A hairpin winding forming device for electric vehicle drive motor

A technology for driving motors and electric vehicles, applied in electric vehicles, manufacturing motor generators, electric components, etc., can solve problems such as difficulty in ensuring winding consistency, complex winding processing technology, and increased manufacturing costs, achieving good practicability and Operability, reduction of molding cost, effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

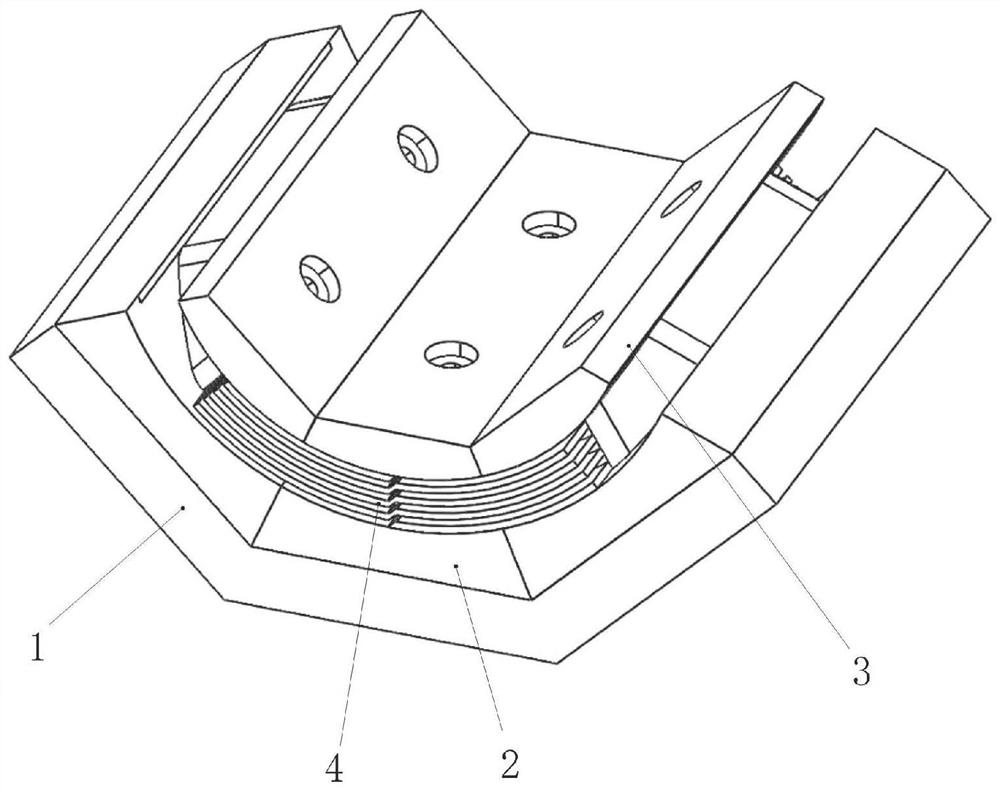

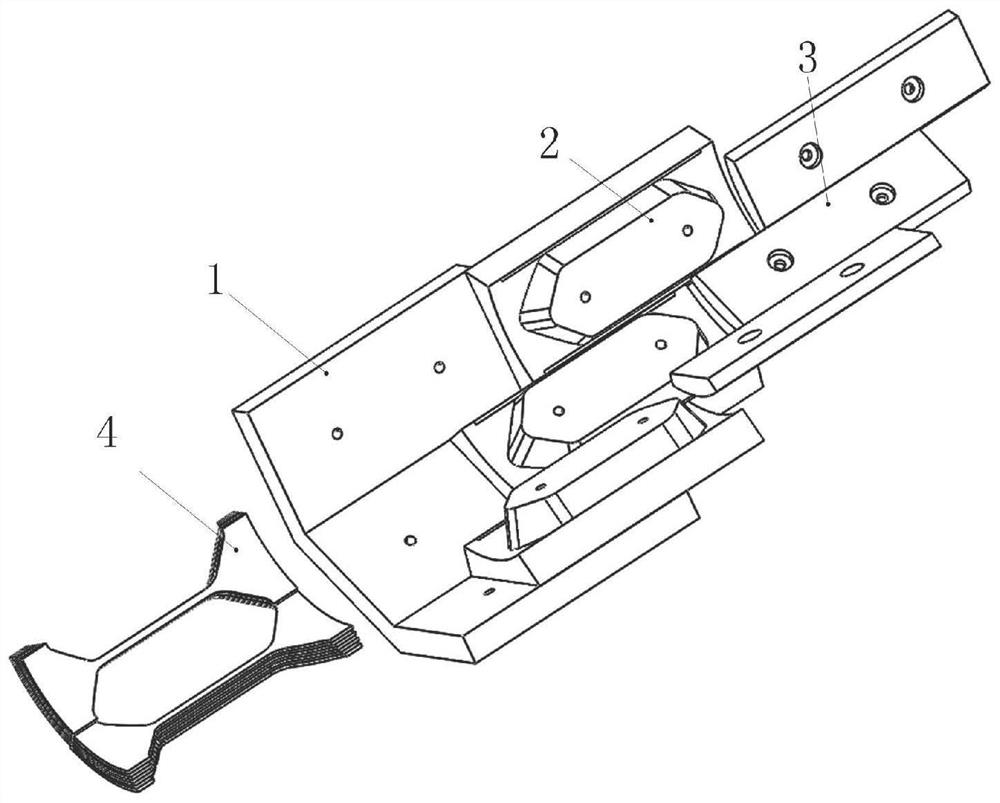

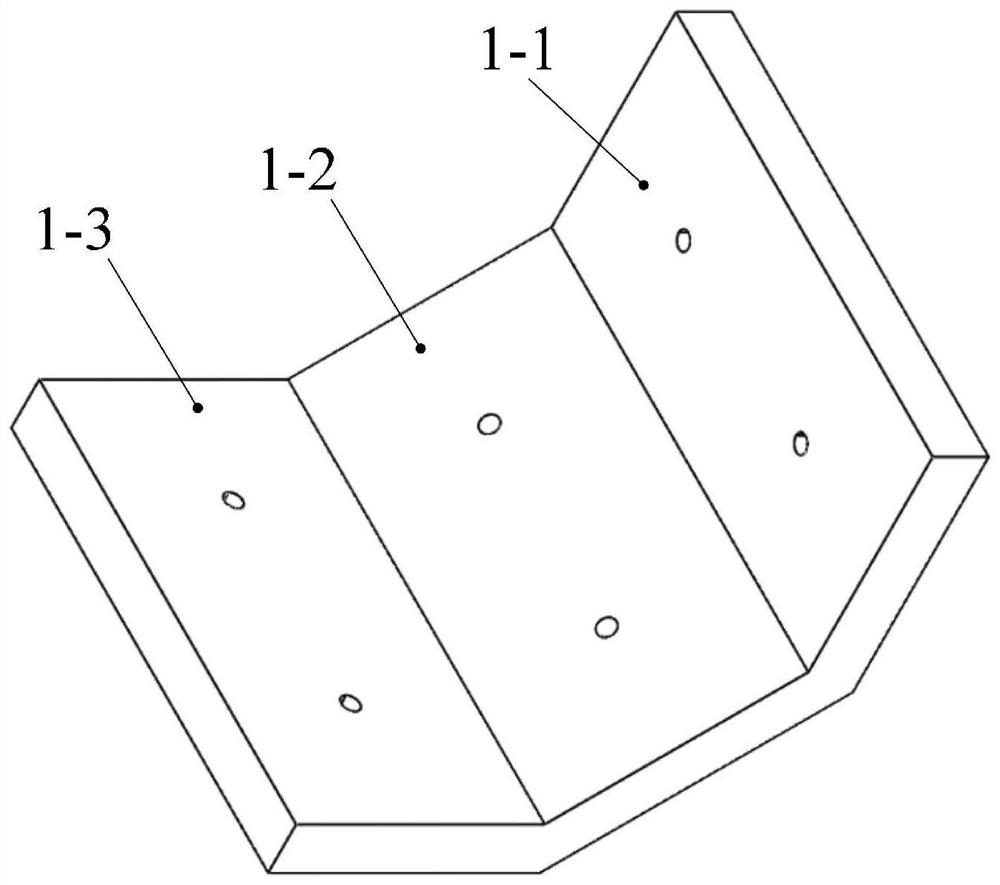

[0032] see Figure 1-15 Description of this embodiment, a hairpin winding forming device for electric vehicle drive motors, which includes a base 1, a wire mold 2, a cover mold 3 and a pad mold 4, and the wire mold 2 includes a boss 2-1 and a bottom plate 2- 2. The boss 2-1 is arranged on the bottom plate 2-2, the boss 2-1 and the bottom plate 2-2 are an integrated structure, and the cover mold 3 includes a groove 3-1 and a body 3-2 , the groove 3-1 is arranged on the lower end surface of the body 3-2, the groove 3-1 and the body 3-2 are an integrated structure, and the boss 2-1 has the same shape as the groove 3-1 , the pad mold 4 includes an upper end pad 4-1, a lower end pad 4-3 and a plurality of intermediate pads 4-2, the plurality of intermediate pads 4-2 are stacked on e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com