Two-end press-fit equipment for nut special for automobile fastener

A technology of pressing equipment and fasteners, which is applied in the field of auto parts processing and can solve problems such as slow work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

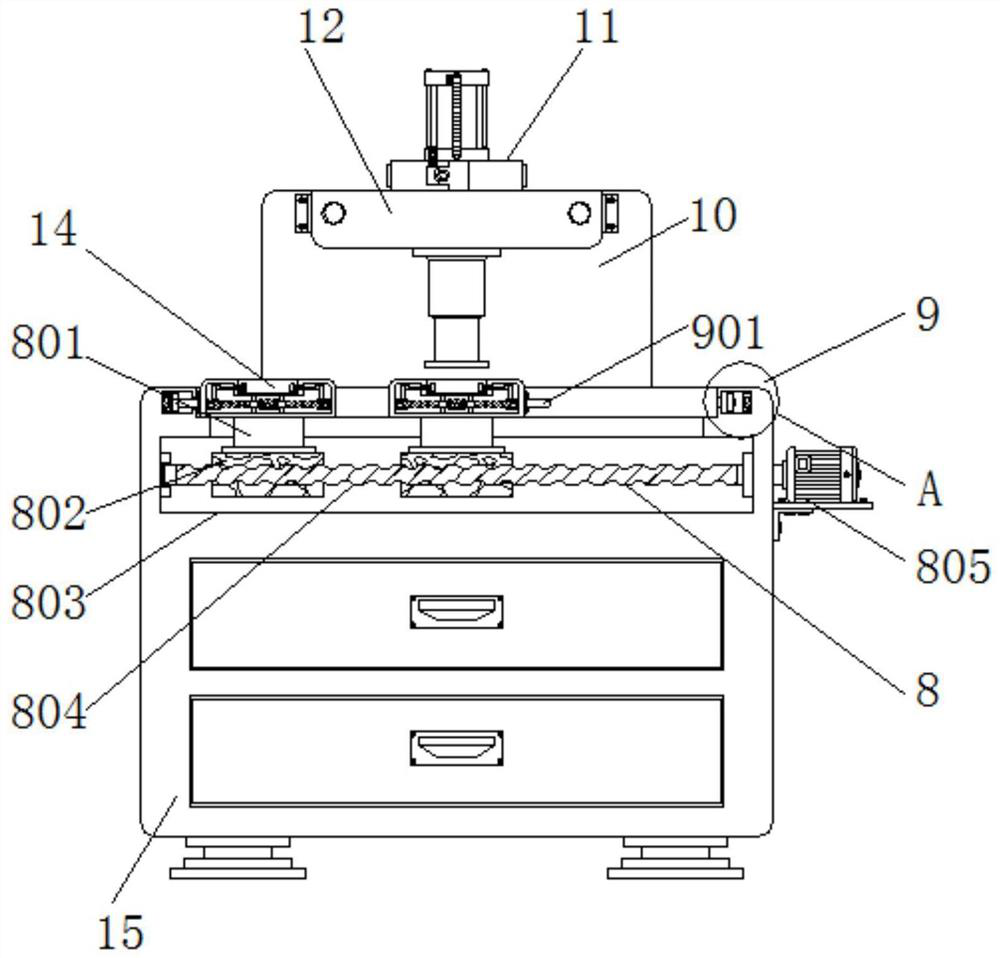

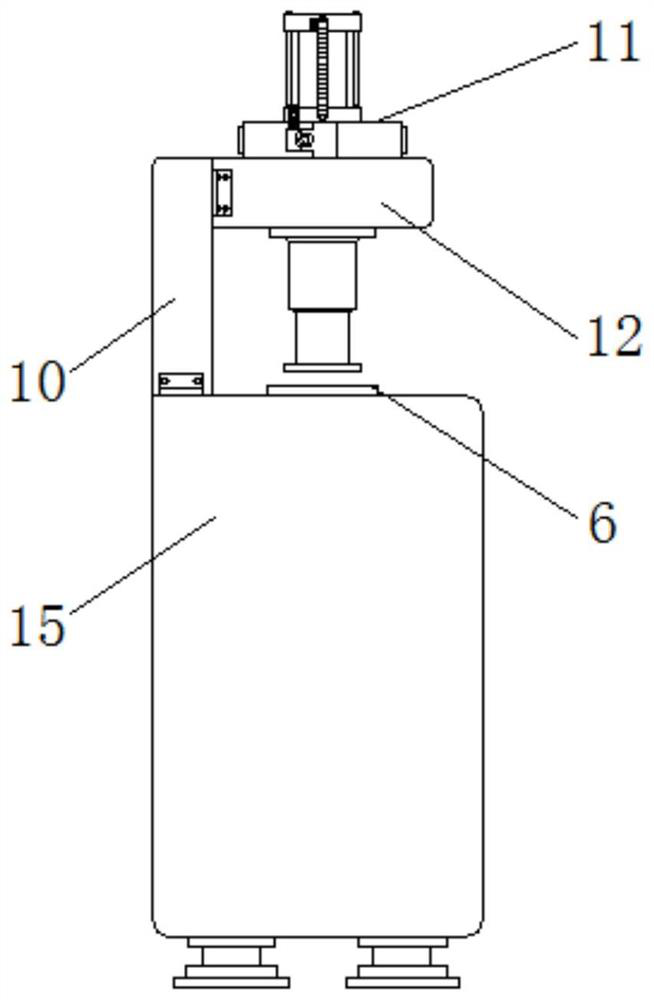

[0026] Example 1: See Figure 1-5 , a two-end pressing device for special nuts for automobile fasteners, including a main box 15, a moving structure 8 for accelerating work efficiency, a positioning structure 9 for precise processing, and a clamping structure for easy operation;

[0027] The top of the main box 15 is provided with a chute 17, and the inside of the chute 17 is slidably connected with two placement plates 6, one end of the top of the chute 17 is equipped with a vertical plate 10, and the top of one end of the vertical plate 10 is equipped with a top plate 12, A cylinder 11 is installed at the top center of the top plate 12, the model of the cylinder 11 can be SC63, and the bottom of the cylinder 11 penetrates to the bottom of the top plate 12, and the moving structure 8 is arranged inside the main box 15 below the chute 17;

[0028] Empty slots 14 are provided at the middle position of the top of the placement plate 6, and the positioning structure 9 is arranged...

Embodiment 2

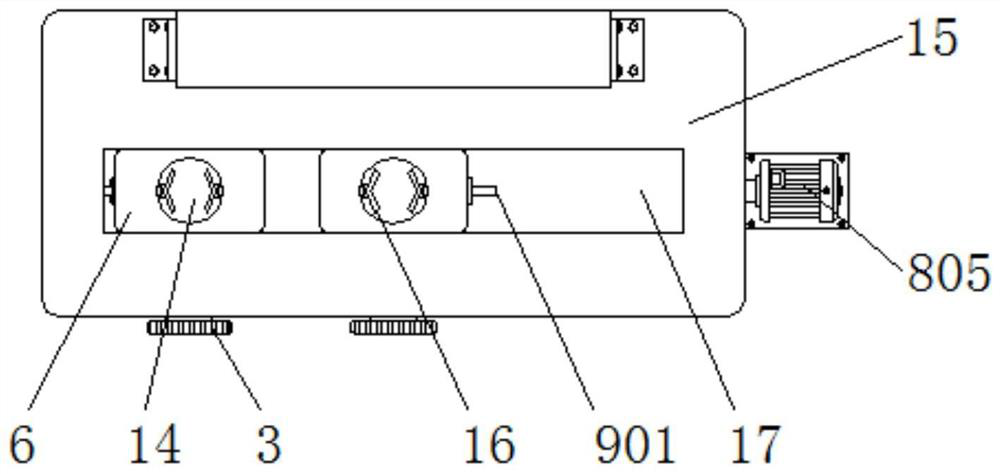

[0034] Embodiment 2: The moving structure 8 includes a connecting plate 801, a second sleeve 802, a cavity 803, a second screw mandrel 804 and a servo motor 805. The cavity 803 is set inside the main box 15 below the chute 17, and the servo motor 805 is installed on the top of one side of the main box 15, the model of the