Air filtering structure for negative pressure isolation tent

An air filtration and negative pressure isolation technology, applied in tents/canopies, applications, household heating, etc., can solve problems such as cross-infection, poor reliability, and inability to target treatment, and achieve the effect of reducing consumables and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

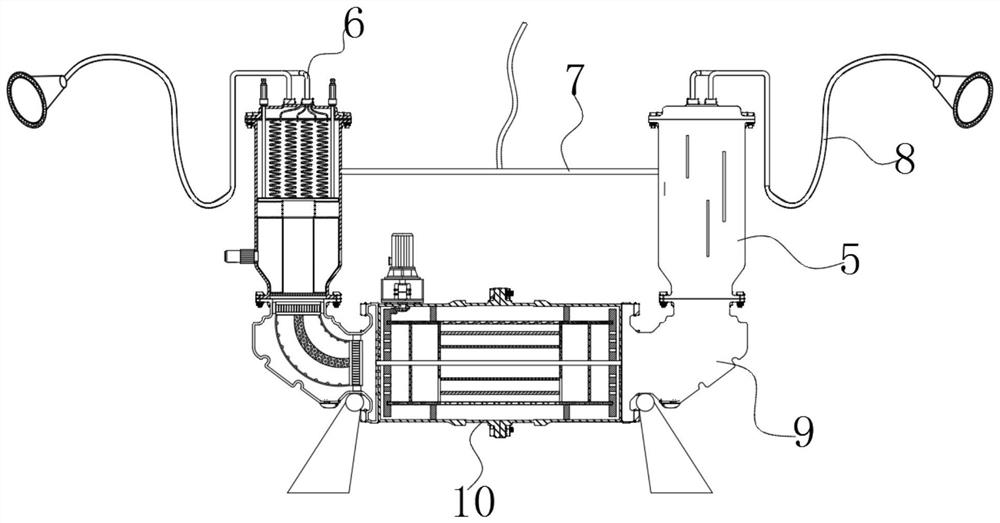

[0042] see Figure 1~4 , in an embodiment of the present invention, an air filter structure for a negative pressure isolation tent, including a suction pan 2, an air filter assembly 3 and a discharge pipe 4, wherein the suction end of the suction pan 2 is connected to the tent 1 are connected so as to reduce the air pressure in the tent 1 to form a negative pressure inside;

[0043] The suction disc 2 can suck the air in the tent 1 into the air filter assembly 3, and discharge it through the discharge pipe 4;

[0044] Two suction discs 2 are symmetrically connected to the air filter assembly 3;

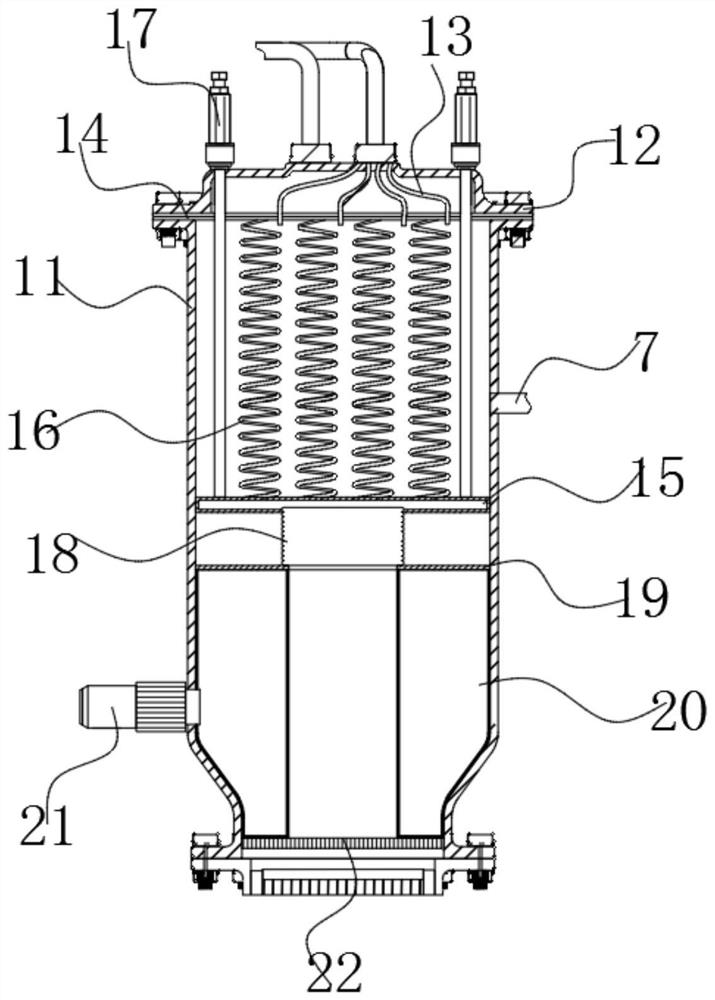

[0045]The air filter assembly 3 includes a high-temperature sterilization assembly 5, a middle section sterilization assembly 9, and a germ adsorption assembly 10, wherein the two suction pans 2 respectively suck the air in the corresponding tent 1 and transfer it to the corresponding tent 1 in sequence. In the high-temperature sterilization assembly 5 and the middle section of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com