Projectile shell separation structure

A technology for separating structures and rocket shells, which is applied in the field of spacecraft structures, can solve problems such as large separation and separation distances, easy interference problems, and complex separation structures, so as to reduce separation links, prevent interference between structures, and simple separation structures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

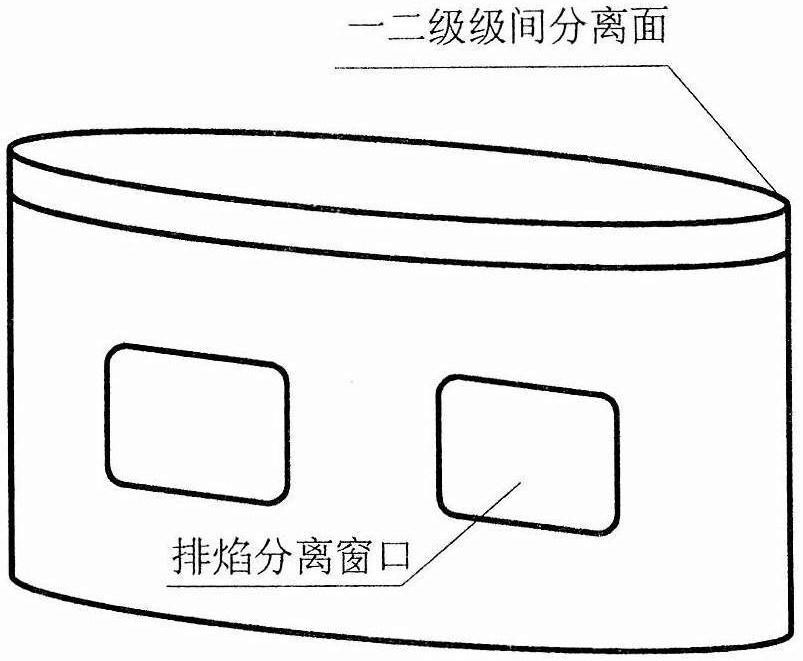

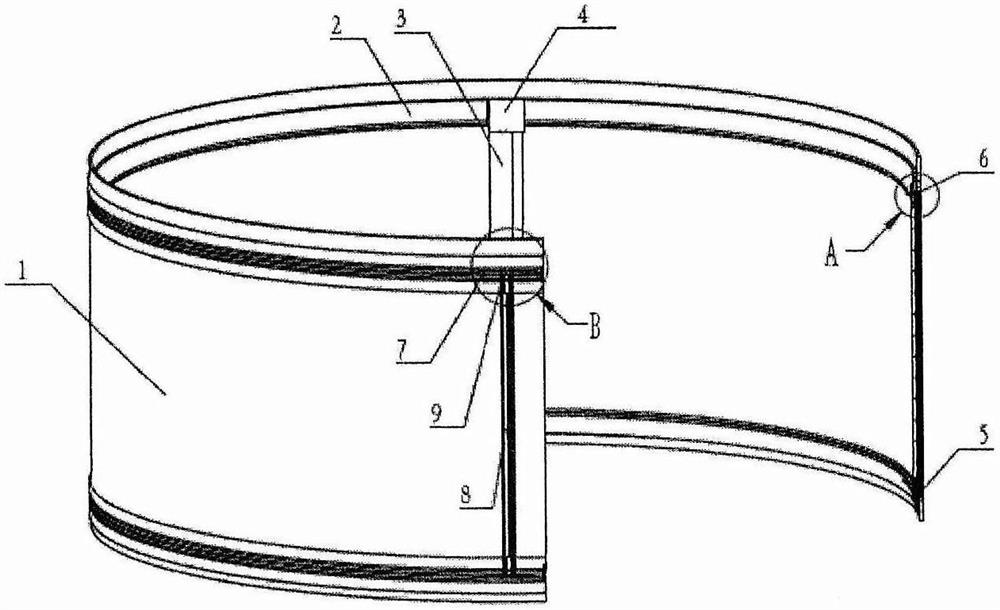

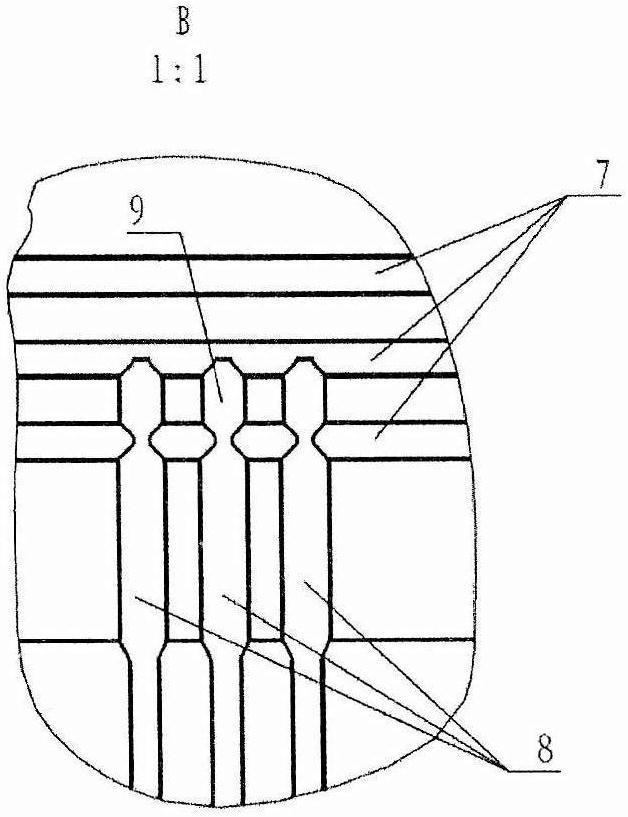

[0020] The separation structure of the rocket shell of the present invention is an annular closed structure, such as figure 2 Shown is a partial cross-sectional schematic view of the cutting and separating structure of the present invention. The separation structure of the missile case includes: a separation case 1 , a circumferential shield 2 , an axial shield 3 , a T-shaped shield 4 , a flexible detonating cord assembly 5 and a T-shaped explosion transfer assembly 6 . At the predetermined separation place outside the circumference of the separation shell 1, there are respectively circumferential preset weakening grooves 7, axial preset weakening grooves 8 and T-shaped prefabricated weakening grooves 9, as attached image 3 shown.

[0021] On the upper and lower end faces of the separation case 1 , the flexible detonating cord assembly 5 is installed in the position cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com