Multilayer digital ink-jet printing machine

A digital inkjet and printing machine technology, applied in typewriters, printing, printing devices, etc., can solve the problems of printing and dyeing heads that are easy to disperse ink, and achieve the effects of improving printing and dyeing effects, preventing mutual erosion, and improving coagulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

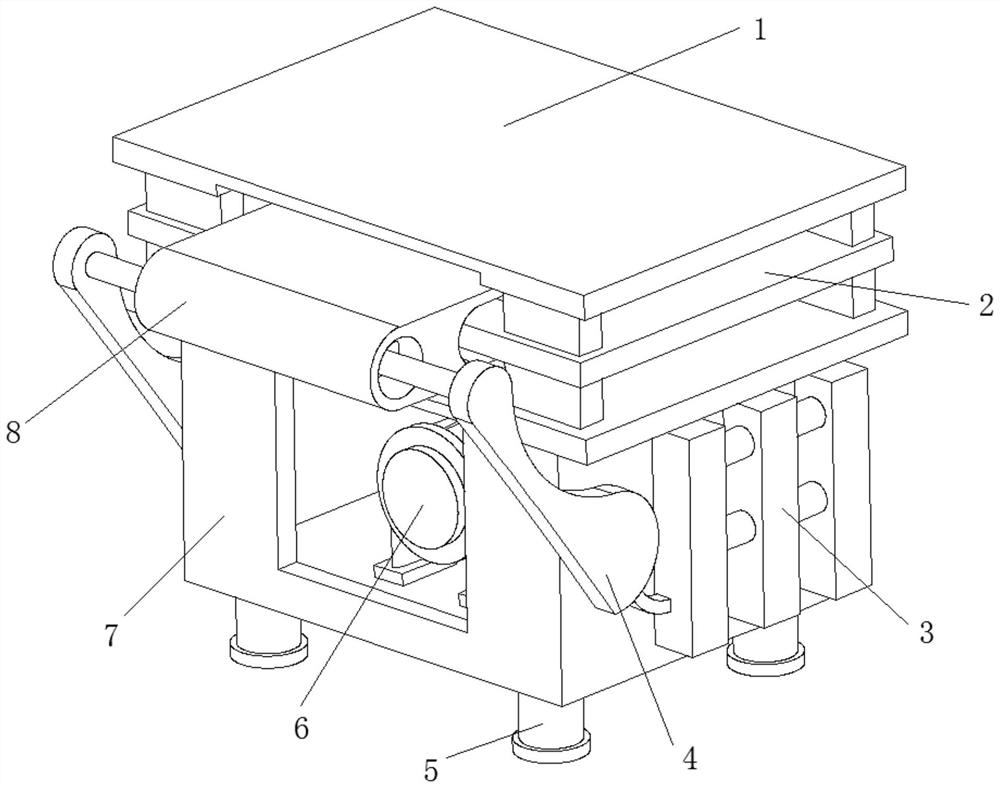

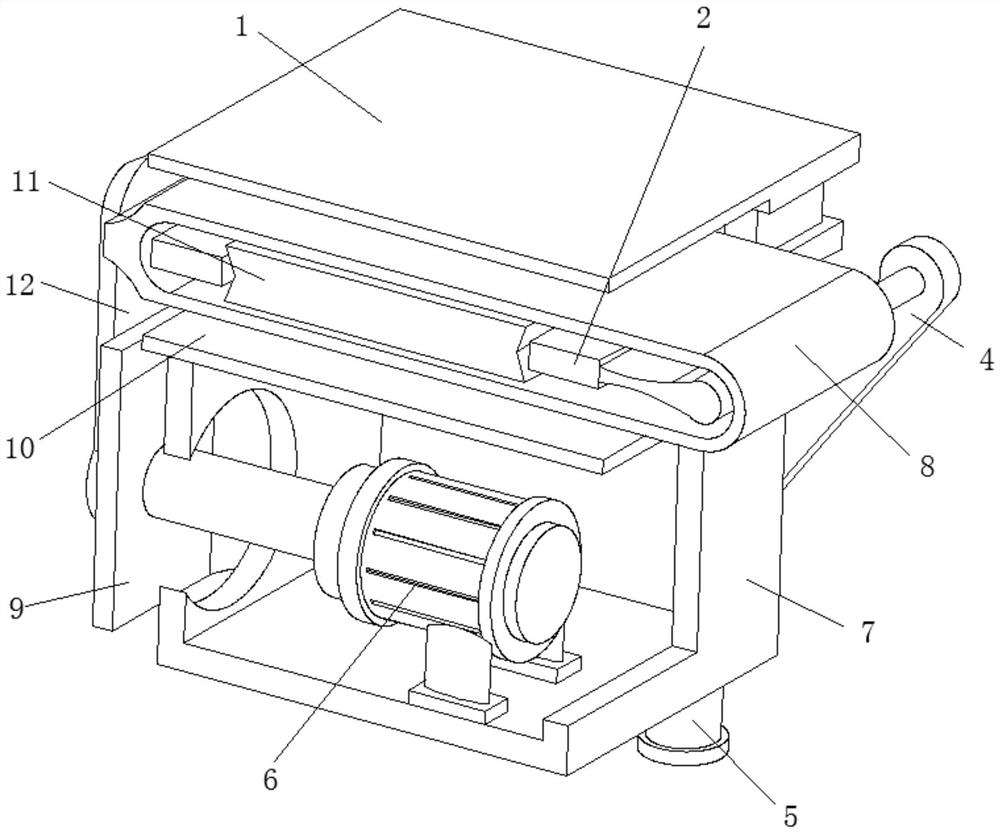

[0037] Such as Figure 1-3 As shown, the present invention provides a technical solution: a multi-layer digital inkjet printing machine, including a printing shell 7, the bottom of the printing shell 7 is fixedly connected with a support foot 5, and the front of the printing shell 7 is fixedly connected with a An ink bag 3, the left side of the ink bag 3 is fixedly connected with a support transmission rod 4, the bottom of the inner cavity of the printed casing 7 is fixedly connected with a servo motor 6, and the back of the printed casing 7 is fixedly connected with a transmission backplane 9 , the output end of the servo motor 6 is drive-connected to the surface of the transmission backplane 9, and the top of the printing shell 7 is respectively fixedly connected with the third printing plate 10, the second printing plate 2 and the first printing plate 1 through a support block. , and the third printing plate 10, the second printing plate 2 and the first printing plate 1 are...

Embodiment 2

