Steel plate bending resistance detection device for construction sites

A construction site and detection device technology, applied to measuring devices, using stable bending force to test the strength of materials, instruments, etc., can solve the problem of insufficient bending resistance detection of steel plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

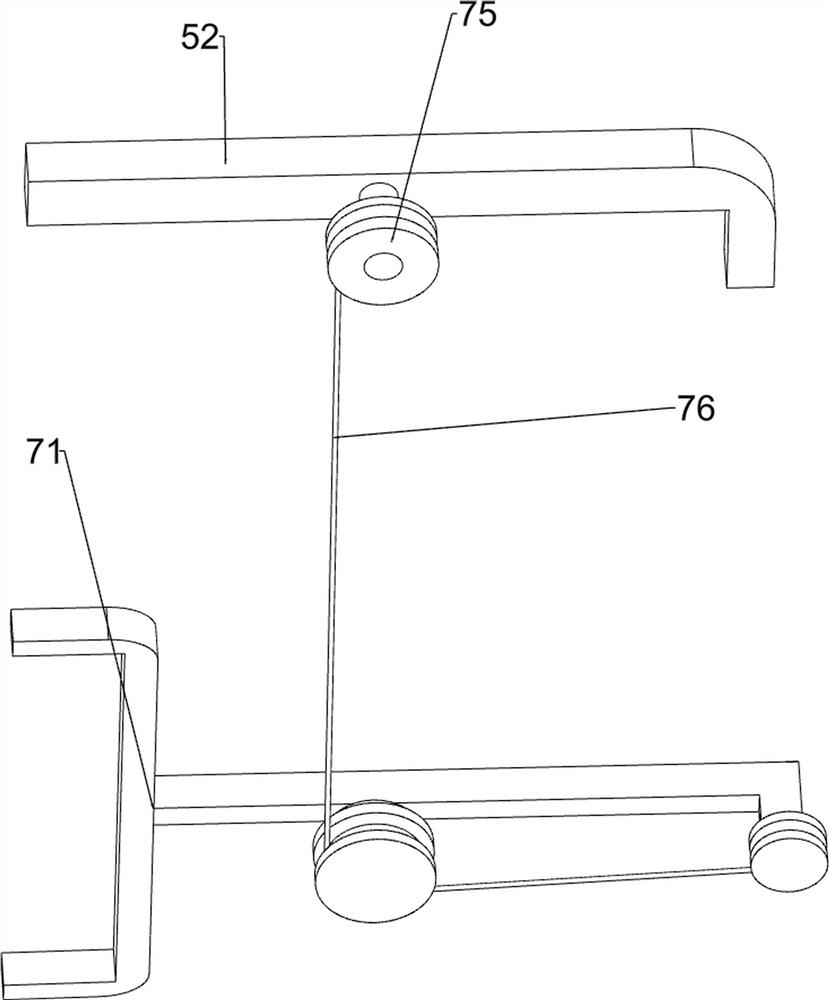

[0058] A bending resistance detection device for steel plates used in construction sites, such as figure 1 As shown, it includes a first fixing plate 1, a second fixing plate 2, a first fixing part 3, a bending mechanism 4 and a feeding mechanism 5. The first fixing plate 1 is provided with a second fixing plate 2, and the first fixing A first fixing part 3 is arranged on the left side of the plate 1, a bending mechanism 4 is arranged between the upper middle of the first fixing part 3 and the left side of the second fixing plate 2, and a feeding mechanism is arranged on the front side of the second fixing plate 2 5.

[0059] When people need to test the bending resistance of steel plates, this kind of steel plate bending detection device for construction sites can be used. First, people need to put the steel plate on the second fixed plate 2, and then push the feeding mechanism 5 to move backwards. After releasing the hand, the feeding mechanism 5 is automatically reset, and...

Embodiment 2

[0061] On the basis of Example 1, as figure 2 and image 3 As shown, the bending mechanism 4 includes a cylinder 41, a first sliding sleeve 42 and a pressing member 43, a cylinder 41 is installed in the middle of the upper side of the first fixing member 3, and the left part of the second fixing plate 2 is slidably installed on both sides. There is a first sliding sleeve 42 , a pressing part 43 is arranged between the first sliding sleeves 42 on both sides, and the telescopic rod of the air cylinder 41 is connected with the pressing part 43 .

