Temperature influence testing device for computer mainboard

A technology for computer motherboards and testing devices, which is applied in measuring devices, electronic circuit testing, measuring electricity and other directions, can solve the problems of difficult motherboard temperature, maintenance, cumbersome and inconvenient installation process, etc., and achieves fast and simple installation process, improved accuracy, fast The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

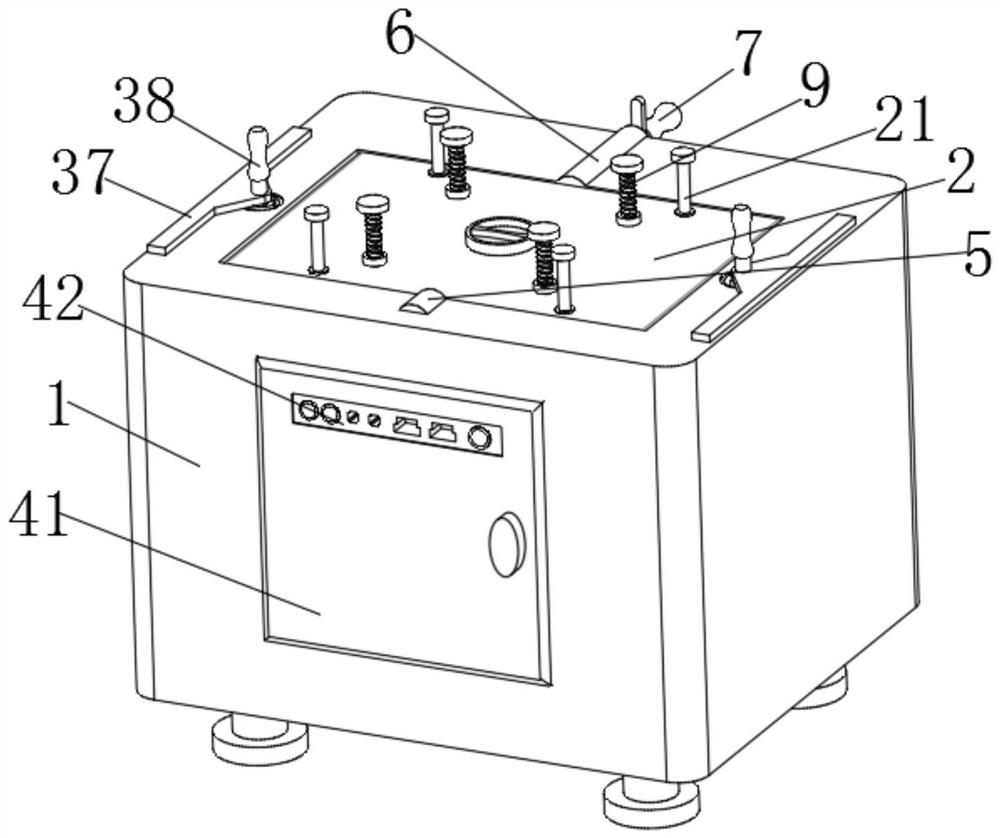

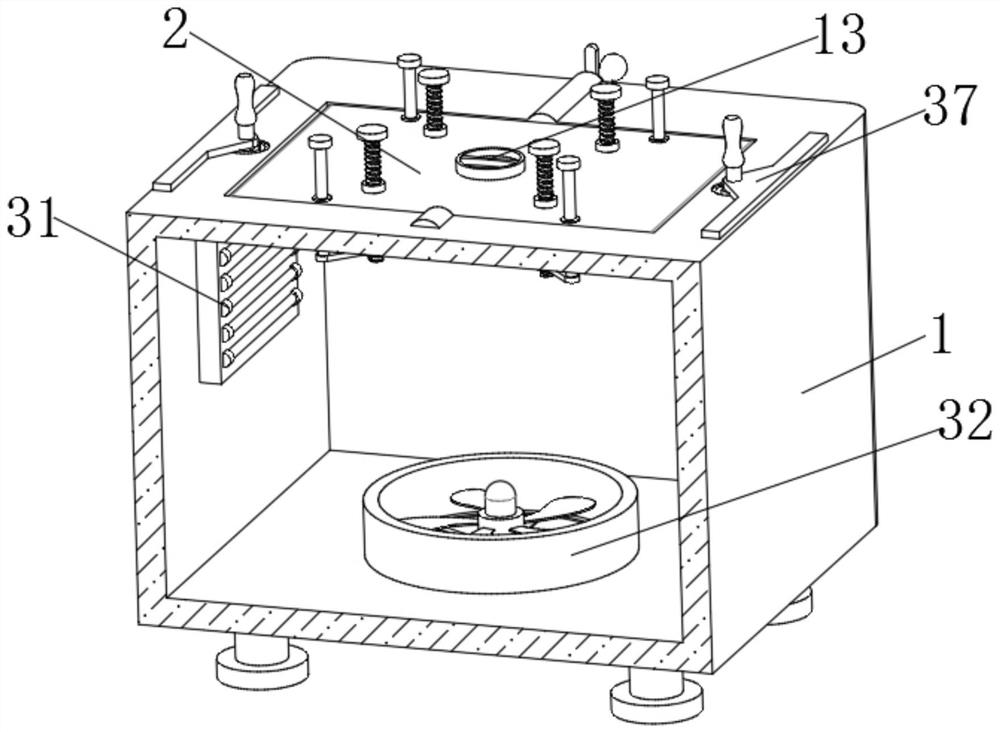

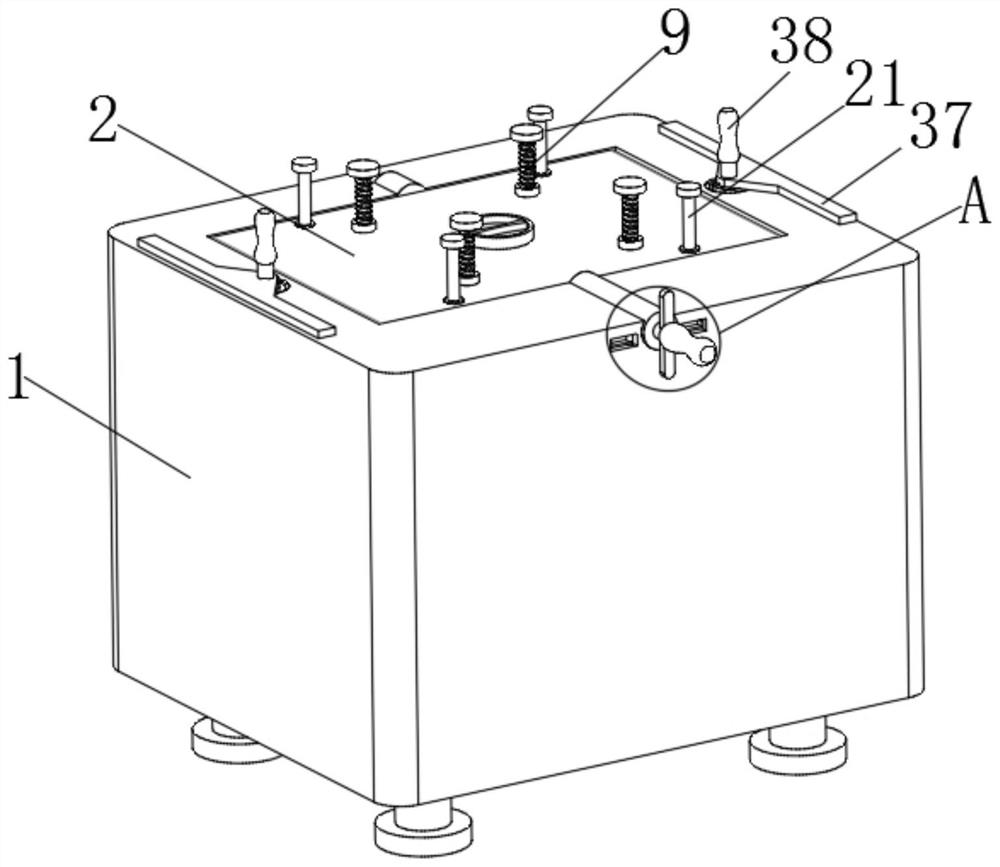

[0041] Example: Reference Figure 1-8 A temperature influence test device for a computer mainboard is shown, comprising an incubator 1, a turning hole is opened on the top of the keeping box 1, and a turning mounting plate 2 is arranged in the turning hole, and the two sides of the turning mounting plate 2 are respectively fixedly connected with short The rotating shaft 3 and the long rotating shaft 4, the overturning mounting plate 2 can make any flat plate in the prior art, such as a metal flat plate attached with an insulating layer, the short rotating shaft 3 and the long rotating shaft 4 can be any straight rod in the prior art, For example metal straight bar, short rotating shaft 3 and long rotating shaft 4 all can be fixedly connected with the both sides of overturning mounting plate 2 respectively by the mode of welding, and the top of incubator 1 is fixedly connected with short rotating drum 5 and long rotating drum 6, and short rotating shaft 3. One end of the long r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com