A Fatigue Analysis Method for Boom

A fatigue analysis and boom technology, applied in the field of stress analysis, can solve problems such as spending a lot of time in inspection and calibration, regional and size deviation, and difficulty in obtaining, so as to improve the accuracy of fatigue analysis, reduce the difficulty of calculation, and simplify the calculation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further described below in conjunction with embodiments and accompanying drawings, but embodiments of the present invention are not limited thereto.

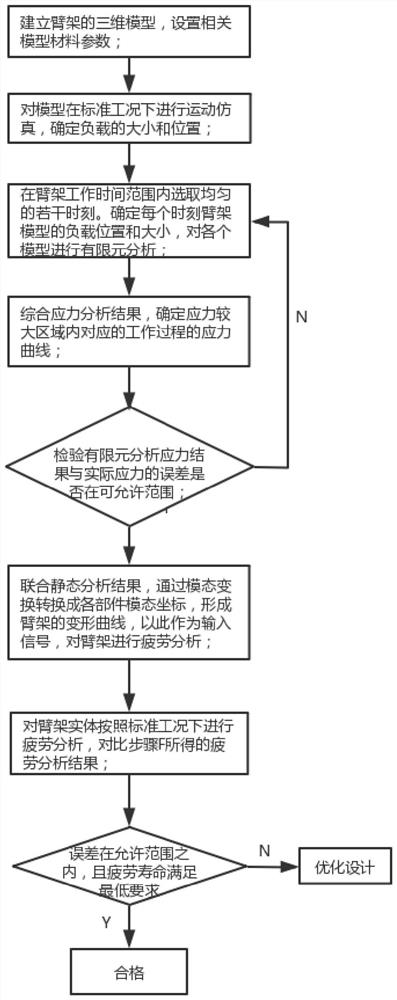

[0027] SeeFigure 1 , the present embodiment of the boom fatigue analysis method, comprising the following steps:

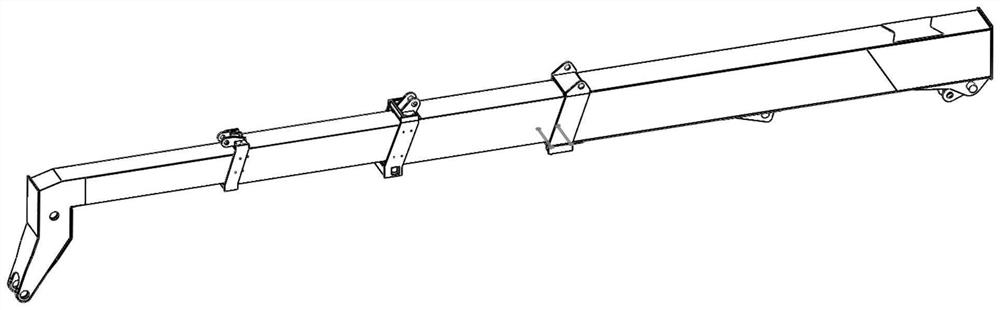

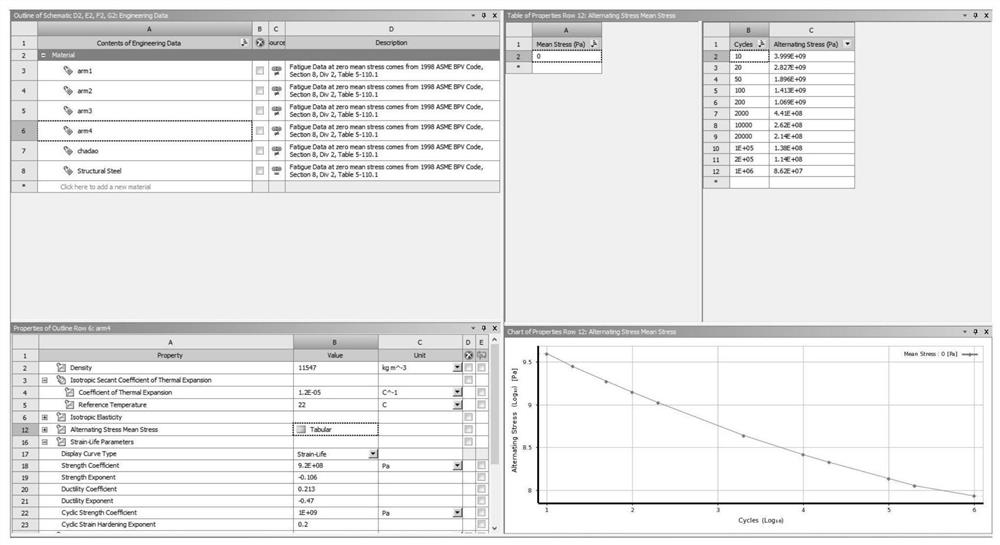

[0028] (1) Establish a three-dimensional model according to the actual shape and size of the arm, establish a network model of the arm by the finite element method, and set the arm parameters. The boom parameters include material properties, density and modulus of elasticity. Specifically, it also includes yield stress, minimum tensile strength, Poisson's ratio and the like.

[0029] (2) The simulation software is used to simulate the movement of the arm under normal working conditions, and the motion data of the arm is subjected to change with time in a cyclic movement, including the load size and position; through the discretization of the motion data of the arm, a series of relatively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com