[0062] When people push the steel plate under the pressing member 43, the cylinder 41 is activated, and the telescopic rod of the cylinder 41 drives the pressing member 43 to move downward, thereby driving the first sliding sleeve 42 to slide downward. When the pressing member 43 moves downwards , the steel plate can be subjected to a bending test. If the steel plate is bent, it means that the steel plate is not resistant to bending; ot...

Embodiment 3

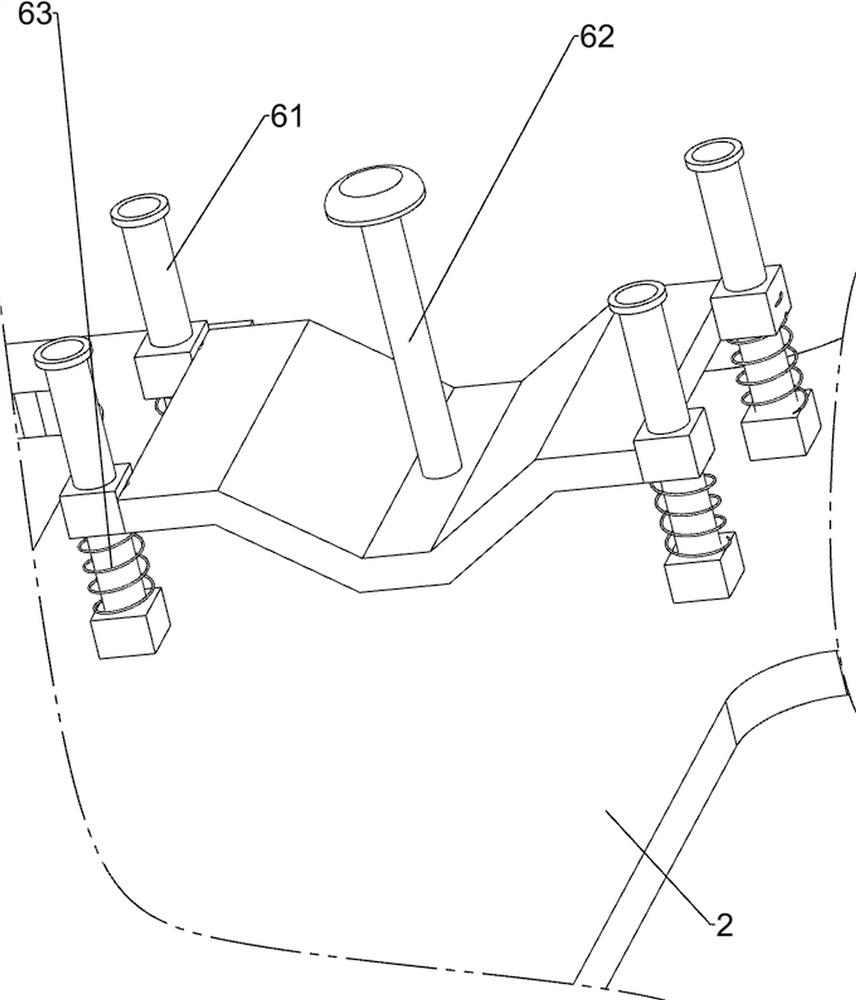

[0066] On the basis of Example 2, as Figure 4-Figure 8 As shown, it also includes a fixing mechanism 6. The fixing mechanism 6 includes a second rod 61, a pressure plate 62 and a second spring 63. The top left side of the second fixing plate 2 is evenly provided with four second rods 61. Four second rods 61. A pressure plate 62 is slidably arranged between the second rods 61 , a second spring 63 is wound around the lower side of the second rod 61 , and two ends of the second spring 63 are respectively connected to the pressure plate 62 and the second rod 61 .

[0067] When the steel plate is pushed under the pressure plate 62, people need to manually push the pressure plate 62 to slide down, the second spring 63 is compressed, and the downward movement of the pressure plate 62 can fix the steel plate and prevent the pressure member 43 from bending the steel plate during the test. The steel plate is displaced to achieve the effect of fixation. When the steel plate is tested, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com