Combustion power generation furnace and power generation and charging method thereof

A technology of combustion power generation and thermoelectric power generation sheet, which is applied in the direction of generators/motors, electrical components, etc., and can solve the problems of low efficiency of biomass power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

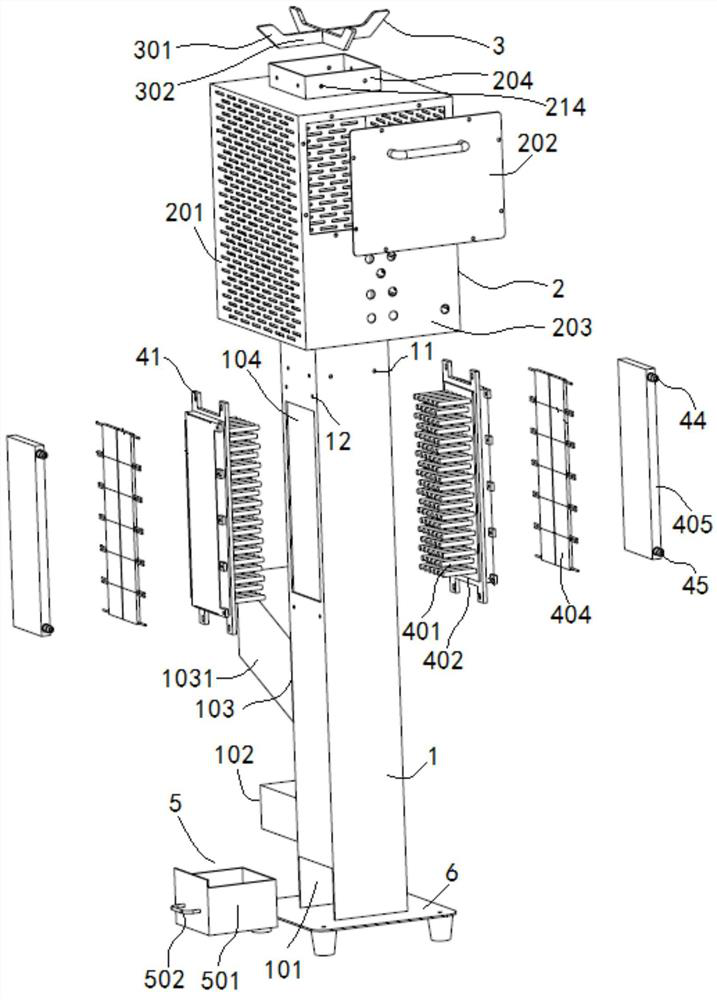

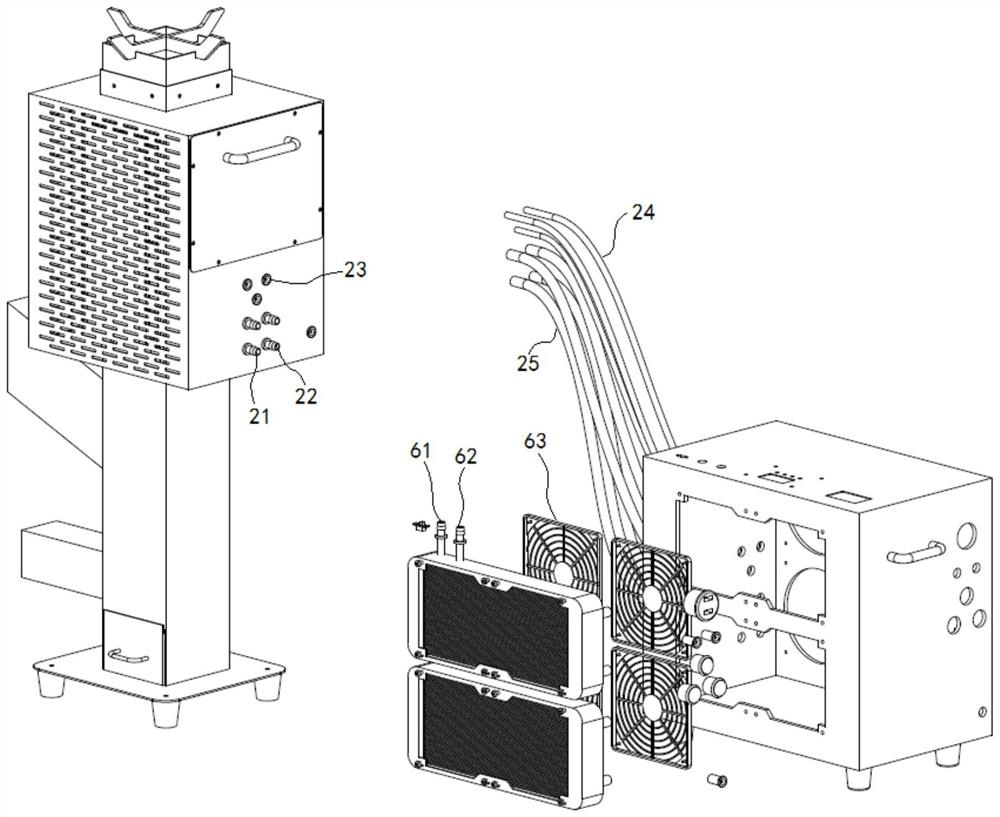

[0034] combined with Figure 1-2 , a combustion power furnace, comprising: a furnace body 1, an air port 102 arranged on the furnace body 1 for circulating gas; a fuel inlet 103 arranged on the furnace body 1; an opening 104 arranged on the furnace body 1 for The thermoelectric converter 4 is installed; the thermoelectric converter 4 includes a thermal conductor 41 connected to the hot end of the thermoelectric converter 4, and a heat sink 405 connected to the cold end of the thermoelectric converter 4; the thermal conductor 41 is located in the body of the furnace 1; the heat sink 405 is located outside the furnace body 1; the opening 104 is higher than the fuel inlet 103.

[0035] The fuel inlet 103 is used to conveniently put into the body of heater 1 biomass fuels, solid fuels, such as firewood, briquettes, etc. The types of fuels that can be thrown in the fuel inlet 103 are various, and are not limited by the present embodiment; The fuel is burned in the furnace body 1, ...

Embodiment 2

[0057] A combustion power generation method, according to a combustion power furnace described in any one of the technical solutions in Embodiment 1, comprising: the heat conduction member 401 absorbs the heat generated by the combustion of fuel in the furnace body 1; the heat transferred to the thermoelectric converter 4 There is a temperature difference with the cold end of the thermoelectric converter 4; the thermoelectric converter 4 generates electric energy.

Embodiment 3

[0059] A method for charging a combustion power furnace, according to any one of the technical solutions in Embodiment 2, comprising: the electric energy generated by the thermoelectric converter 4 is used to charge electrical equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com