Butt joint device for achieving staggered layer folding of adjacent arch frames and arch frame splicing method

A docking device and staggered-layer technology, which is applied in the field of docking devices to realize the staggered folding of adjacent arches, can solve problems such as waste, increased labor intensity of workers, and increased erection costs, and achieves easy transportation, easy disassembly, reusability, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

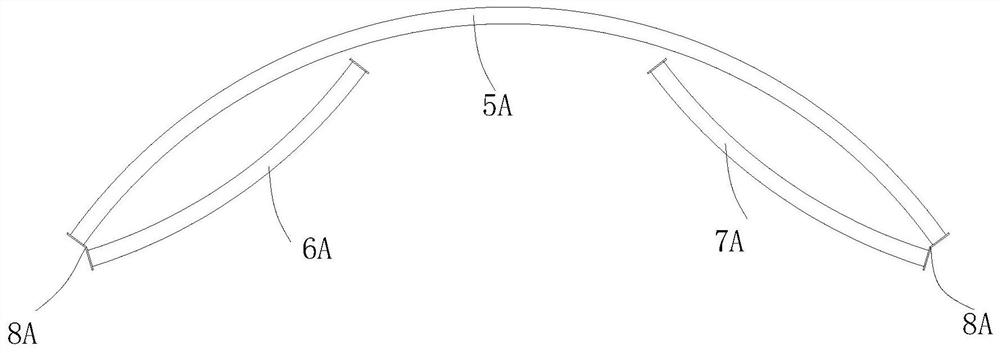

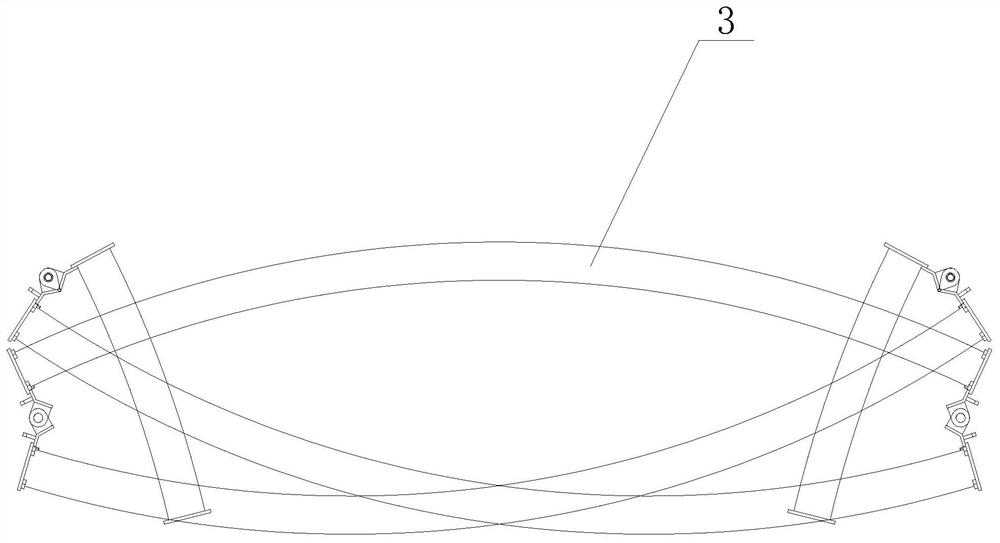

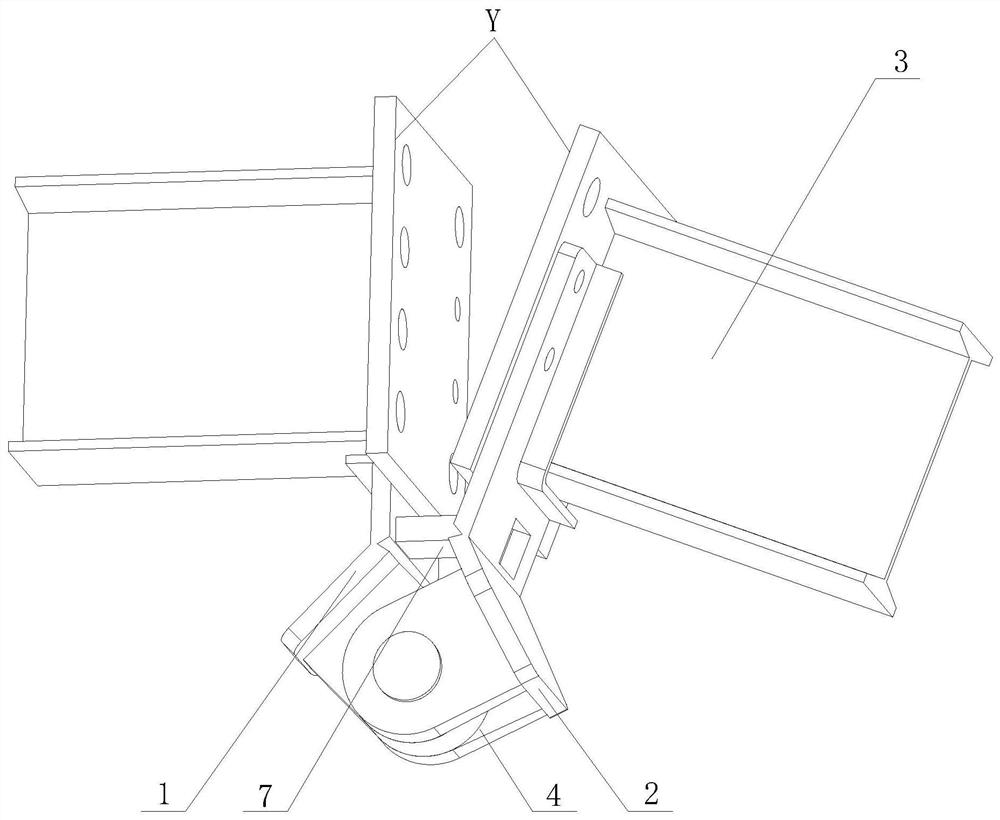

[0043] Such as Figure 2 to Figure 5 As shown in the present embodiment, a docking device for realizing staggered folding of adjacent arches includes a first connecting seat 1 and a second connecting seat 2, and the first connecting seat 1 and the second connecting seat 2 respectively connect adjacent Two arches 3, the first connection seat 1 and the second connection seat 2 form a mutual rotation connection that can make the adjacent two arches 3 in a folded state or a docking state. When folding and rotating, the first connection seat There is a gap 4 between the 1 and the second connecting seat 2 that can deviate itself from the rotation plane to drive the adjacent arches 3 to be folded; The rotational cooperation of the two drives the two to eliminate the deflection to drive the adjacent arches 3 to align. Such as figure 1As shown, the existing arch folding can only fold the two lower arches to the inner side of the upper arch section. This folding method actually takes ...

Embodiment 2

