Auxiliary unloading equipment for express transport vehicle

A technology for transport vehicles and equipment, which is applied to vehicles with screw conveyors, etc., which can solve the problems of heavy physical exertion and heavy workload for staff, and achieve the effects of reducing workload, improving loading efficiency, and preventing goods from falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples or drawings are used to illustrate the present invention, but not to limit the scope of the present invention.

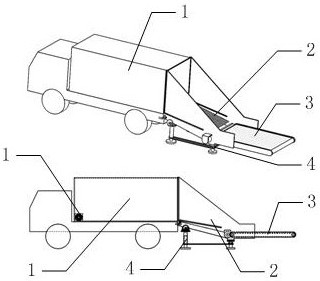

[0048] like figure 1 , 2As shown, it includes an unloading module 2, a conveyor belt 5, and a winding mechanism 6, wherein the winding mechanism 6 is installed on the bottom surface of the compartment 1 and is close to the front of the vehicle.

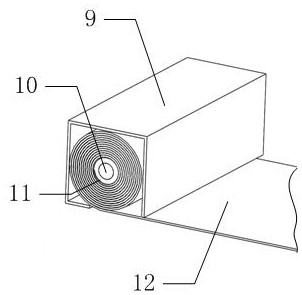

[0049] like image 3 , 4 As shown, the above-mentioned winding mechanism 6 includes an installation shell 9, an installation shaft 10, a winding roller 11, and a scroll spring 13, wherein the installation shaft 10 is rotatably installed in the installation shell 9, and the winding roller 11 is fixedly installed on the installation shaft 10; two The scroll spring 13 is installed symmetrically at both ends of the installation sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com