Resin-based composite material mixing preparation device

A technology for composite materials and preparation devices, which is applied to mixers, mixers with rotating containers, transportation and packaging, etc. It can solve the problems of ineffective mixing of raw materials, insufficient and uniform mixing, and low efficiency, so as to shorten the mixing time, Improve mixing efficiency and avoid accumulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

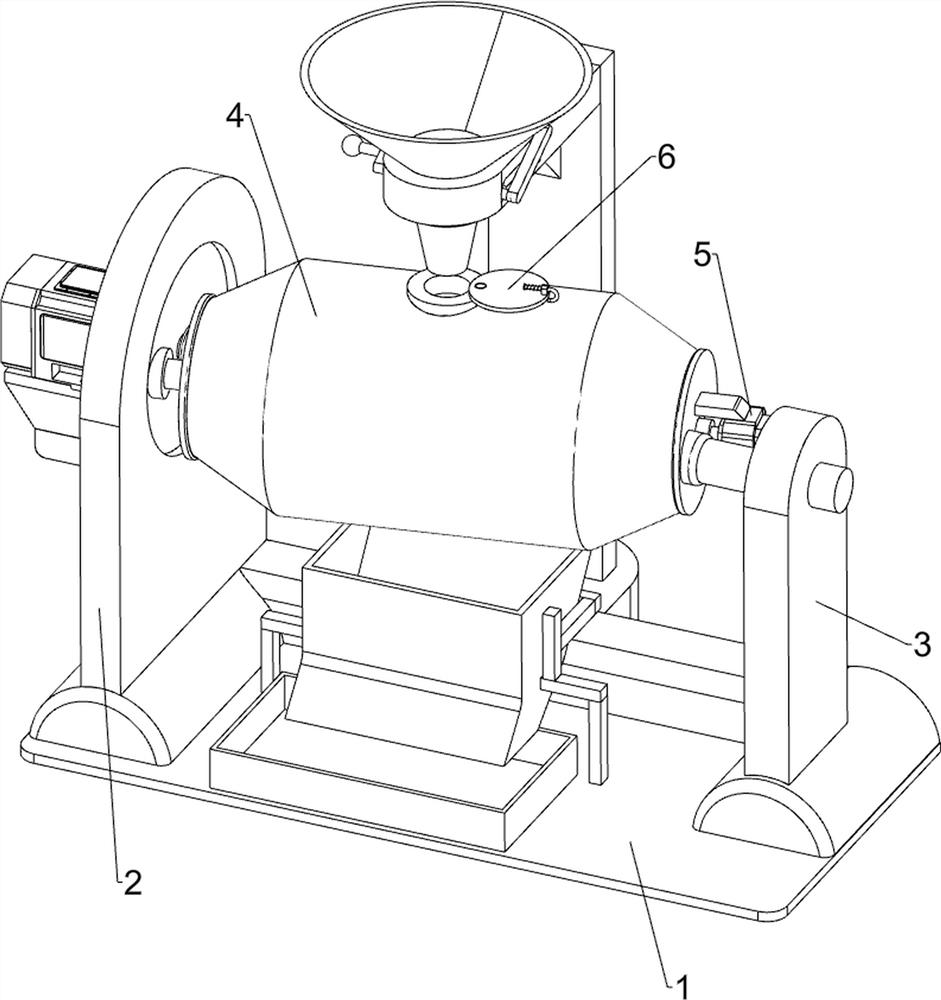

[0028] Such as figure 1 As shown, a resin-based composite material mixing and preparation device includes a bottom plate 1, a first bearing seat 2, a second bearing seat 3, a rotating mechanism 4, a stirring mechanism 5, and a feeding and discharging mechanism 6. The left side of the bottom plate 1 is provided with a second A bearing seat 2, a second bearing seat 3 is provided on the right side of the bottom plate 1, a rotating mechanism 4 is provided between the first bearing seat 2 and the second bearing seat 3, a stirring mechanism 5 is provided on the inner side of the middle part of the rotating mechanism 4, and the rotating mechanism 4 A feeding and discharging mechanism 6 is arranged outside the middle part.