[0052] Such as Figure 6 As shown, the second embodiment of the docking device of the present invention that realizes the staggered folding of adjacent arches, the docking device is basically the same as the docking device of Example 1, the only difference is that: a second gap 42 is provided to facilitate the first The connecting seat 1 and the second connecting seat 2 are deflected and the auxiliary mechanism 6 that prevents them from being displaced in the radial direction of the hinge column 5 is specially set or / and the guide correction piece 7 can not only eliminate the deflection effect caused by the first gap 41, but also eliminate the deflection effect caused by the second gap 42, so as to accurately ensure the passage of the butt bolts when two adjacent arches are docked coaxial.

[0053] In this embodiment, the auxiliary mechanism 6 includes a universal ball head shell 61 , the universal ball head shell 61 is sleeved on the hinge column 5 , and the first ear plat...

Embodiment 3

[0056] Such as Figure 7 As shown, the third embodiment of the docking device of the present invention that realizes the staggered folding of adjacent arches, the docking device is basically the same as the docking device of Example 1, the only difference is that: a second gap 42 is provided to facilitate the first The auxiliary mechanism 6 that deflects the connecting seat 1 and the second connecting seat 2 and prevents them from being displaced in the radial direction of the hinge column 5, the auxiliary mechanism 6 is special in combination with the sides of the first ear plate 12 and the second ear plate 22 Setting or / and the guide correction member 7 can not only eliminate the deflection effect caused by the first gap 41, but also eliminate the deflection effect caused by the second gap 42, so as to accurately ensure the butt joint bolts when two adjacent arches are docked Via coaxial.

[0057] In this embodiment, the auxiliary mechanism 6 is a universal ball joint beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com