Tea frying device capable of assisting in discharging

A technology that assists in cutting and frying tea. It is applied in tea processing before extraction, etc. It can solve the problems of light and severe breakage or overheating, and the tea type is not very good, and achieves the effect of simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

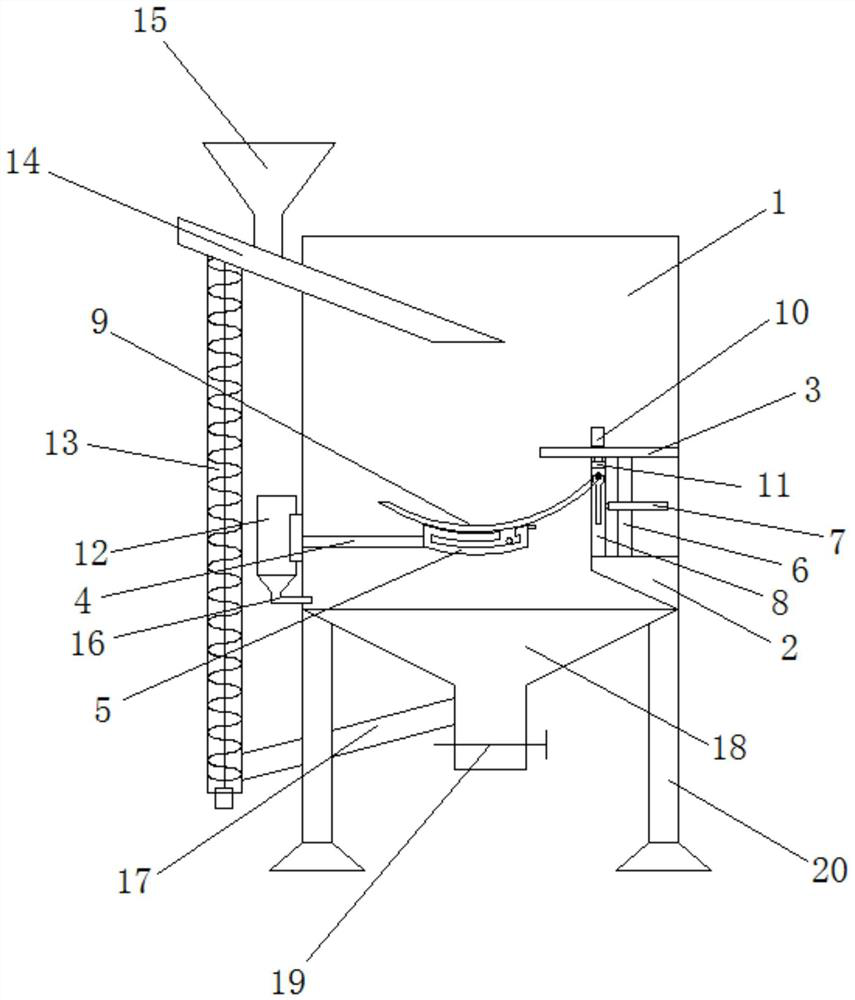

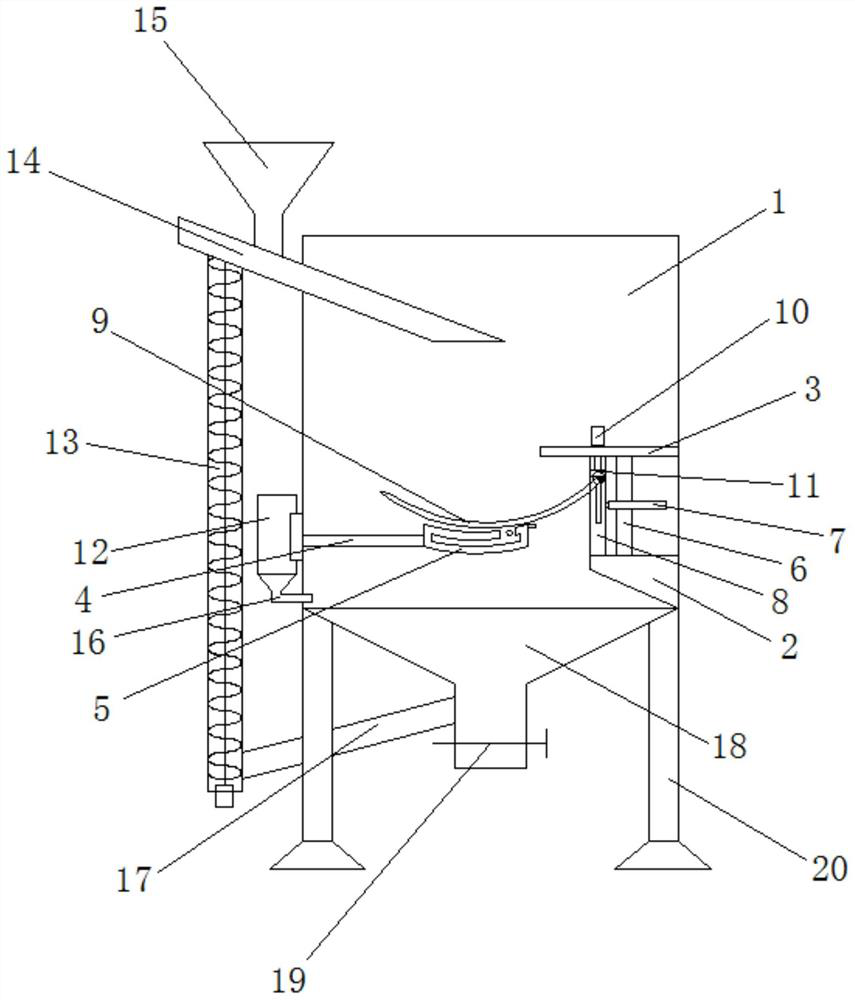

[0038] Embodiment 1: as Figure 1-10 As shown, a tea frying device for auxiliary feeding includes a working chamber 1, the lower right side of the inner chamber of the working chamber 1 is fixedly connected with an abutment 2, and the right middle part of the inner chamber of the working chamber 1 is fixedly connected with a A beam frame 3, a vertical frame 6 is fixedly connected between the abutment 2 and the beam frame 3, two groups of first telescopic frames 7 are horizontally installed on the vertical frame 6, and two groups of first telescopic frames 7 The left end of the left end is fixedly connected with an adjustment frame 8, and the top side of the adjustment frame 8 is flexibly connected with the beam frame 3, and each group of the adjustment frame 8 is provided with a strip groove 801;

