Cutting processing method for medical film preparation

A processing method and cutting technology, applied in the direction of metal processing, etc., can solve the problems of affecting the continuity of cutting operations, low work efficiency, accidental position deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

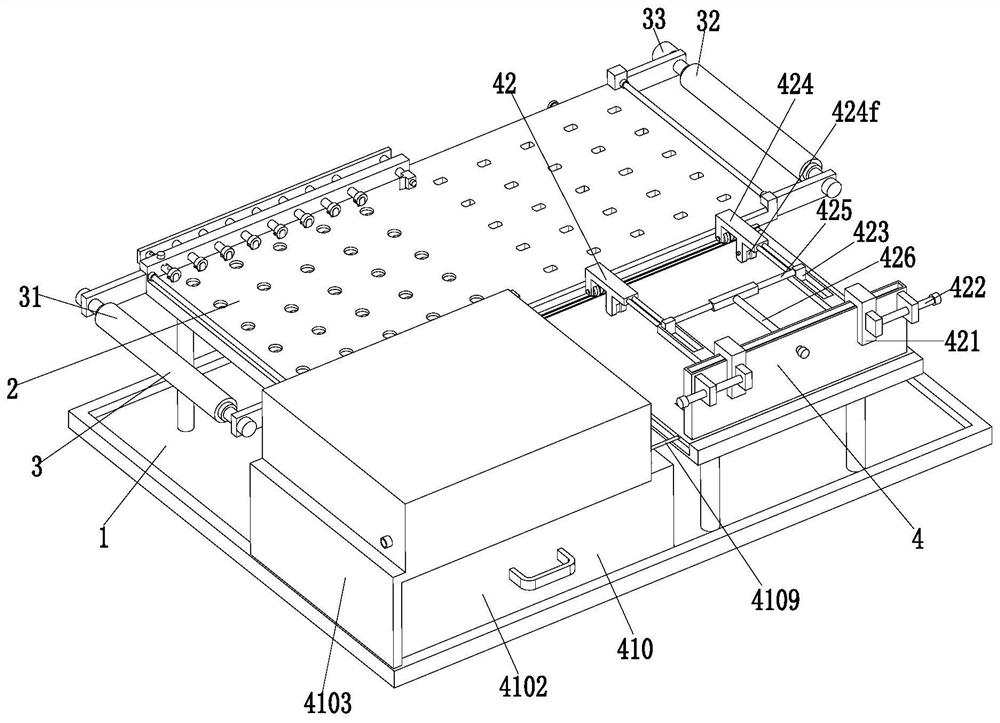

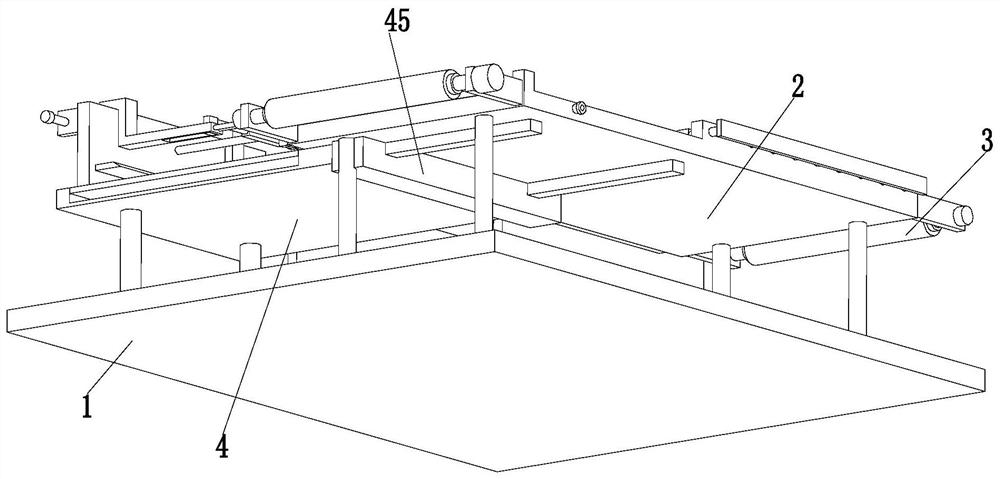

[0042] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

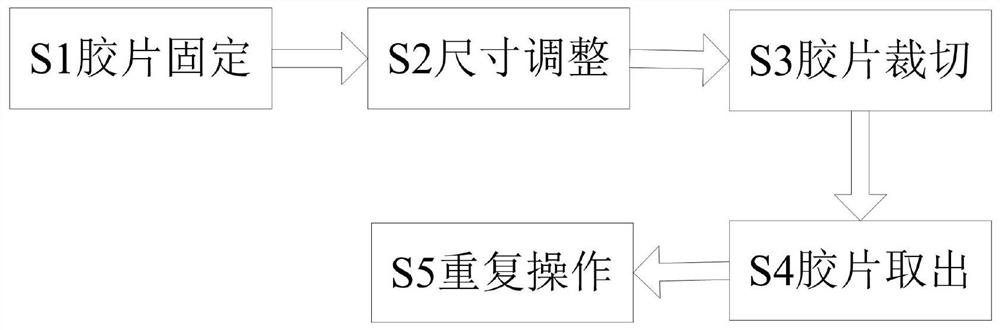

[0043] Such as Figure 1 to Figure 10 Shown, a kind of medical film preparation cutting processing method, it has used a kind of cutting machine, and this cutting machine comprises base plate 1, workbench 2, film fixing device 3 and cutting device 4, and above-mentioned cutting machine is used The specific method flow for the preparation and cutting of medical film is as follows:

[0044] S1 film fixation: the roll-shaped medical film is fixed at the specified position by the film fixation device 3;

[0045] S2 size adjustment: according to the specified size specification requirements, the corresponding parts of the cutting device 4 are adjusted in size;

[0046] S3 film cutting: After the size is determined, the medical film is cut horizontally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com