[0047] Such as Figure 4-5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the two sides of the permeation box 111 are provided with inlet and outlet air holes 112, and the outer surface of the permeation box 111 is sleeved on the second printing plate. On the surface of the board 2 , the inside of the permeation box 111 is provided with a built-in plastic case 115 , and the inside of the built-in plastic case 115 is provided with an air bag 116 . Through the setting of the airbag 116, when the printing and dyeing target is the cloth, the cloth under the high stretching effect can prevent the surface of the blocking device 113 from being hard damaged on the cloth under the high stretching effect, and the air inlet and outlet holes 112 can be connected to the exhaust fan at the same time. When the blocking device 113 moves down, the through hole 118 produces convective air, so that the printing and dyeing ink on the printing object s...

Embodiment 3

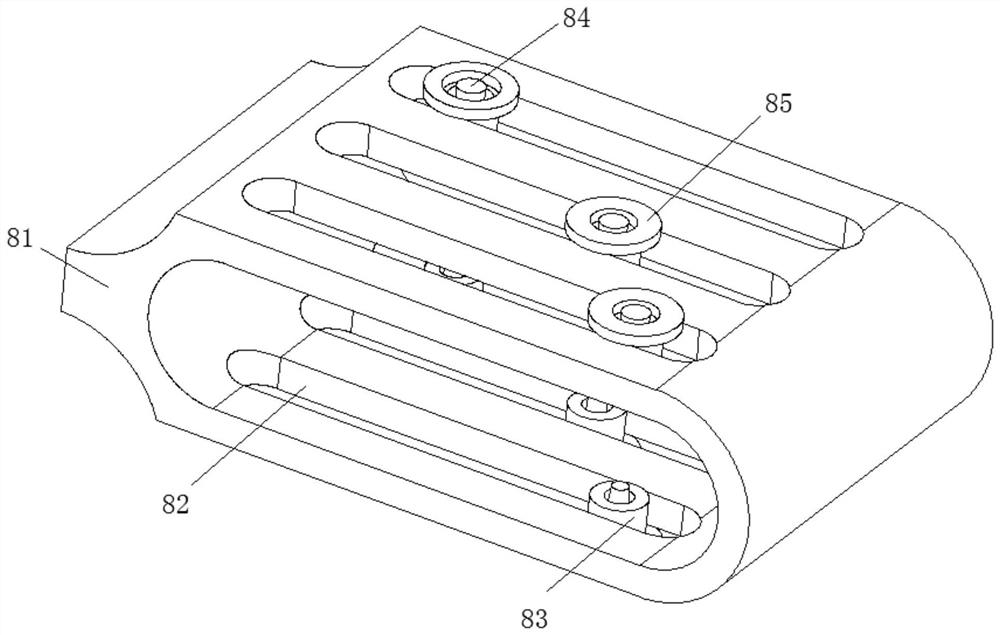

[0053] Such as Figure 6-8 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the blocking device 113 includes a baffle 1131, and the bottom of the baffle 1131 is fixedly connected to the end of the spring 114, so A fixing block 1132 is fixedly connected to the top of the baffle 1131 , the outer surface of the fixing block 1132 is sleeved inside the through hole 118 , and the top of the fixing block 1132 is provided with a slot 1136 .

[0054] The inside of the slot 1136 is fixedly connected with a rotating shaft 1134, and the outer surface of the rotating shaft 1134 is rotatably connected with a rotating block 1133. The bottom of the rotating block 1133 is fixedly connected to the bottom of the slot 1136 through an elastic rod 1135. The outer surface of the block 1133 is fixedly connected with a scraper device a. Through the setting of the elastic rod 1135, it can prevent the hard damage to the rotating block 1133 wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com