A method for predicting shale fracturing brittleness index during shale hydraulic fracturing

A technology of brittleness index and hydraulic fracturing, which is applied in the direction of applying stable tension/pressure to test material strength, measuring device, strength characteristics, etc., and can solve the problem that the accurate and effective brittleness index cannot be calculated in different regions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

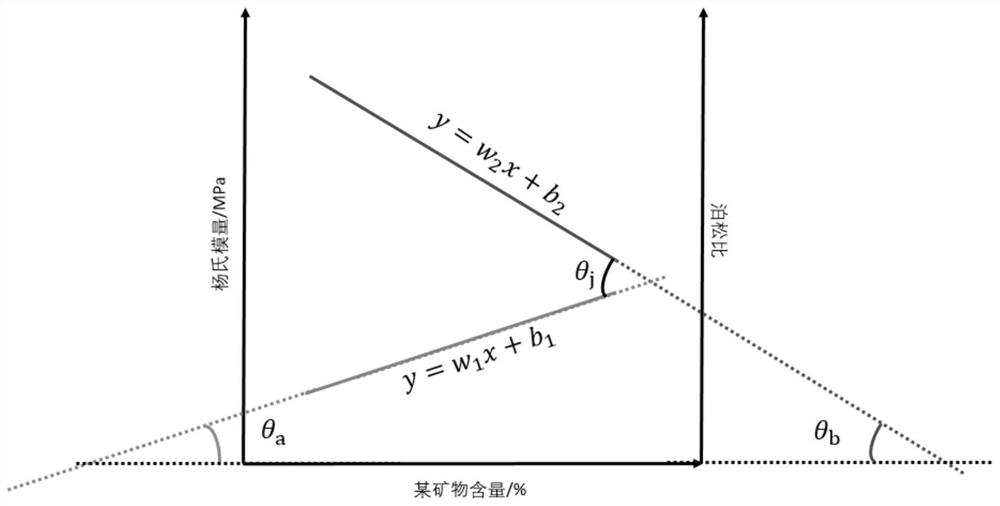

Method used

Image

Examples

Embodiment 1

[0086] The method for predicting the shale fracturing brittleness index of the present invention is applied to the test of specific shale samples, and the specific steps are as follows:

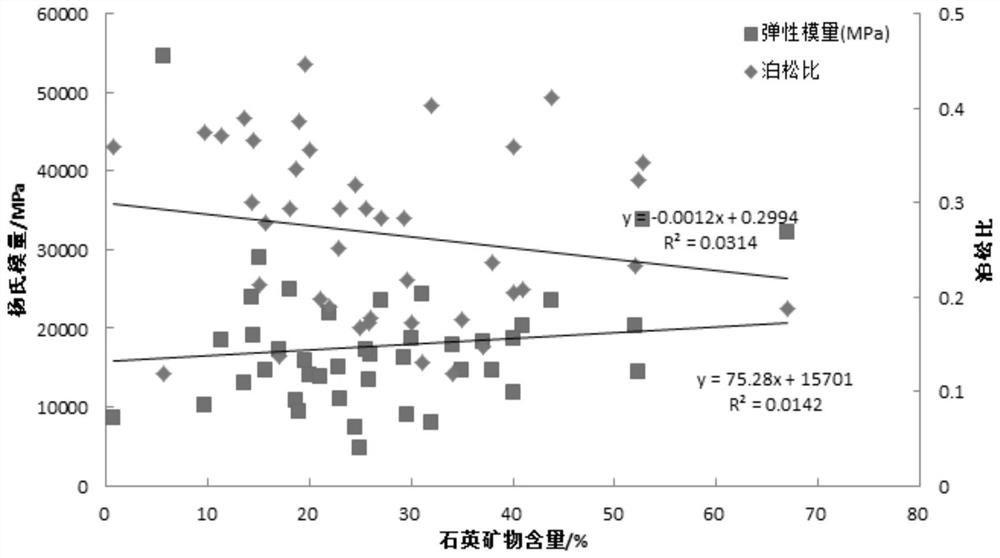

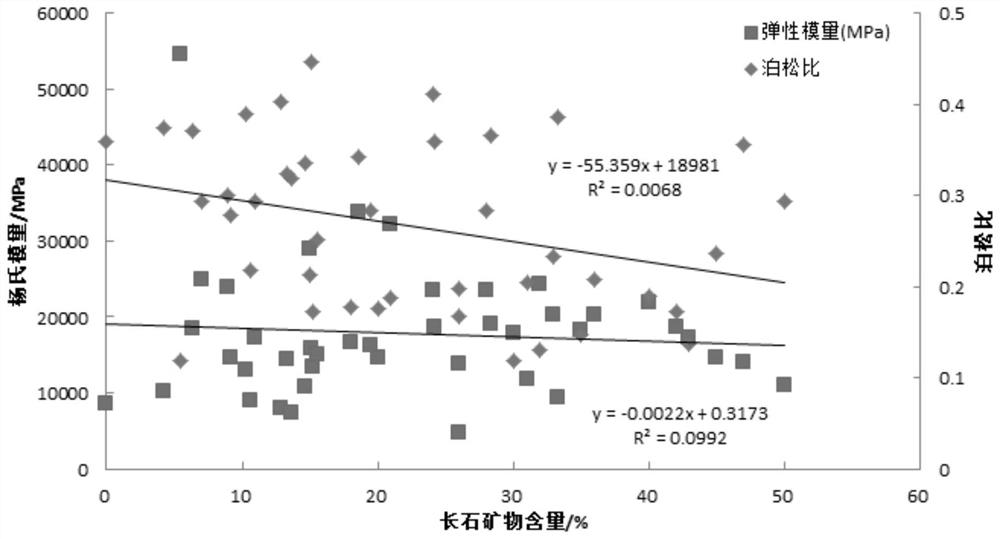

[0087] (1) Take 42 cores of Yongye 2 well for rock mineral analysis, numbered 1-42, and use X-ray diffractometer to measure the component content of various minerals. The specific data are shown in Table 1.

[0088] Table 1 The percentage of shale minerals

[0089]

[0090]

[0091]

[0092] (2) The corresponding Young's modulus and Poisson's ratio of the 42 cores were measured by the triaxial rock mechanics test system. The specific data are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com