Industrial double-acting air cylinder

A double-acting cylinder, industrial technology, applied in the direction of fluid pressure actuating devices, etc., can solve the problems of wear of elastic components, cumbersome adjustment and calibration, shortening the service life of cylinders, etc., to achieve no wear of parts, improve stability, and prolong use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

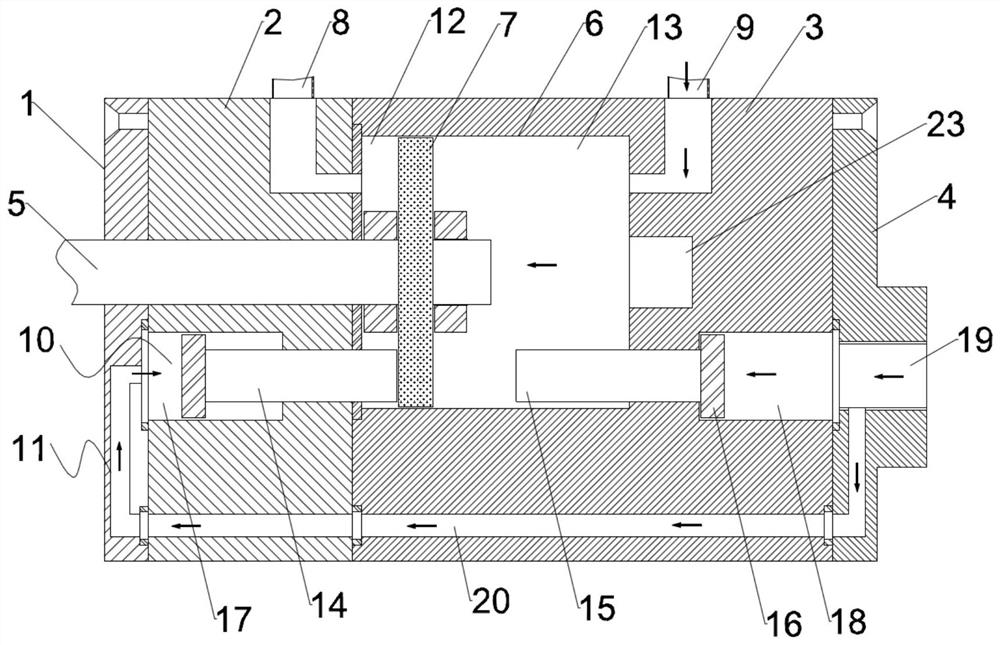

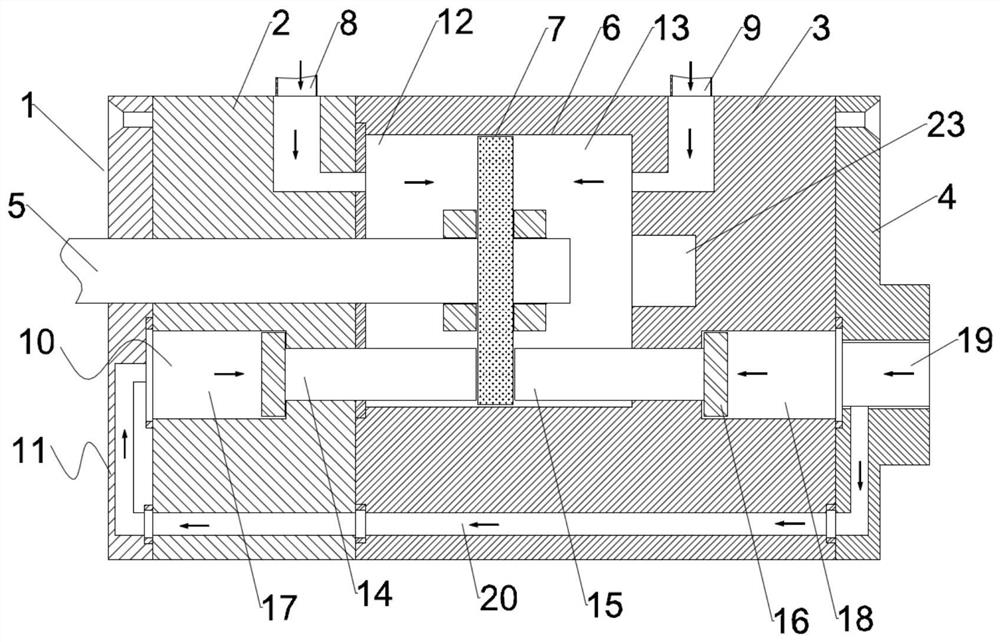

[0020] Such as Figure 1 to 3 As shown, an industrial double-acting cylinder includes a front cylinder head 1, a connecting barrel 2, a cylinder 3, a rear cylinder cover 4, and a piston rod 5, and the front cylinder head 1 is mounted at the front end of the connection cartridge 2, the connection The cartridge 2 and the rear cylinder cover 4 are respectively mounted on both ends of the cylinder 3, and the cylinder 3 is provided with a chamber 6, and the piston rod 5 extends to the chamber 6, and the other end passes through the connecting barrel 2 and The front cylinder head 1, the chamber 6 is provided with a piston 7 in the inner wall thereof, and the piston 7 is attached to one end of the piston rod 5, and the connecting barrel 2 and the cylinder bar are respectively provided. 