Multi-core panda structure polarization maintaining optical fiber and coupling connection device thereof

A polarization-maintaining fiber and coupling connection technology, applied in the field of optical communication transmission, can solve the problem of difficulty in maintaining the polarization state of light waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

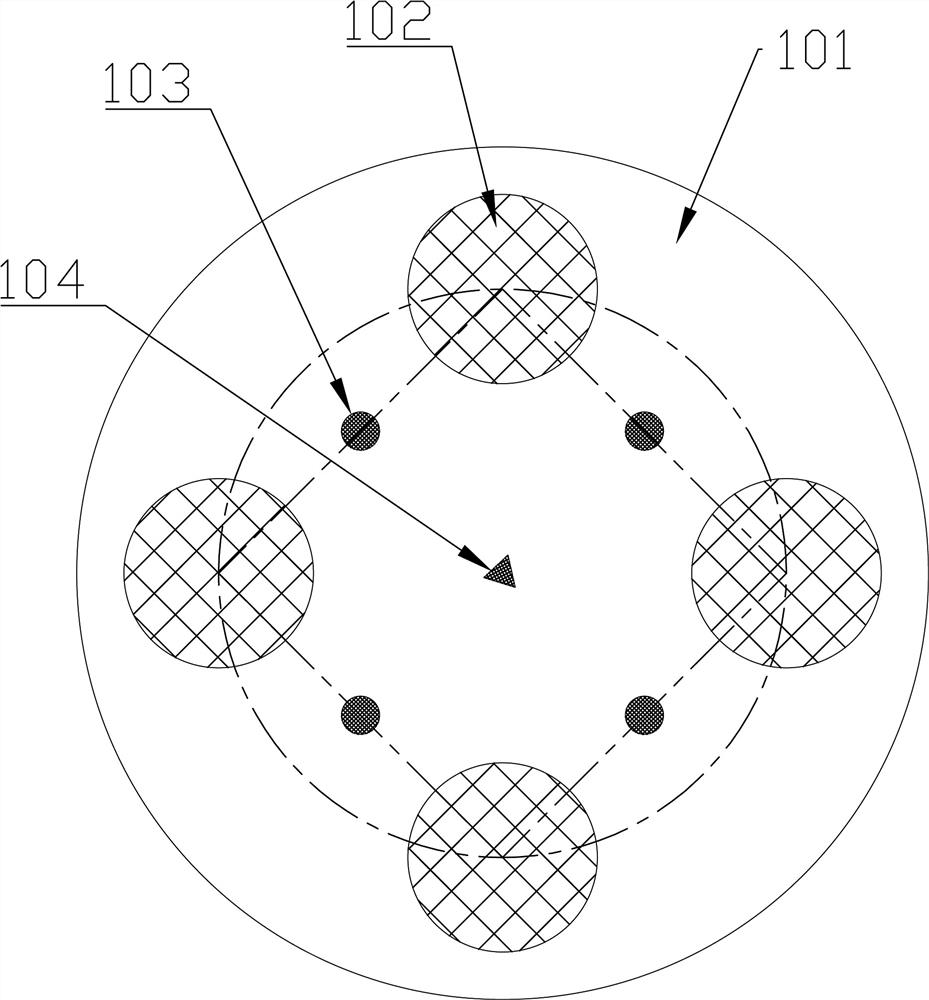

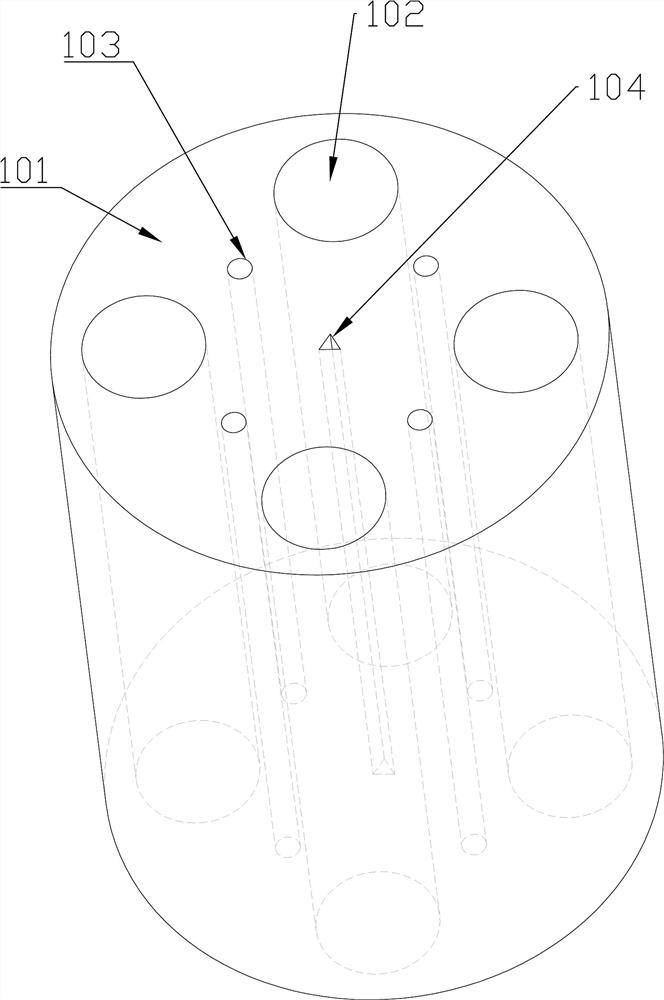

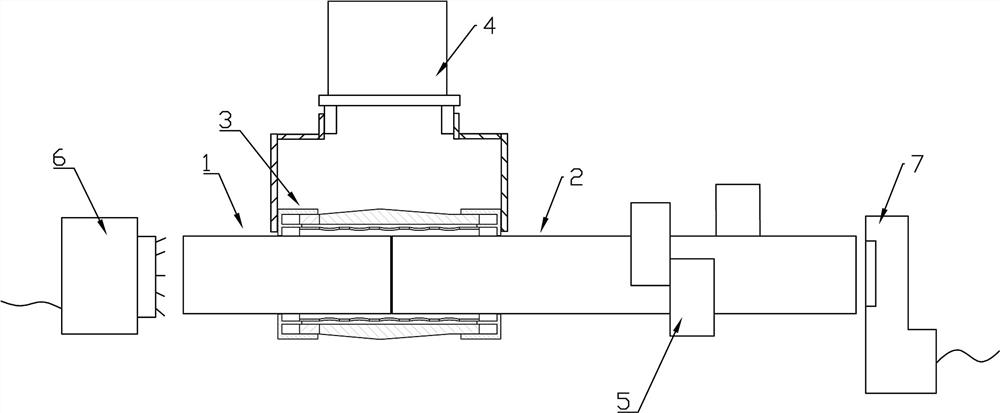

[0039] like Figure 1-11 Among them, a polarization-maintaining optical fiber with a multi-core panda structure includes a core layer and a stress layer coaxially arranged, the stress layer includes a plurality of stress rods 102 uniformly distributed in the circumferential direction, the core layer includes a plurality of fiber cores 103 uniformly distributed in the circumferential direction, and the fiber core 103 A cladding 101 is provided at the midpoint of the line connecting adjacent stress rods 102 , and the cladding 101 covers the stress rods 102 and the fiber core 103 .

[0040] Taking the stress layer including four stress rods as an example, the diameter D1 of the stress rods is 5 μm to 30 μm, the diameters of the four stress rods can be the same, or they can be the same in pairs, and the composition material is Ge, P, F, B co-doped quartz glass, where The molar percentage of Ge is 0-18, the molar percentage of P is 0-13, the molar percentage of F is 0-22, and the m...

Embodiment 2

