Assembly type special rail connecting structure and using method thereof

A rail connection and assembly technology, applied in the direction of rails, rail joints, roads, etc., to achieve the effect of increasing compressive resistance and structural strength, increasing functionality, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

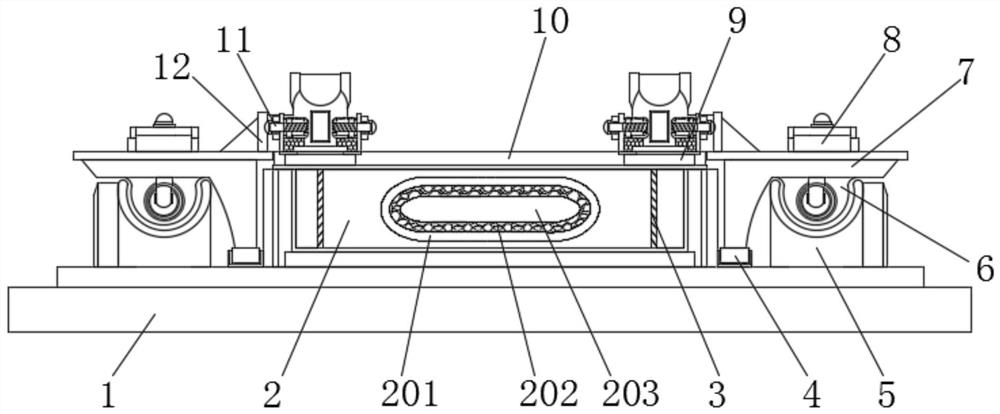

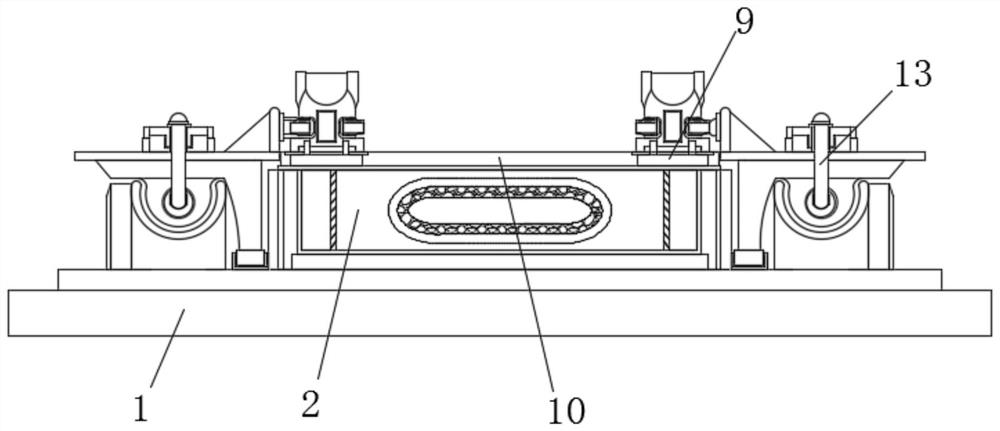

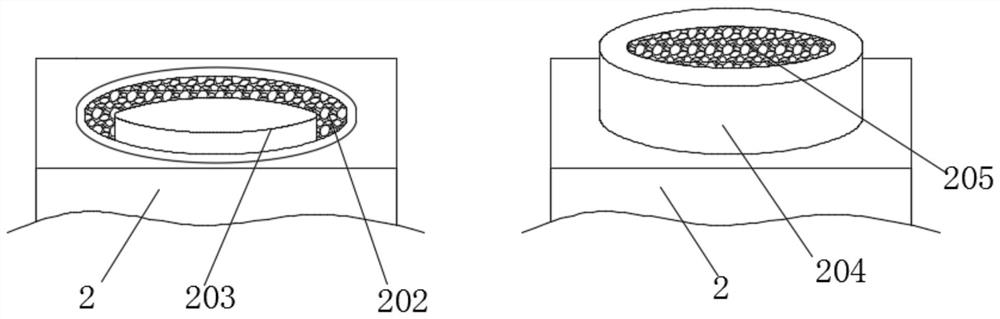

[0035] see Figure 1-7 , the present invention provides a technical solution: an assembled special track connection structure, including a prefabricated base 1, a pressure-bearing groove 2 is provided at the middle position of the top of the prefabricated base 1, and a pressure-bearing groove 2 is provided inside the pressure-bearing groove 2. Buffer assembly, the two sides of the top of the prefabricated base 1 are provided with semi-arc-shaped slide grooves 5, the bottom of both sides of the pressure-bearing groove 2 is provided with guide grooves 4, and the inner sides of the two sets of guide grooves 4 are provided with mutually matching mounting brackets 7, The sides of the bottoms of the two groups of mounting frames 7 that are far away from each other are provided with arc-shaped sliding sleeves 6 that are compatible with the semi-arc-shaped chute 5, and the tops of the two groups of mounting frames 7 are provided with engaging blocks 8, and the two groups of arc-shaped ...

Embodiment 2

[0042] see Figure 1-7 , the present invention provides a technical solution: an assembled special track connection structure, including a prefabricated base 1, a pressure-bearing groove 2 is provided at the middle position of the top of the prefabricated base 1, and a pressure-bearing groove 2 is provided inside the pressure-bearing groove 2. Buffer assembly, the two sides of the top of the prefabricated base 1 are provided with semi-arc-shaped slide grooves 5, the bottom of both sides of the pressure-bearing groove 2 is provided with guide grooves 4, and the inner sides of the two sets of guide grooves 4 are provided with mutually matching mounting brackets 7, The sides of the bottoms of the two groups of mounting frames 7 that are far away from each other are provided with arc-shaped sliding sleeves 6 that are compatible with the semi-arc-shaped chute 5, and the tops of the two groups of mounting frames 7 are provided with engaging blocks 8, and the two groups of arc-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com