Industrial product micro hole wall defect imaging device and identification algorithm

An industrial product and imaging device technology, which is applied in measuring devices, optical testing of defects/defects, material analysis through optical means, etc., can solve problems such as image distortion, inability to realize automation, and large volume of viewing inner wall lens, etc., to achieve simple use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

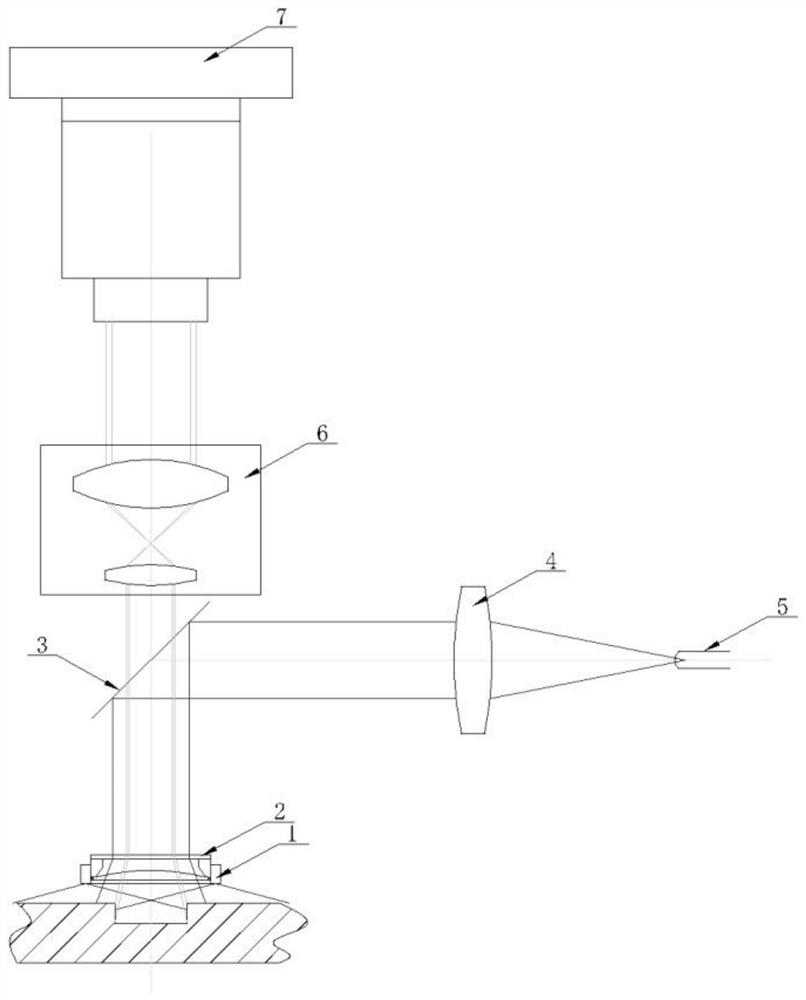

[0028] refer to figure 1 with figure 2 , an imaging device for micro-hole wall defects of industrial products, comprising an external high-power supplementary light 1, a semi-transparent and semi-reflective lens 3, an imaging zoom device 6, a photoelectric conversion sensor 7, and a parallel beam convex lens 4;

[0029] The external high-power supplementary light 1 is provided with a liquid lens 2 to detect suspicious holes;

[0030] The parallel beam convex lens 4 is used in conjunction with the point light source 5;

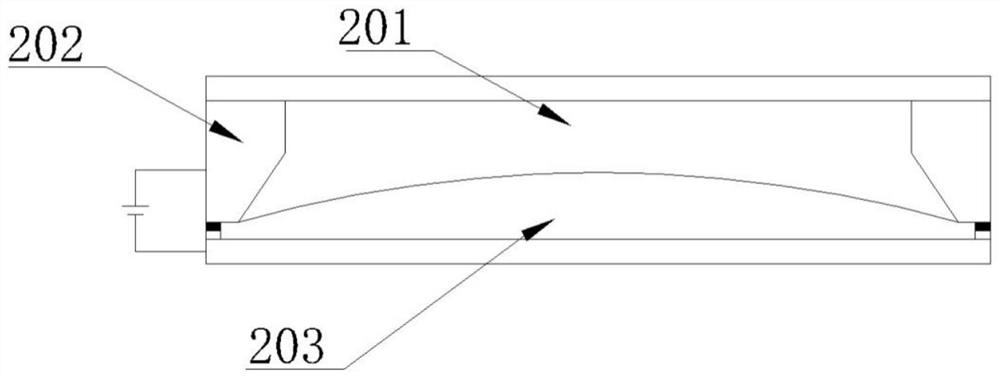

[0031] The liquid lens 2 includes a liquid lens oil cavity 201, a piezoelectric ceramic 202 and a liquid lens water cavity 203;

[0032] An algor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com