[0029] A mixing and preparation device for resin-based composite materials. Firstly, resin-based materials and inorganic fillers are injected into the cylindrical container through the opening and closing of the feeding and discharging mechanism 6, and then the ra...

Embodiment 2

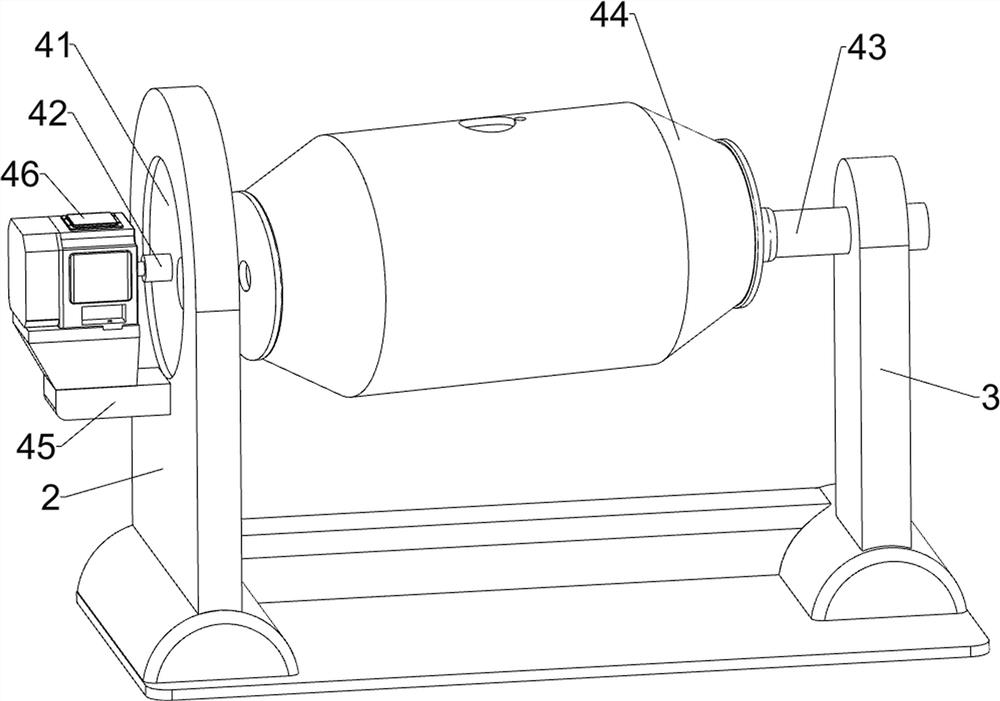

[0031] Such as figure 2 , image 3 and Figure 4 As shown, on the basis of Embodiment 1, the rotating mechanism 4 includes a wheel 41, a first rotating shaft 42, a second rotating shaft 43, a conical cylinder 44, a first fixed block 45 and a first servo motor 46, the second A wheel 41 is rotatably arranged in the middle of the upper part of a bearing seat 2, and a first rotating shaft 42 is arranged at the center of the wheel 41, and a second rotating shaft 43 is rotatably arranged on the second bearing seat 3, and the first rotating shaft 42 and the second rotating shaft 43 An inclined conical cylinder 44 is connected between them, a first fixed block 45 is arranged in the middle of the left side of the first bearing seat 2, a first servo motor 46 is arranged on the top of the first fixed block 45, and the output shaft of the first servo motor 46 It is connected with the first rotating shaft 42 through a coupling.

[0032] The stirring mechanism 5 includes a third rotatin...

