Automatic carrier feeding device

An automatic feeding and driving connection technology, applied in the direction of conveyor control devices, transportation and packaging, conveyor objects, etc., can solve the problems of carrier placement, low work efficiency, errors, etc., to improve conveying accuracy, reduce manpower, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

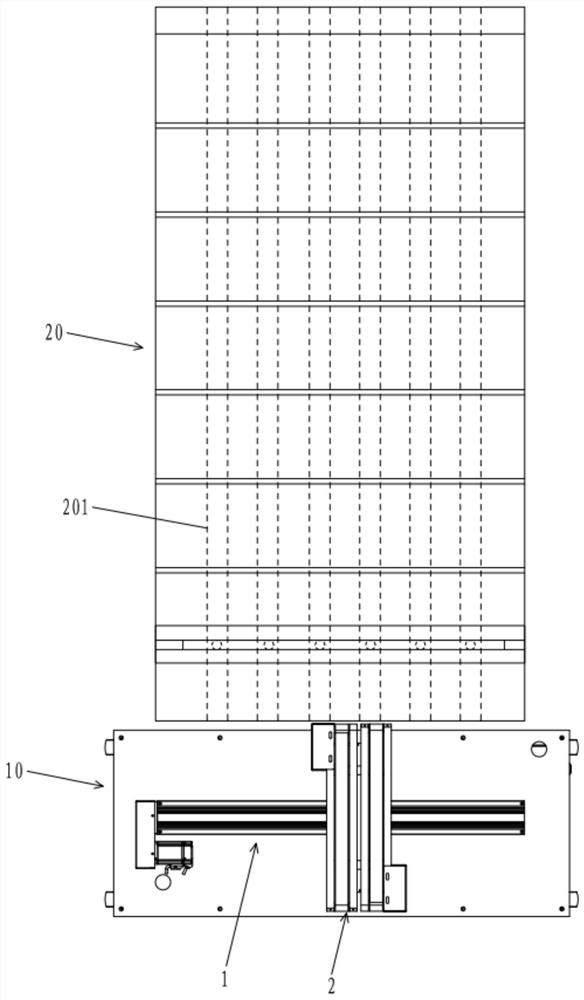

[0034] refer to Figure 1 to Figure 6 , a carrier automatic feeding device 10, the feeding device 10 is applied to the oven production line 20, the oven production line 20 is provided with a plurality of runners 201, the feeding device 10 includes an X-axis conveying mechanism 1 and a receiving flow channel Agency 2;

[0035] The X-axis conveying mechanism 1 is driven and connected with the receiving channel mechanism 2;

[0036] The channel receiving mechanism 2 can transport the carrier to any branch channel 201 .

[0037] To further illustrate, there are multiple receiving flow channel mechanisms 2, and each receiving flow channel mechanism 2 can operate independently.

[0038] To further illustrate, the receiving channel mechanism 2 includes a conveyor belt 22 and a second motor 21 , and the conveyor belt 22 and the second motor 21 are drivingly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com