Automatic conveying and winding device for plastic film production

A plastic film and winding device technology, applied in the field of plastic manufacturing, can solve the problems of low winding efficiency, cooling operation, plastic film wrinkles, etc., and achieve the effect of improving winding quality, improving winding efficiency, and improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be embodied in various ways of claims defined and covered.

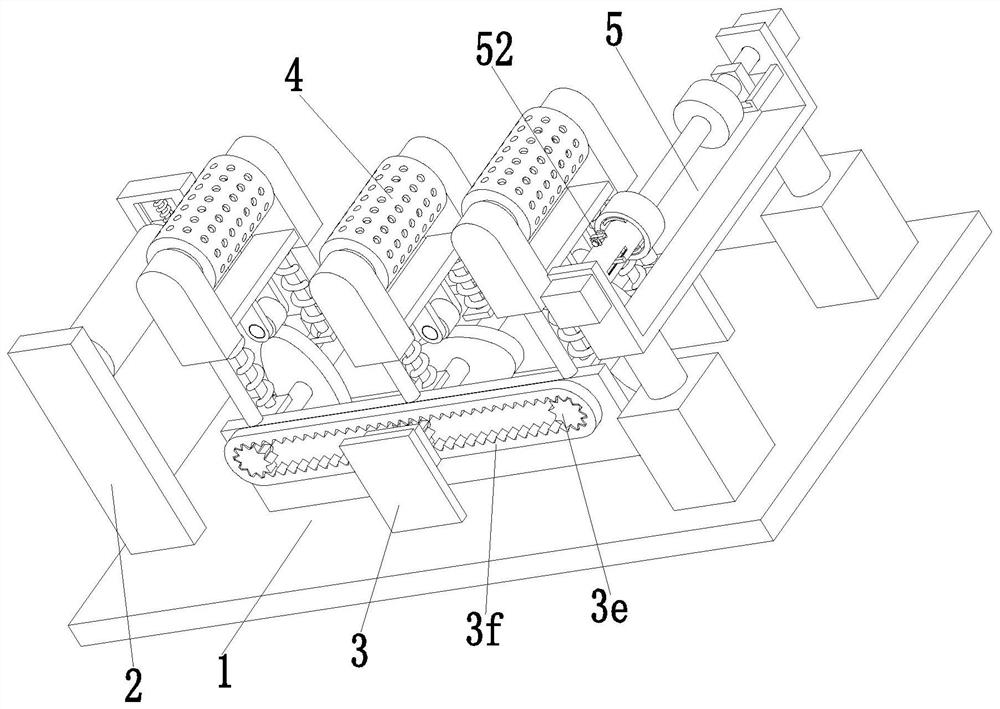

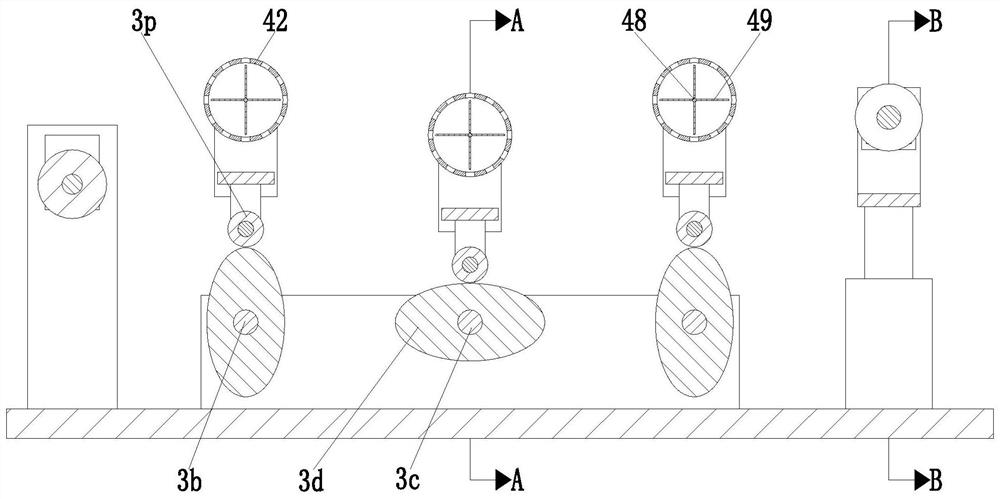

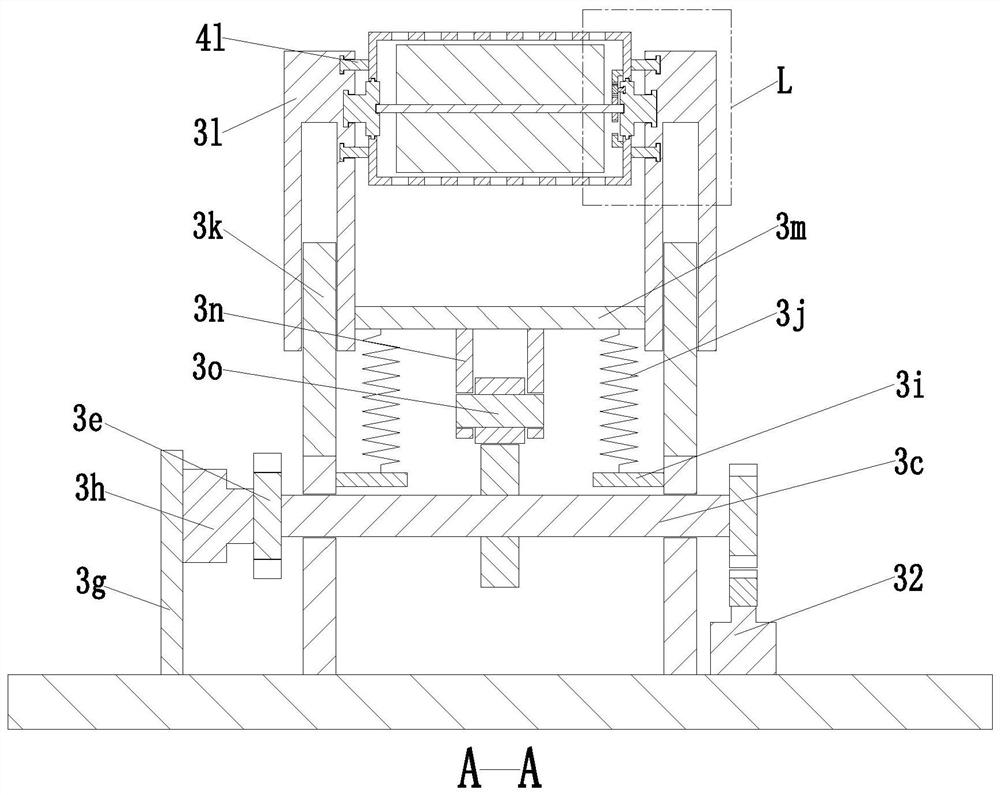

[0033] Such as Figures 1 to 10 As shown, a plastic film produces an automated conveying device, including a bottom plate 1, a feed mechanism 2, a top rising mechanism 3, a heat sink 1, and a winding mechanism 5, and the upper left end is fitted with a feed mechanism 2, The bottom plate 1 is mounted with a winding mechanism 5, and the bottom plate 1 is mounted having a rising mechanism 3, and a heat dissipation mechanism 4 is mounted on the top rising mechanism 3.

[0034] The winding mechanism 5 includes a lifting cylinder 5a, a U-plate 5b, a one motor 5c, a positioning a rod 5D, a positioning plate 5e, a cardboard 5F, a straight rod 5g, and a push plate 5i, slide The rod 5j, the arc panel 5K, the return spring rod 5L, the rubber plate 5m, the winding round roller 5N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com