Method for evaluating welding heat resistance of plastic package component

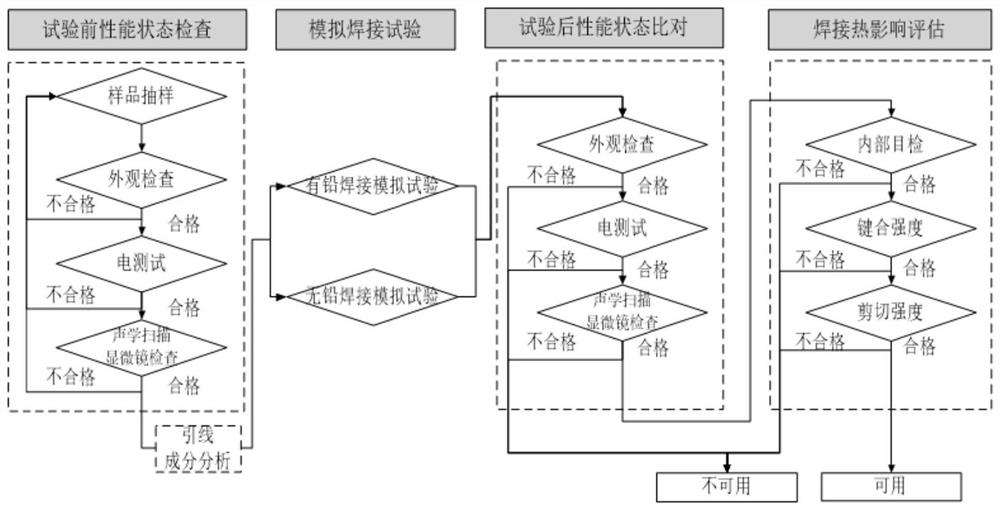

A technology of soldering heat resistance and evaluation method, which is applied in the direction of instruments, optical testing flaws/defects, measuring devices, etc., and can solve problems such as soldering heat resistance, failure, and reduced reliability of components that are difficult to plastic seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

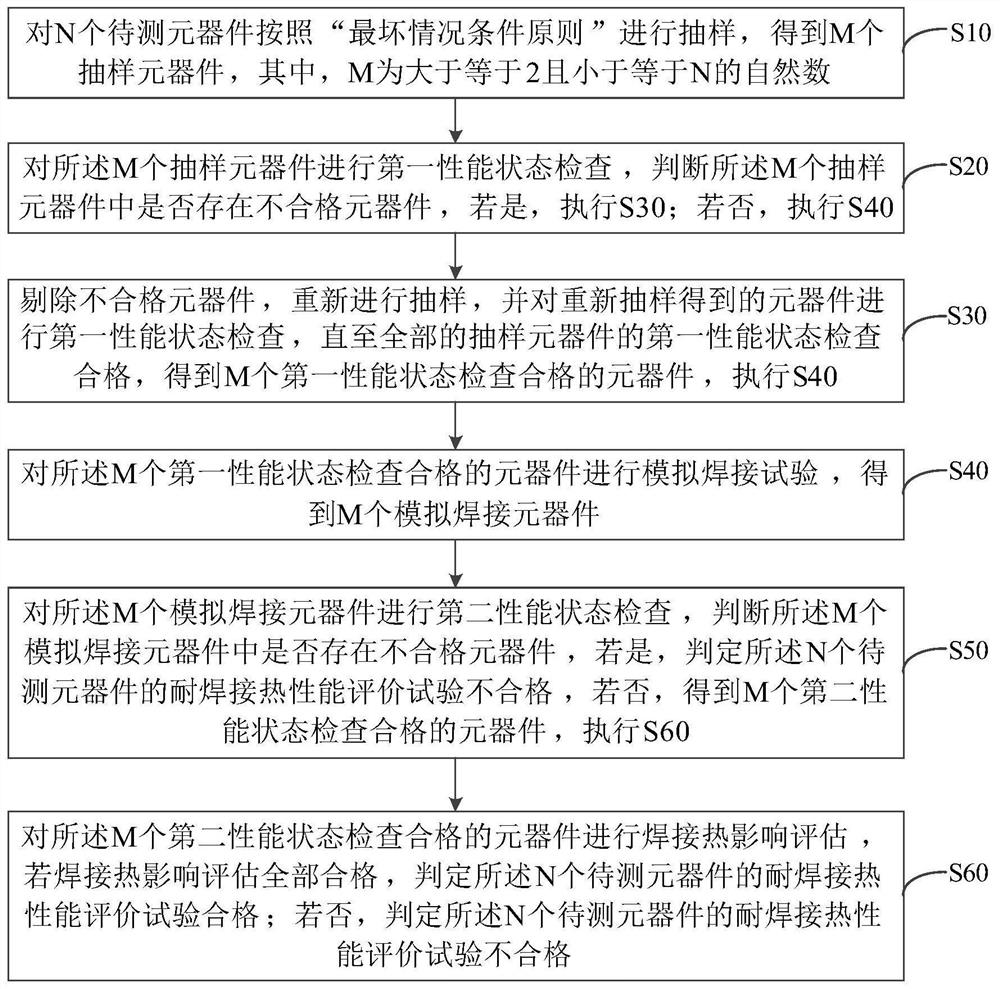

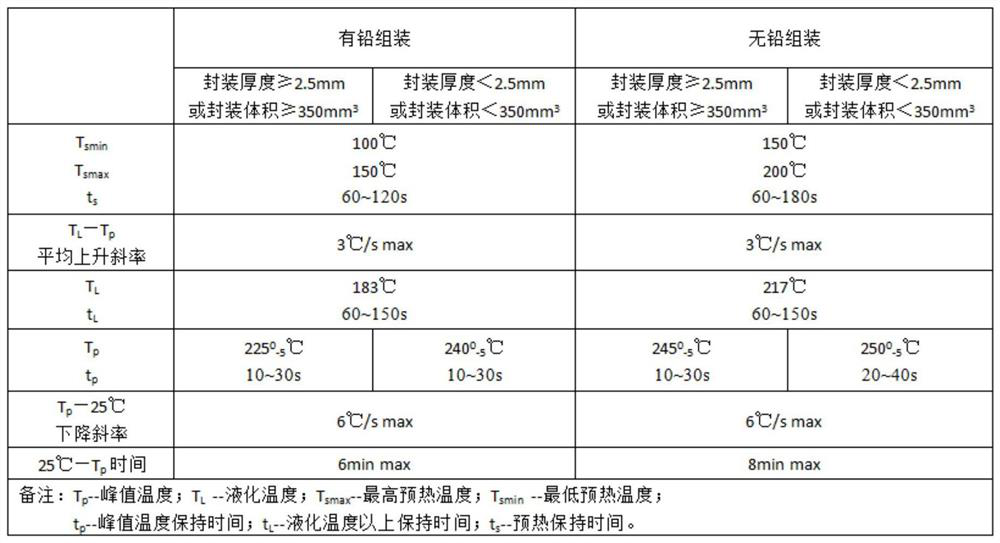

Method used

Image

Examples

Embodiment Construction

[0042] In order to illustrate the present application more clearly, the present application will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present application.

[0043]Electronic components are the core and foundation of equipment, and their quality directly affects the reliability of the equipment system. Plastic-encapsulated devices are highly reliable and expensive, and are generally used in military high-reliability fields. With the increasing demand for miniaturization and high integration of plastic-encapsulated devices, the size of plastic-encapsulated devices is getting smaller and smaller, and the leads are getting denser. During the assembly process of components, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com