8 and the air port 4 and it is connected to the chamber 6, and the cylinder also has a stability when the piston 7 is moved, and the auxiliary component 10 that can assist the piston 7 is quickly reset to t...

Embodiment 2

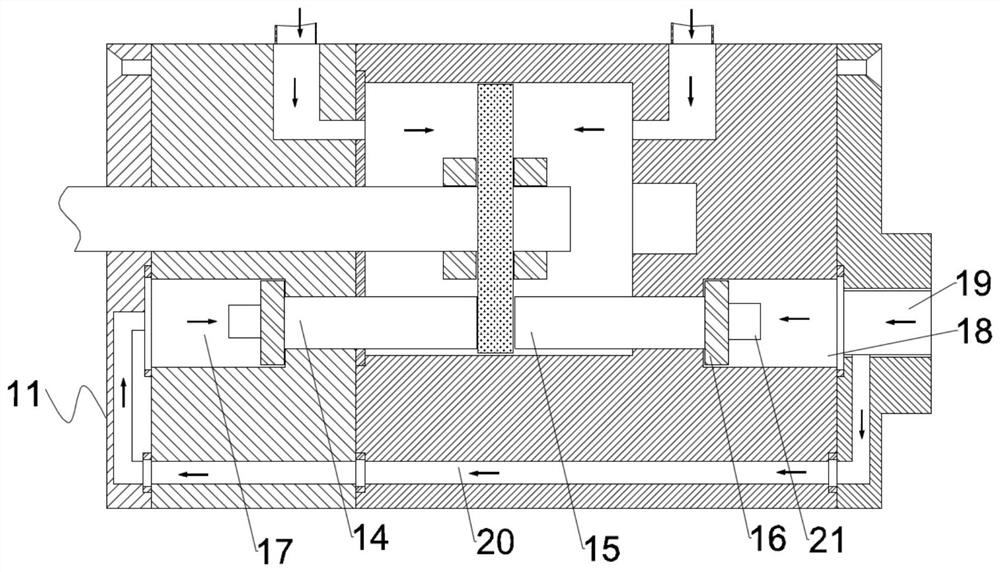

[0027] Such as Figure 4 As shown, in relation to the first embodiment, the adjusted block 21 is not mounted in the end portion of the auxiliary piston 16, but is a threaded hole in the end portion of the auxiliary piston, and the screw 22 is threaded in the threaded hole.

[0028] Inlet 1 8, the intake port 2 9 and the intake port 3 19 are connected to the compressed air source, and the intake port three 19 has been connected to the compressed air source.

[0029] Working process and principle: By transporting the compressed air by an intake port 2 9, the piston 7 can be slid in the chamber 6, and it is now assumed that the intake port 2 9 intake to the chamber 2 13, The piston 7 slides to the left limit position in the chamber 6 (eg figure 1 As shown in, the intake port 3 19 feeds the compressed air into the chamber B18 and the gas line 20, and the compressed air is supplied into the chamber A17 via the gas line 20, so that the two auxiliary piston 16 give the piston rod A14, res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com