[0067] A multi-core Panda structure polarization-maintaining optical fiber, including a core layer, a stress layer, a cladding layer, and a marking area. The stress layer is divided into four stress rods, all of which have the same diameter, and the composition materials and doping concentrations are the same in pairs, Symmetrically distributed in the cross region of the central axis of the cladding, the core layer is divided into four cores, and each core is located at the midpoint of the line connecting two adjacent stress rods;

[0068] The parameters are as follows:

[0069] The stress layer consists of four identical stress rods with a diameter D1 of 30 μm, composed of SiO 2 and B 2 o 3 , where two stress rods of SiO 2 The molar content is 80%, B2O 3 The molar content is 20%,

[0070] SiO with two stress bars on opposite sides 2 The molar content of B is 90%, B 2 o 3 The molar content is 10%, the core layer includes 4 identical cores, the diameter D2 is 8μm, they ...

Embodiment 3

[0074] A multi-core Panda structure polarization-maintaining optical fiber, including a core layer, a stress layer, a cladding layer, and a marking area. The stress layer is divided into four stress rods, the diameters of which are the same in pairs, and the doping concentration of the materials composed of the four stress rods is uniform. Similarly, the core layer is divided into four cores, and each core is located at the midpoint of the line connecting two adjacent stress bars;

[0075] The parameters are as follows:

[0076] The stress layer consists of four identical stress rods, two of which are 36 μm in diameter and two on the opposite side are 30 μm in diameter, composed of SiO 2 and B 2 o 3 , stress bar SiO 2 The molar content of B is 80%. 2 o 3 The molar content is 20%; the core layer includes four identical cores with a diameter D2 of 8 μm, which are respectively located at the midpoint of the line connecting two adjacent stress rods, and the composition materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com