Thickener control system and method

A control method and control system technology, applied in the field of thickener control system, can solve the problems of difficult control of flocculant addition, overflow water cannot meet the standard, time-consuming and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of one or more embodiments. It may be evident, however, that these embodiments may be practiced without these specific details.

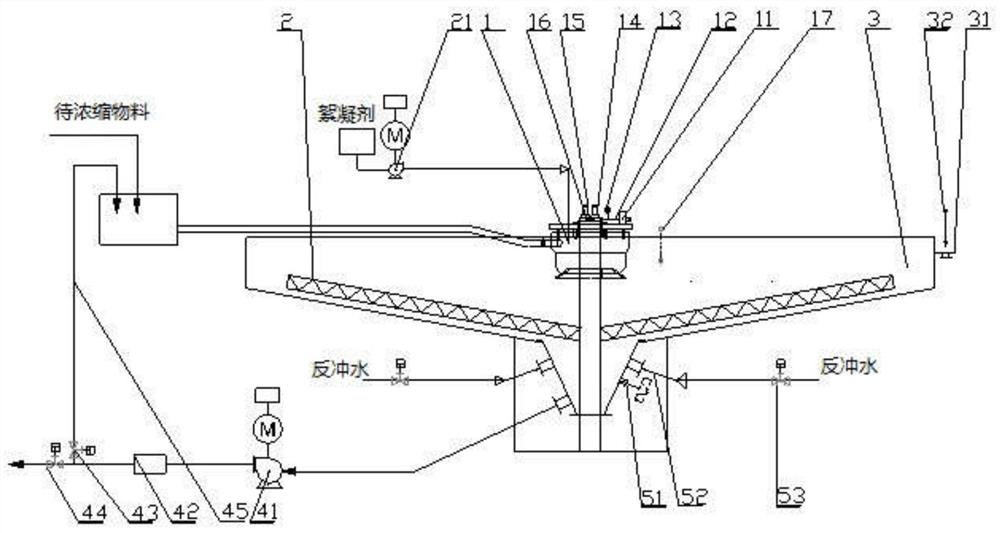

[0044] The thickener uses the material particles in the slurry to settle naturally under the action of its own gravity to complete the concentration, that is, after the slurry enters the thickening tank, the material particles in the slurry will gradually settle to the inclined cone relying on its own gravity. Shaped tank bottom, that is, the slurry concentration in the thickening tank will present four different concentration intervals from top to bottom: the clarification zone, the settlement zone, the transition zone and the compression zone; among them, the high-concentration product settled in the compression zone is passed through rotation The rakes on the rake frame are gradually raked to the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com