Protective device for hot galvanizing process

A protective device, hot-dip galvanizing technology, applied in the direction of hot-dip galvanizing process, metal material coating process, coating, etc., can solve the problems of reducing work efficiency, slow moving speed, and need to increase the protective effect and increase mobility Sexuality, novel design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

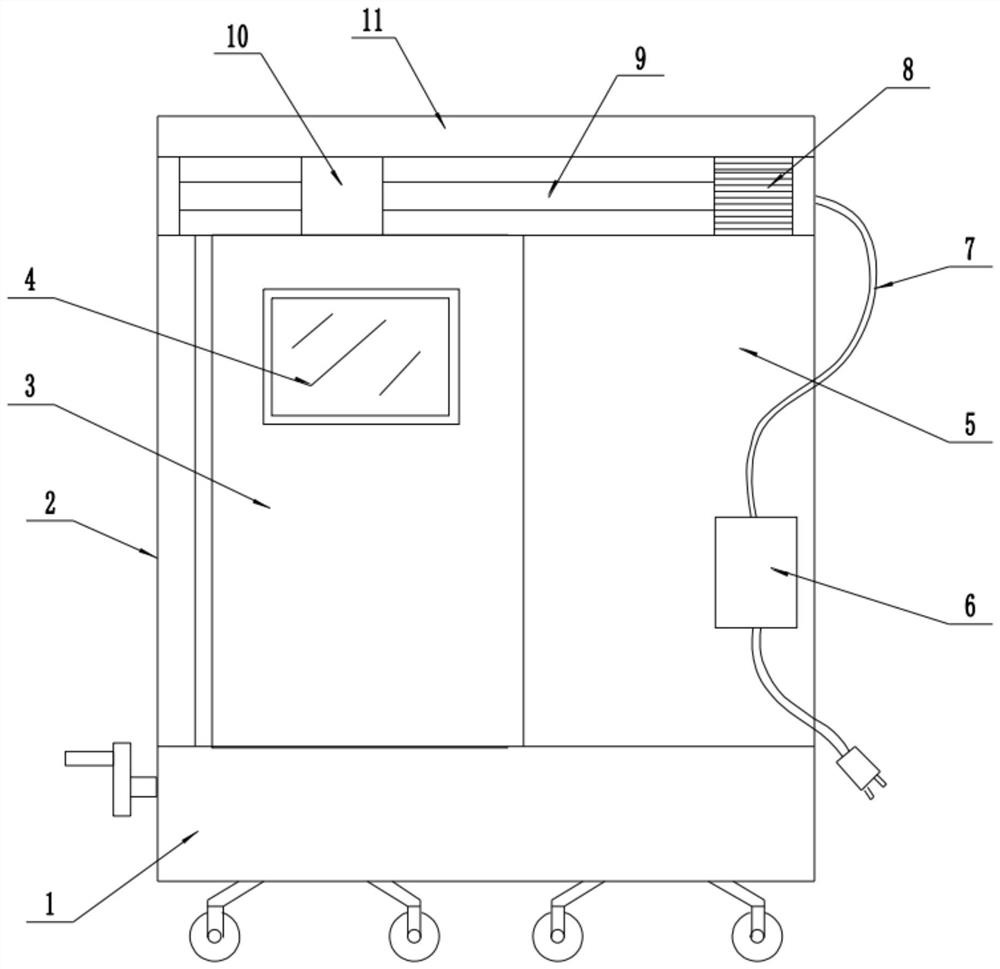

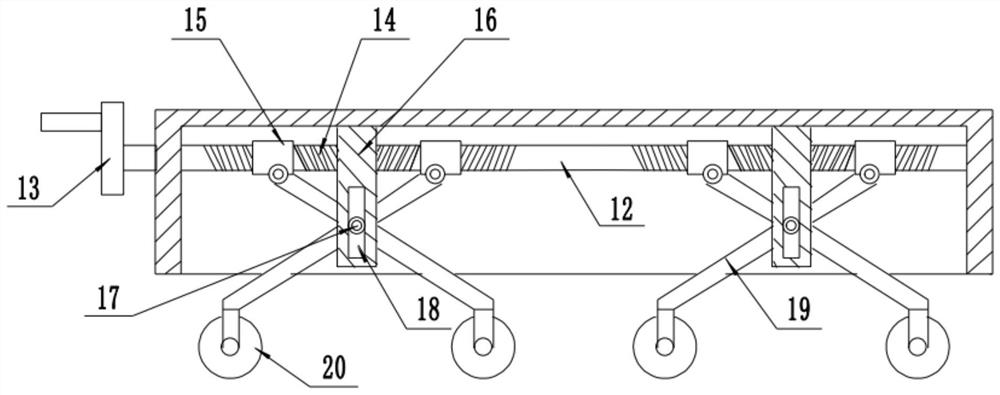

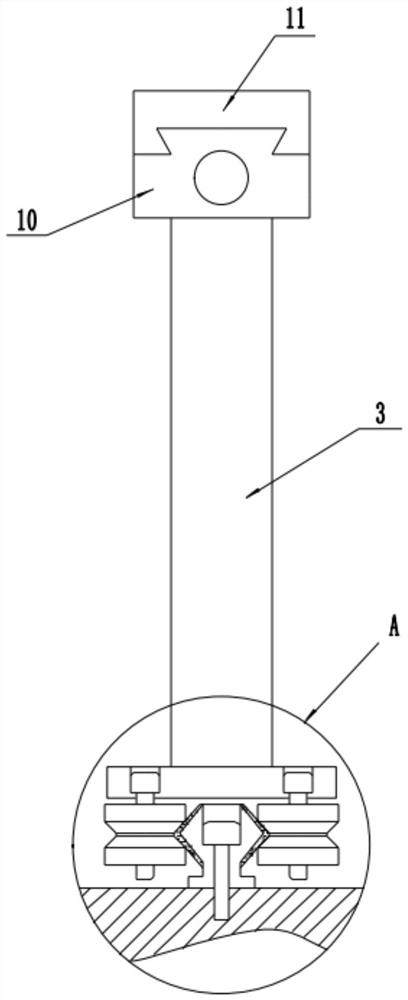

[0032] refer to Figure 1~6 , in an embodiment of the present invention, a protective device for hot-dip galvanizing process includes two moving frames 1 at the front and rear, and a protective shell 2 is installed between the two sides of the moving frame 1 to form a sealed space, ensuring the safety of the staff. Protective effect, the fixed door 5 is installed on the right side of the upper end of the front mobile frame 1, the left side of the fixed door 5 is provided with a movable door 3, the upper end of the movable door 3 is equipped with a sliding block 10, and the top of the sliding block 10 is provided with a trapezoidal block 27, and the trapezoidal block 27 The upper end slides inside the sliding guide rail 11, and the middle part of the lower end of the sliding guide rail 11 is provided with a dovetail groove that cooperates with the trapezoidal block 27. The dovetail groove and the trapezoidal block 27 are provided to ensure the stability of the sliding block 10 d...

Embodiment 2

[0034]In another embodiment of the present invention, a protective device for hot-dip galvanizing process includes two moving frames 1 at the front and rear, a protective shell 2 is installed between the two sides of the moving frame 1, and a fixed door is installed on the right side of the upper end of the front moving frame 1 5. A movable door 3 is provided on the left side of the fixed door 5, and a sliding block 10 is installed on the upper end of the movable door 3. The top of the sliding block 10 is provided with a trapezoidal block 27, and the upper end of the trapezoidal block 27 is slid inside the sliding guide rail 11. The middle part of the lower end of the 11 is provided with a dovetail groove that cooperates with the trapezoidal block 27, and the middle part of the sliding block 10 is also provided with an internally threaded hole 28 that cooperates with the screw 9. The middle part of the sliding block 10 is installed with the screw 9 through a thread structure. R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com