A mine-used built-in piston mechanical claw

A technology of piston type and mechanical claws, which is applied in the field of built-in piston type mechanical claws for mining, can solve the problems of large pick-up space for drill pipes, and achieve the effects of compact pick-up structure design, saving transposition space, and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

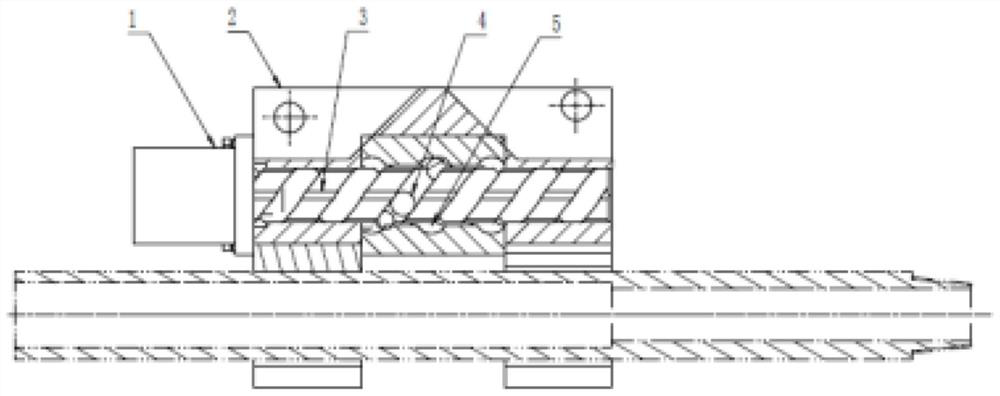

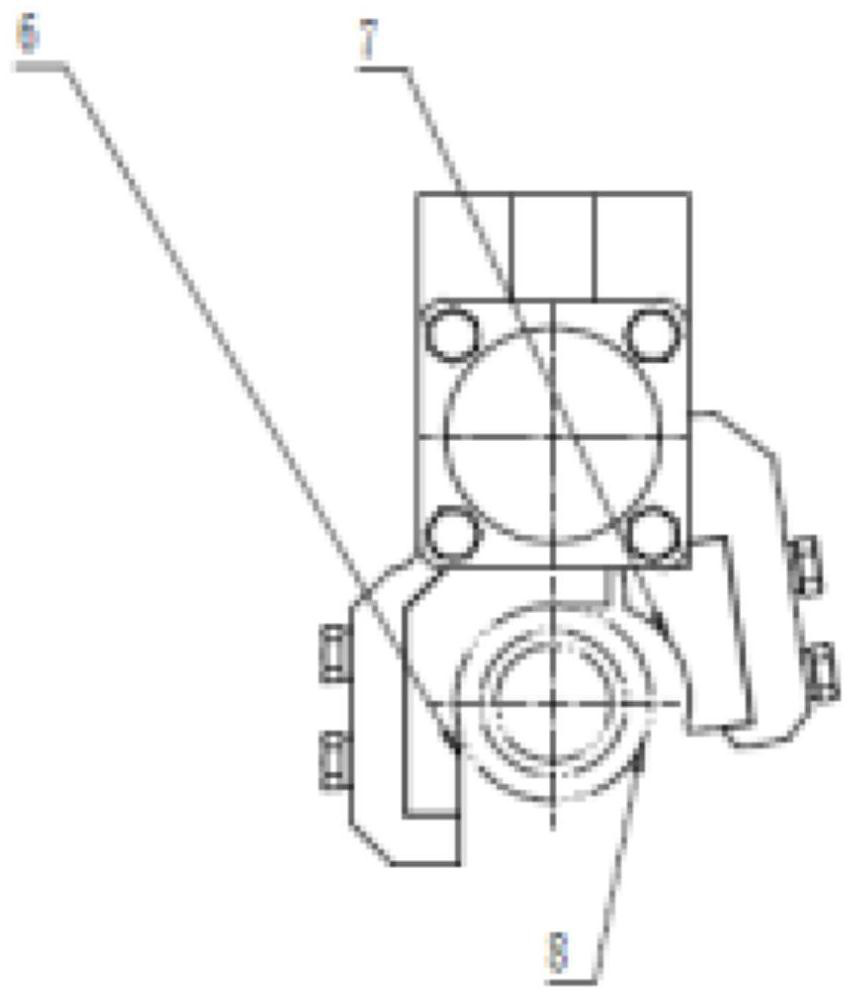

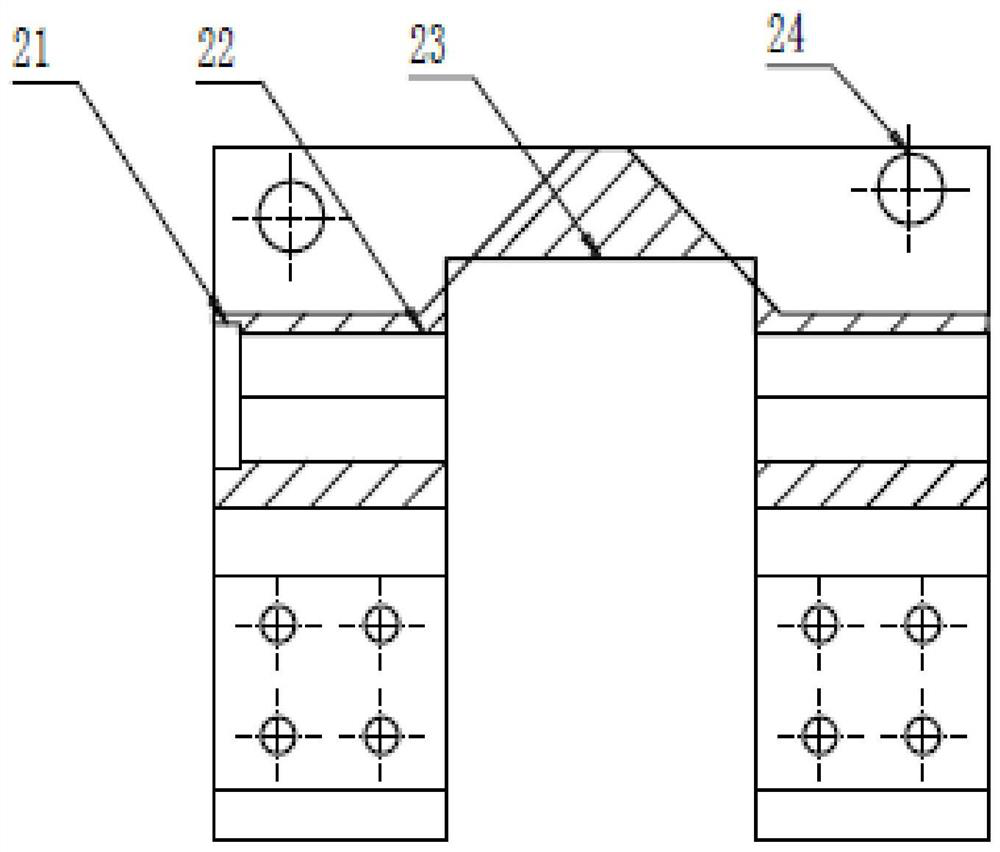

[0038] A mine piston type mechanical claw, such as Figure 1 to Figure 7 As shown, it includes a fixed claw 2, a movable claw 5, a telescopic shaft 3, a ball, a ball fixing frame and a driving device 1, and the driving device 1 drives the telescopic shaft 3 to move along the guide hole 22 provided on the fixed claw 2, and passes through the ball. The movement converts the thrust of the driving device into the clamping force of the movable jaw. The relative installation position and specific structure and function of each component are as follows:

[0039] Driving device 1: a hydraulic cylinder, parallel to the axis of the drill pipe 8, providing clamping power, installed at one end of the fixed claw 2, the piston of the hydraulic cylinder is connected with the telescopic shaft 3, and drives the telescopic shaft 3 to guide the hexagonal direction of the fixed claw 2 Axial movement in the hole.

[0040]Fixed claw 2: One end of the fixed claw 2 is connected with the hydraulic cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com