A vegetable seedling raising device that can automatically and accurately and quantitatively plant

A seedling raising device and precise technology, applied in sowing, planting methods, planter parts, etc., can solve the problems of vegetable seed waste, affecting the germination rate of seeds, reducing the germination rate of vegetable seedlings, etc. Guaranteed germination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A vegetable seedling raising device that can automatically and accurately and quantitatively plant, such as figure 1 and figure 2 As shown, it includes a support frame, a pressing mechanism, a pressing hole mechanism and a seeding mechanism. The support frame includes a front bracket 1, a rear bracket 101, a first bracket 102, a second bracket 103, a third bracket 104 and a horizontal connecting plate 105. The front bracket 1 and the rear bracket 101 are symmetrically arranged in the front and rear, the first bracket 102, the second bracket 103, the third bracket 104 and the horizontal connecting plate 105 are all arranged in two, and the lower ends of the two first brackets 102 are respectively fixedly connected to the The upper and outer sides of the front bracket 1 and the rear bracket 101, the lower ends of the two second brackets 103 are respectively fixedly connected to the upper and outer sides of the front bracket 1 and the rear bracket 101, and the lower ends ...

Embodiment 2

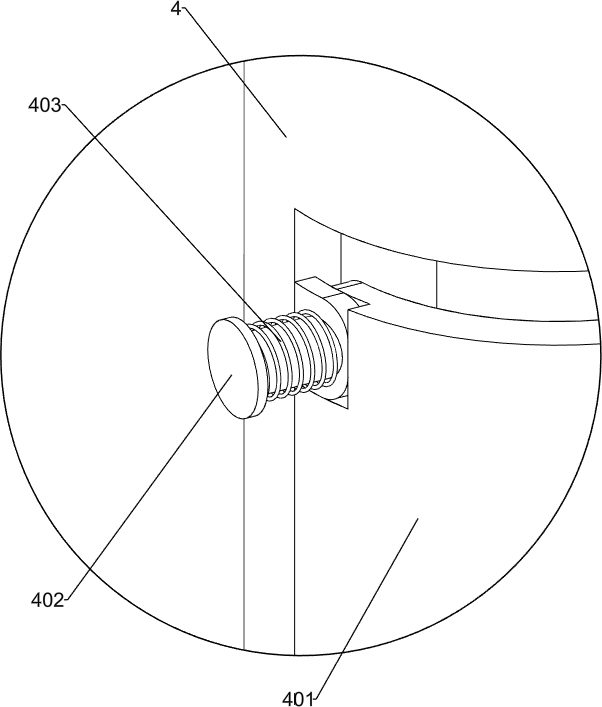

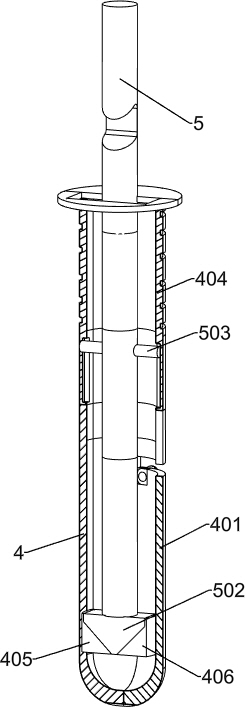

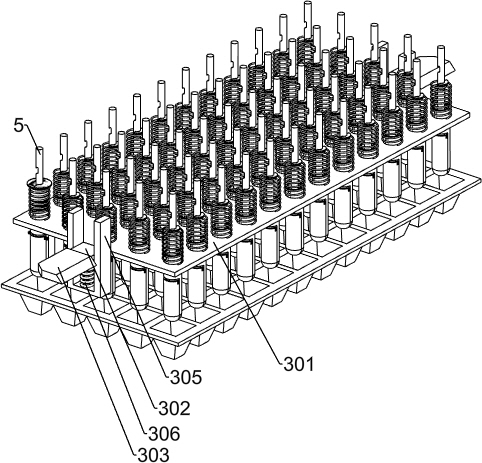

[0035] On the basis of Example 1, as Figure 2-Figure 10 As shown, the pressing mechanism includes a seed chamber 3, a pressing plate 301, a fixed sliding plate 302, a sliding sleeve 303, a second spring 304, a sliding frame 305 and a fourth spring 306, and both ends of the seed chamber 3 are fixedly connected to the two On the upper ends of the two brackets 103, the pressing plate 301 is arranged below the seed chamber 3, and there are two sliding frames 305. The upper ends of the two sliding frames 305 are respectively fixedly connected to the two ends of the lower side of the seed chamber 3, and the fixed sliding plates 302 are arranged as two The inner ends of the two fixed sliding plates 302 are respectively fixedly connected to the front and rear ends of the pressing plate 301, the fixed sliding plates 302 are slidably connected to the sliding frame 305, two fourth springs 306 are arranged, and two fourth springs 306 are arranged at two Inside the sliding frame 305 , the...

Embodiment 3

[0041] On the basis of Example 2, as figure 2 , image 3 and Figure 11 As shown, the power mechanism includes an electric push rod 2, a fixed sleeve 201, a vertical connecting plate 202, a fixed frame 203, a sliding rod 204, a first spring 205, a first rack 206, a first connecting frame 207, a connecting bar 208 and The triangle plate 209, the fixed sleeve 201 is fixedly connected to the upper ends of the two first brackets 102, the electric push rod 2 is fixedly connected to the fixed sleeve 201, the upper end of the vertical connecting plate 202 is fixedly connected to the top rod of the electric push rod 2, the upper part of the fixed frame 203 is fixedly connected The side middle position is fixedly connected to the lower end of the vertical connecting plate 202 , the right end of the first rack 206 is fixedly connected to the front end of the fixing frame 203 , two sliding rods 204 and two first springs 205 are respectively provided, and the right ends of the two slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com