[0039] The lower left side of the inner cavity of the working warehouse 1 is fixedly connected with a mounting frame 4, the right end of the mounting frame 4 is fixedly connected wi...

Embodiment 2

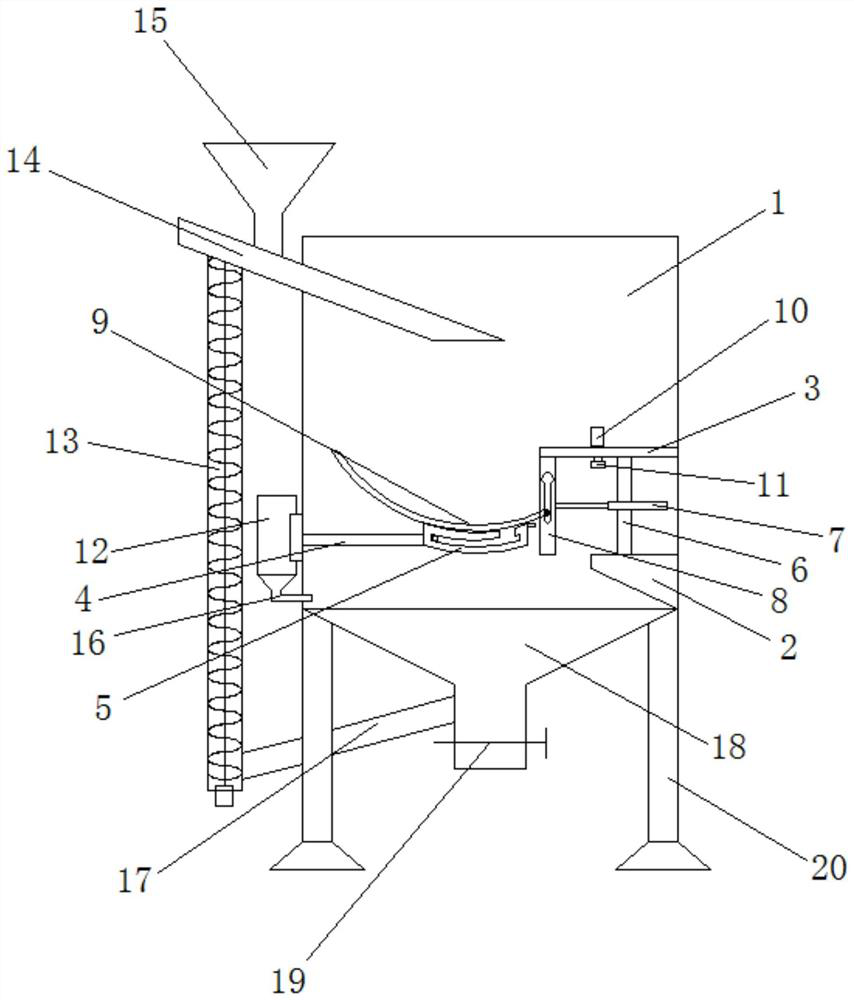

[0053] Embodiment 2: as Figure 1-10 As shown, a tea frying device for auxiliary feeding includes a working chamber 1, the lower right side of the inner chamber of the working chamber 1 is fixedly connected with an abutment 2, and the right middle part of the inner chamber of the working chamber 1 is fixedly connected with a A beam frame 3, a vertical frame 6 is fixedly connected between the abutment 2 and the beam frame 3, two groups of first telescopic frames 7 are horizontally installed on the vertical frame 6, and two groups of first telescopic frames 7 The left end of the left end is fixedly connected with an adjustment frame 8, and the top side of the adjustment frame 8 is flexibly connected with the beam frame 3, and each group of the adjustment frame 8 is provided with a strip groove 801;

[0054] The lower left side of the inner cavity of the working warehouse 1 is fixedly connected with a mounting frame 4, the right end of the mounting frame 4 is fixedly connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com