servo motor 805 can be RDX-201-V36F5E13, the output end of the servo motor 805 is connected with a second screw mandrel 804, and the second screw mandrel 804 inside the cavity 803 The outer wall is slidingly connected with two second sleeves 802, and the tops of the second sleeves 802 are connected with connecting plates 801, and the tops of the connecting plates 801 are connected with the placement plate 6;

[0035] One end of the second screw rod 804 runs through the inside of the cavity 803, and one end of the second screw rod 804 is connected to the inner wall of the cavity 803 through a rotating shaft;

[0036] Specifically, as figure 1 and image 3 As...

Embodiment 3

[0037] Embodiment 3: The positioning structure 9 includes a guide rod 901, an electric shock groove 902, a first magnet 903, a contact 904 and a second magnet 905. The guide rods 901 are all arranged on the side where the placement plate 6 is far away from each other, and the electric shock grooves 902 are Open inside the main box 15 on both sides of the chute 17, a first magnet 903 is provided on one side of the electric shock groove 902, and a second magnet 905 is slidably connected to the electric shock groove 902 on the first magnet 903 side, and the second A contact 904 is installed on the side of the magnet 905 close to the first magnet 903;

[0038] Specifically, as figure 1 , image 3 and Figure 5 As shown, when using this mechanism, while the placement plate 6 moves, the guide rod 901 moves, and the guide rod 901 is inserted into the electric contact slot 902, pushing the second magnet 905 and the contact 904 to slide toward the first magnet 903 at the same time unti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com