Quantitative pouring and taking container

A container and quantitative cavity technology, which is applied to the field of quantitatively pourable containers, can solve the problems of large space occupation, large placement space and high manufacturing cost, and achieve the effects of small space occupation, reasonable design and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Attached below Figure 1-23 Embodiments of the invention will be described in detail.

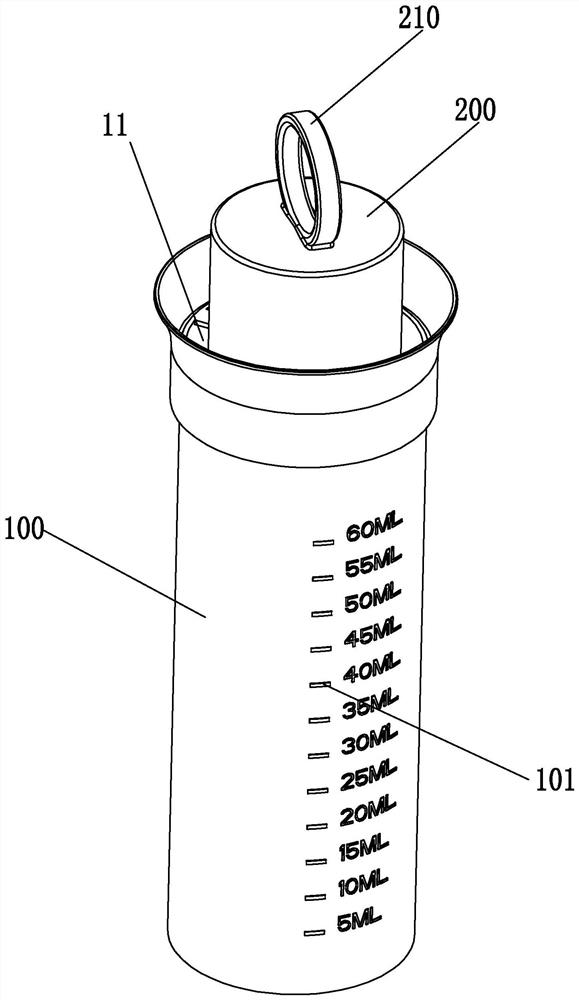

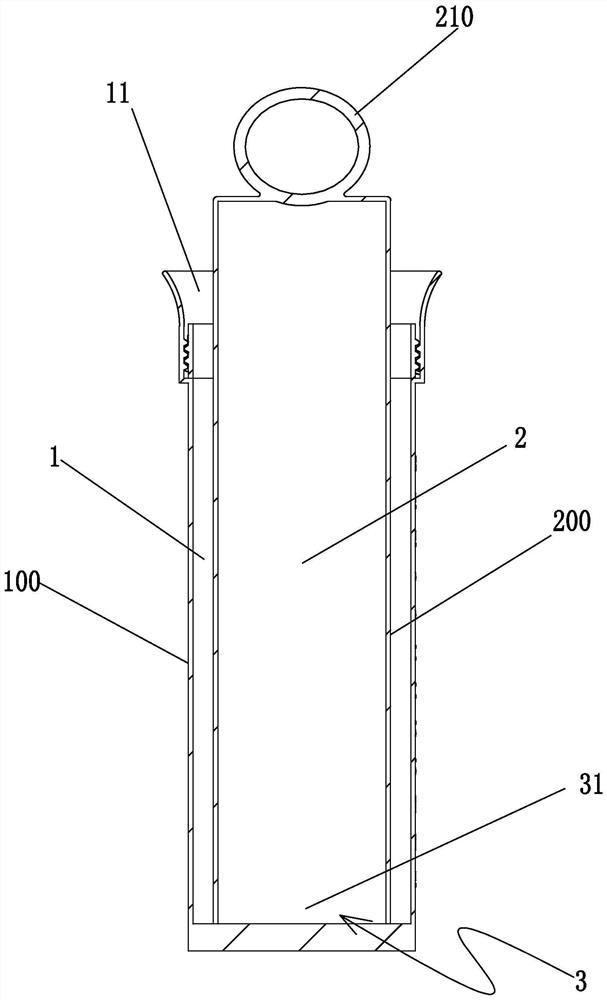

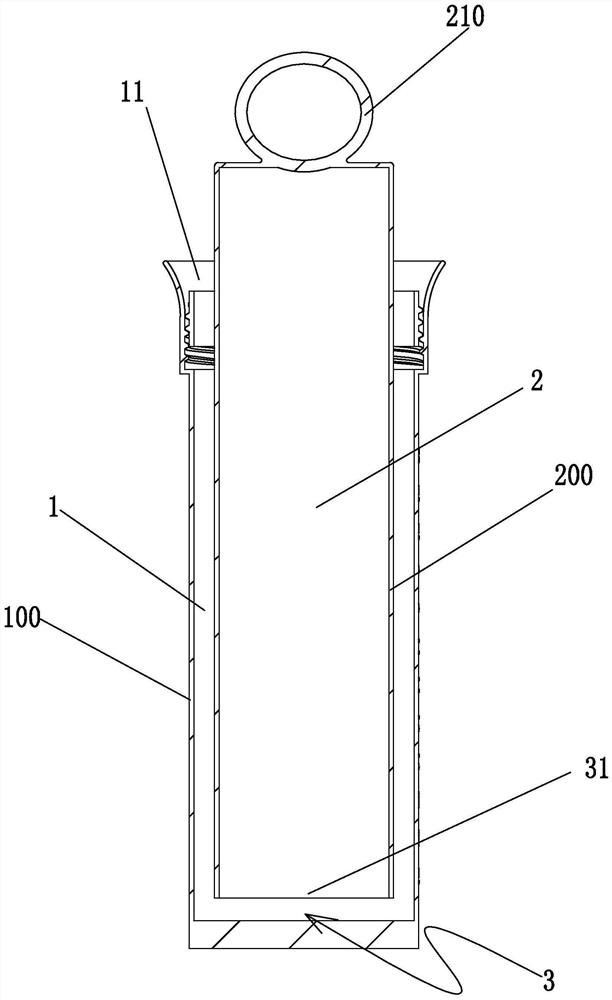

[0050] like Figure 1-9 As shown, a quantitative pouring container of the present invention includes an open container body 100, the inner cavity of the container body 100 is formed with a quantitative cavity 1, and the quantitative cavity 1 of the container body 100 is provided with a liquid pouring port 11, The container body 100 is movably connected with a valve sleeve 200, and the inner cavity of the valve sleeve 200 is formed with a liquid storage chamber 2, and a valve sleeve 200 is provided between the liquid storage chamber 2 and the quantitative chamber 1. The liquid inlet control structure 3 that can make the liquid storage chamber 2 communicate with the quantitative chamber 1 or isolate it. When in use, the user acts on the valve sleeve to move relative to the quantitative chamber, which can open the liquid inlet control structure, so that the liquid in the liquid storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com