Husking roller combined structure suitable for corn seeds

A combined structure and seed corn technology, applied in the fields of application, agricultural machinery and implements, harvesters, etc., can solve the problems of low peeling rate of corn ears and difficult peeling, so as to meet the grain damage rate, reduce the damage rate and The effect of improving the shattering rate and improving the stripping rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The invention will be further described below with reference to the accompanying drawings and examples.

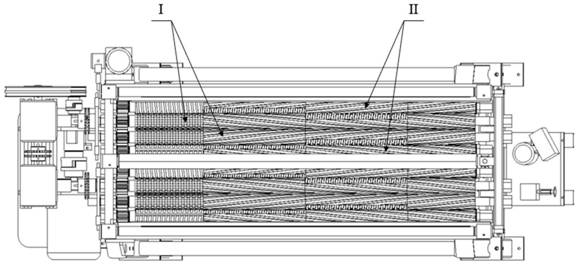

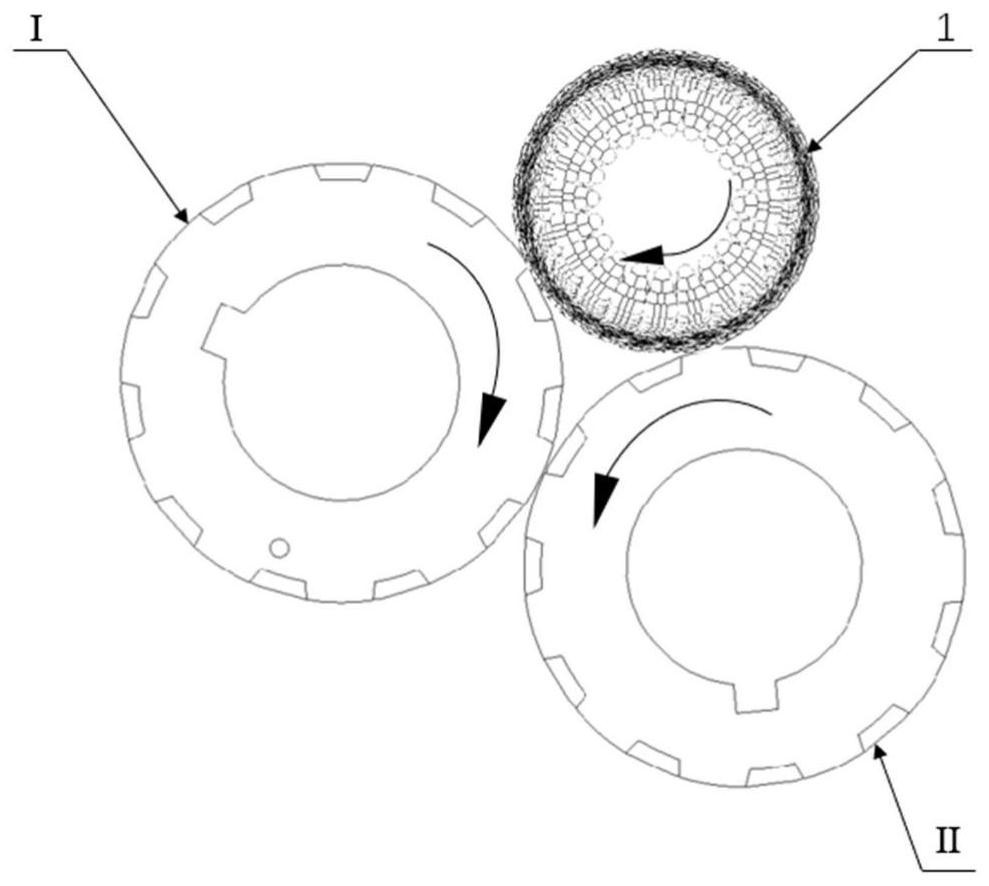

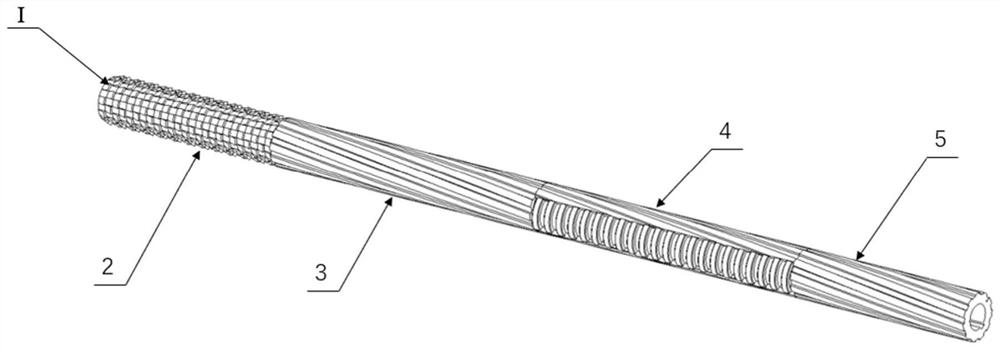

[0060] Such as Figures 1 to 7 As shown, a peeled roller combination structure suitable for seed corn includes a high-level peeled roller I and a low-peeled roller II having a high roller configuration.

[0061] The present invention employs a high and low roller configuration, two high peeled roller I and two low peeled roller II constitute a peeling monomer, wherein the horizontal height of two high peeled roller I is higher than the two low peeling rollers on both sides. The level of II is height; a low peeling roller II is configured with a high peeling roller 1 adjacent to its adjacent. One end of the roller shaft 12 of each peeling roller is secured to a drive gear 11, and adjacent transmission gear 11 mesh each other.

[0062] Such as figure 1 As shown, the high peeling roller I is rotated at the low peeling roller II. Preferably, if figure 1 As shown, the high pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com