Airplane control surface gap measuring device

A technology of measuring device and rudder surface, which can be used in aircraft component testing and other directions, which can solve the problems of inconvenient operation and high testing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

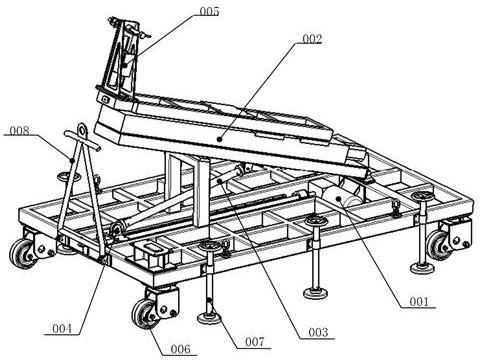

[0032] A kind of aircraft rudder surface gap measuring device of the present embodiment, such as figure 1 , Figure 4 , Figure 9 As shown, it includes a main body bracket and a turning part 002 arranged on the main body bracket. The connecting end of the turning part 002 is pivotally hinged with the top of the main body bracket. The driving end of the connecting rod 003 is slidingly connected to the top of the main body bracket, and the supporting end of the connecting rod 003 is hinged to the bottom of the turning part 002; The driving mechanism 001; on the side of the overturning part 002 away from the main body support, a sliding lift frame 026 is slid along the length direction of the overturning part 002, and a driving sliding frame 026 is provided between the sliding lifting frame 026 and the overturning part 002. The lifting frame 026 is a linear sliding module 024 that slides, and the force applying device 005 is detachably arranged on the sliding lifting frame or t...

Embodiment 2

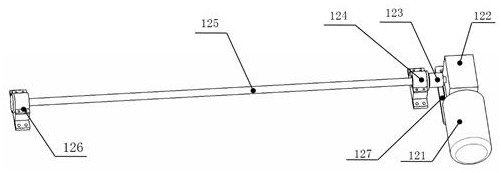

[0038] This embodiment is further optimized on the basis of embodiment 1, such as Figure 7 and Figure 8 As shown, the force applying device 005 includes a force applying device skeleton 051, a force applying linear movement mechanism, a ball joint 055, and a force sensor 056, and the force applying device skeleton 051 is arranged on the sliding lifting frame 026 or on the main body support , the end of the force applying device skeleton 051 away from the sliding lifting frame is provided with a force applying linear movement mechanism, the moving end of the force applying linear movement mechanism is connected to one end of the force sensor 056, and the other end of the force sensor 056 A ball joint 055 is provided.

[0039] The connecting end of the force applying device skeleton 051 is directly installed on one end of the sliding lifting frame 026 or on the top of the main body bracket through connecting bolts. It is directly connected with the ball and socket universal ...

Embodiment 3

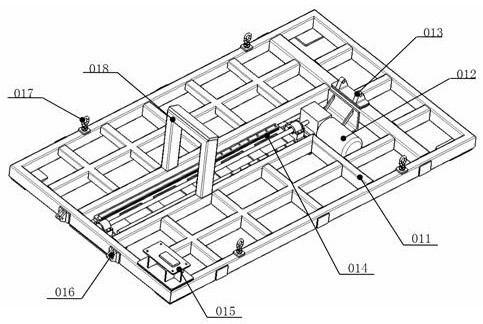

[0045] This embodiment is further optimized on the basis of above-mentioned embodiment 1 or 2, such as figure 2 As shown, the overturn driving mechanism 001 includes a linear guide rail 014, an overturn component mounting support 013 fixedly installed at one end of the linear guide rail 014, a sliding support 004 slidably arranged on the linear guide rail 014, and an overturning device that drives the sliding support 004 to slide. The linear drive mechanism 012, the connecting end of the turning part 002 is hinged on the top of the turning part mounting support 013, and the driving end of the connecting rod 003 is hinged on the top of the sliding support 004.

[0046] Such as figure 2 and Figure 6 As shown, the main body bracket includes a main body frame 011, the top of the main body frame 011 is provided with a mounting groove along the midline in the length direction, two linear guide rails 014 are arranged in parallel alignment in the mounting groove, and the bottom si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com