Embodiment 3

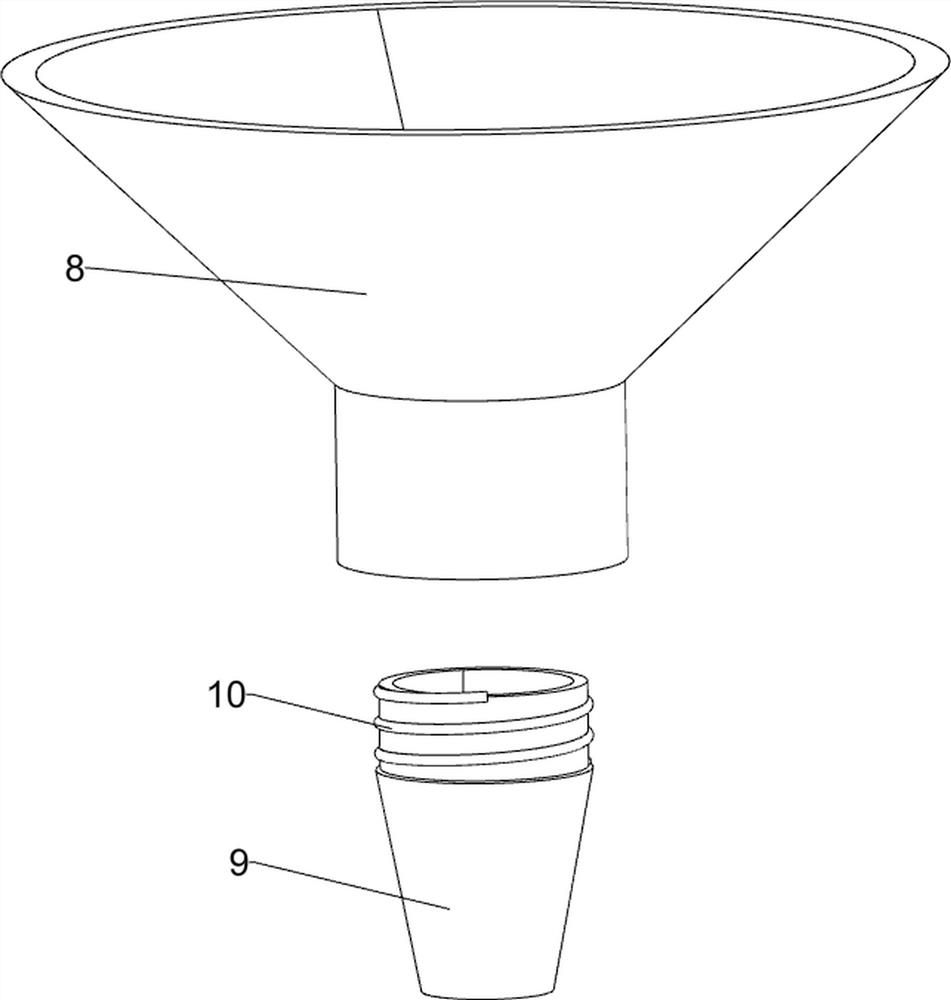

[0036] Such as Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, on the basis of Embodiment 2, a second support seat 7, a funnel 8 and a feed nozzle 9 are also included. A funnel 8, the bottom of the funnel 8 is provided with a feeding nozzle 9 through a screw thread 10.

[0037] On the other hand, the funnel 8 and the feeding nozzle 9 installed through the screw thread 10 can facilitate the injection of raw materials into the conical cylinder 44 , and the detachable feeding nozzle 9 avoids interference with the movement of the conical cylinder 44 .

[0038] It also includes a discharge valve 11, a connecting rod 12, a push rod 13, a C-shaped groove 14, a sliding pin 15 and a handle 16. There is a rectangular hole on the rear side of the lower part of the funnel 8, and a discharge valve 11 is slidingly arranged in the rectangular hole. , the rear side of the feeding valve 11 is provided with a through hole, the through hole of the feeding valve 11 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com