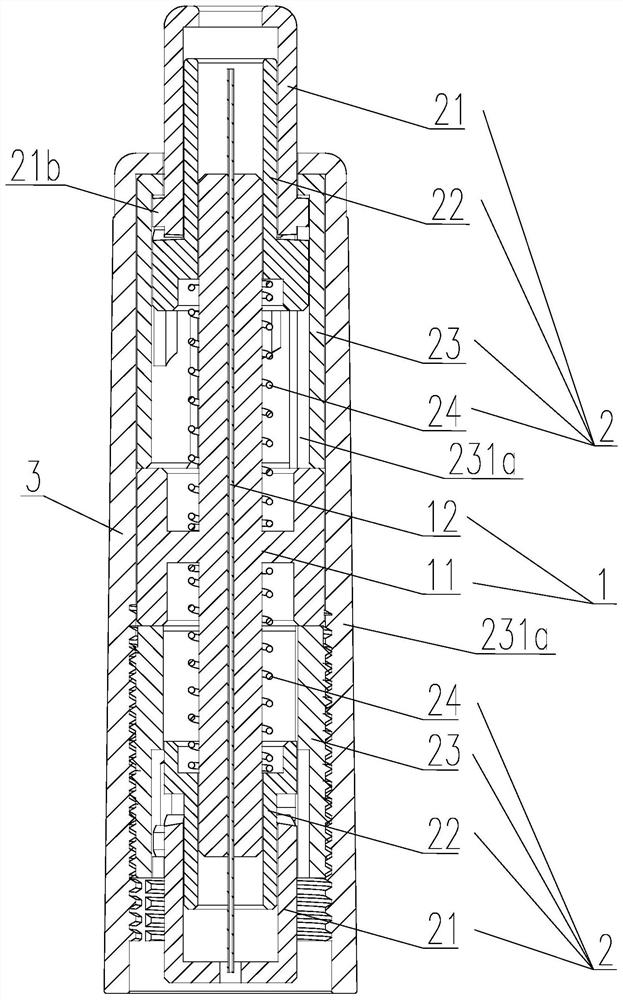

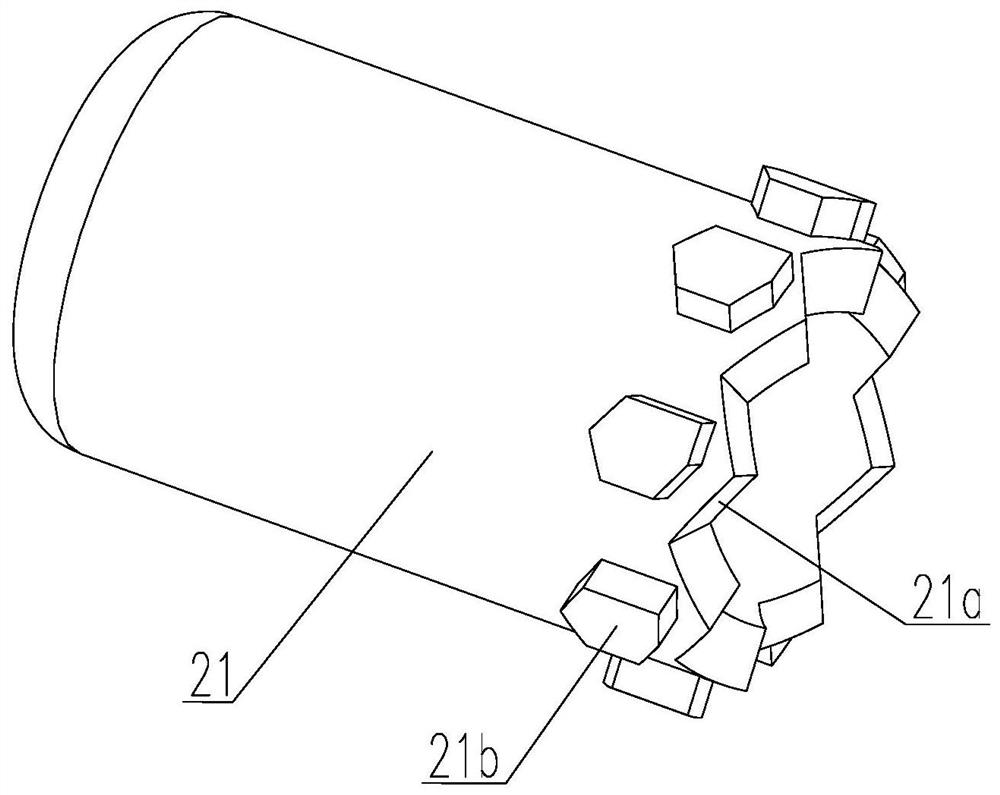

[0039] Such as Figure 1-11 As shown, a hidden self-destructing needle includes an injection needle 1 and a hidden needle device 2. The hidden needle device 2 includes a hidden needle cap 21, a protective cap 22, a guide sleeve 23 and an elastic element 24. The guide sleeve 23 Fixed on the injection needle 1, the protective cap 22 is movably arranged on the guide sleeve 23, the hidden needle cap 21 is slidably installed on the protective cap 22, and one end of the injection needle 1 is located in the protective cap 22; The guide sleeve 23 is provided with a slot group 231, the slot group 231 includes a guide slot 231a and a locking slot 231c whose inner ends communicate with each other, a partition 231b is formed between the guide slot 231a and the locking slot 231c, The protective cap 22 has a tooth post 22a, and the tooth post 22a is located in the guide groove 231a;

[0040] When the outer end of the tooth column 22a contacts the inner end of the hidden needle cap 21, a fi...

Embodiment 2

[0056] The difference between embodiment 2 and embodiment 1 is that the hidden needle device 2 of the hidden self-destruct needle has one and is located at the needle tail end of the injection needle 1, that is, the needle tail end of the injection needle 1 is located at the protective cap 22 of the hidden needle device 2 Inside; when the injection needle 1 is connected to the syringe, the protective cap 22 at the end of the injection needle 1 will be pushed inward by the syringe, and its hiding and self-destruct principle is consistent with that of Example 1, except that the protective cap in Example 1 22 relies on its own axial inward displacement when it is against the human body, while the protective cap 22 in this embodiment relies on its own axial inward displacement when it is connected with the syringe.

Embodiment 3

[0058] The difference between embodiment 3 and embodiment 1 is that there are two hidden needle devices 2, and the two hidden needle devices 2 are respectively located at both ends of the injection needle 1; The guide sleeve 23 and the injection needle 1 are fixed in the housing 3; in this way, both ends of the injection needle 1 are hidden, the safety of use is improved, and a better self-destruct effect is achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com