Non-contact thermal wave heater

A heater, non-contact technology, applied in the direction of tobacco, etc., can solve problems such as affecting the user's experience, uneven heating, and difficulty in cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to describe the technical solution of the present invention more clearly and completely, the present invention will be further described below in conjunction with the accompanying drawings.

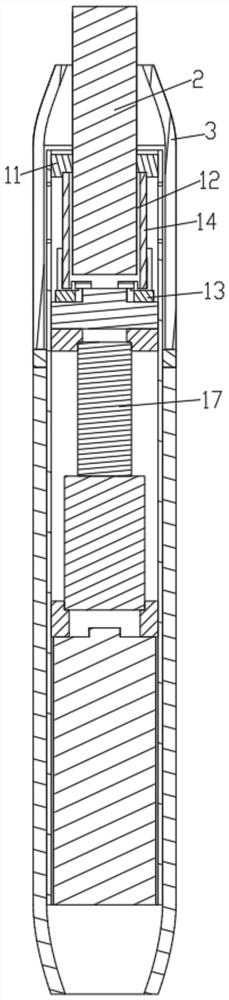

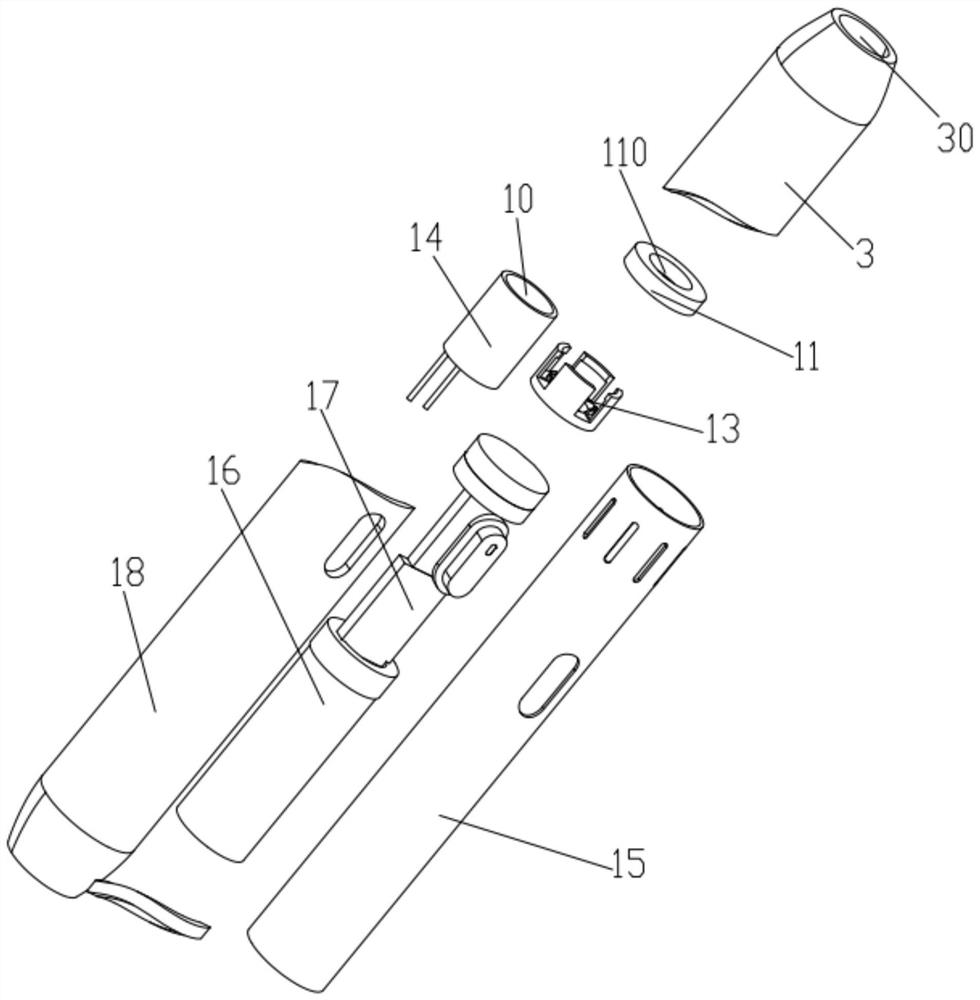

[0026] Please refer to Figure 1-Figure 4 , the present invention proposes a non-contact thermal wave heater, comprising a host 1 and a cover body 3 movable to cover the host 1, the host 1 is provided with a heating chamber 10, a clamping part 11, and the clamping part 11 can clamp the cartridge 2 so that the cartridge 2 protrudes into the heating chamber 10 to heat the cartridge 2, and when the cartridge 2 extends into the heating chamber 10, the cartridge 2 The cartridge 2 is not in contact with the inner wall of the heating chamber 10 so that an air passage 12 is formed between the cartridge 2 and the inner wall of the heating chamber 10 .

[0027] In this embodiment, the middle part of the pod 2 is clamped by the clamping member 11, one end of the pod 2 protrudes into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com