Electromagnetic suspension type air spring and railway vehicle

An air spring and electromagnetic levitation technology, applied in the direction of magnetic springs, springs, springs/shock absorbers, etc., can solve problems that affect the reliability of vehicle operation, cannot achieve active vibration reduction, and poor vibration reduction performance, and achieve vibration reduction Good effect, small rigidity and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

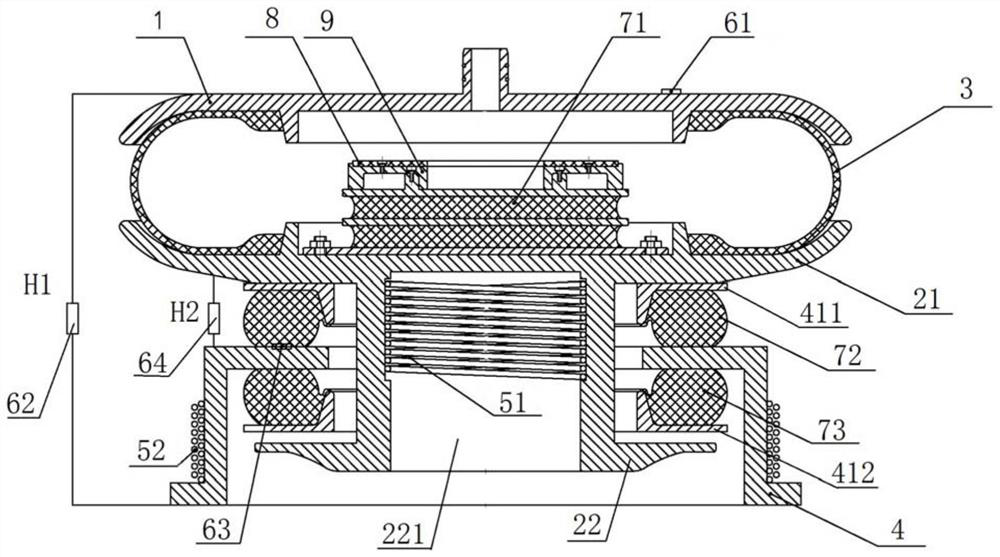

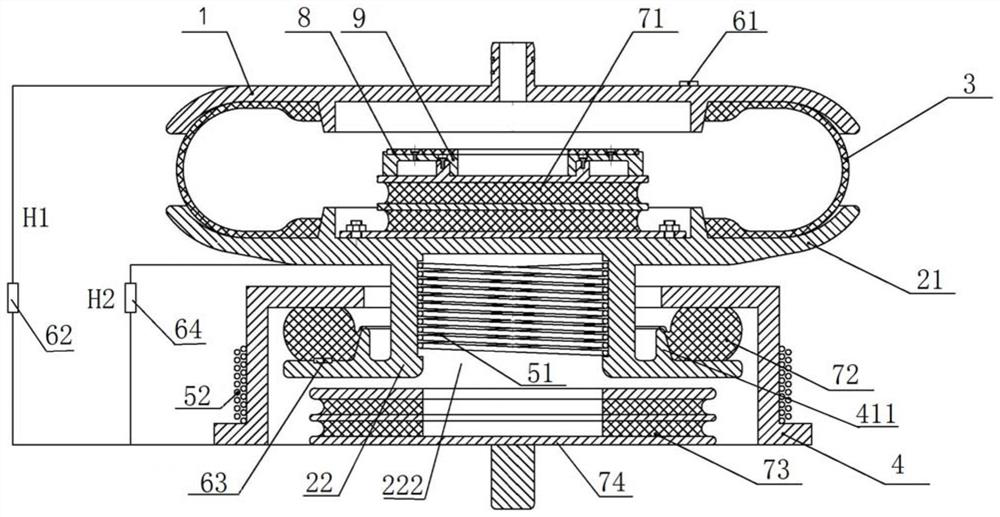

[0041] figure 1 As shown, in a schematic embodiment 1 of an electromagnetic levitation air spring provided by the present invention, the air spring includes:

[0042] upper cover 1;

[0043] Lower cover, lower cover includes:

[0044] A cover plate 21, the cover plate 21 is arranged opposite to the upper cover 1 at intervals;

[0045] The support 22, the support 22 is connected under the cover 21, and the support 22 is hollow inside and the cover 21 forms a first accommodating cavity 221;

[0046] The air bag 3 is arranged between the cover plate 21 and the upper cover 1, and the air bag 3 forms an air cavity with the cover plate 21 and the upper cover 1;

[0047]A base 4, the base 4 is sleeved on the outside of the support 22, and the base 4 is connected to the car body bogie;

[0048] The electromagnetic levitation module includes a first coil 51 and a second coil 52 powered on, the first coil 51 is set in the first accommodation chamber 221; the second coil 52 is sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com