Automatic vending machine for light and thin commodities

A technology for automatic vending machines and commodities, which is applied to coin-free or similar appliances, coin-operated equipment for distributing discrete items, and coin-operated equipment for distributing discrete items, etc. Problems such as troublesome maintenance and large equipment volume, to achieve the effect of convenient product placement, high reliability and small equipment volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

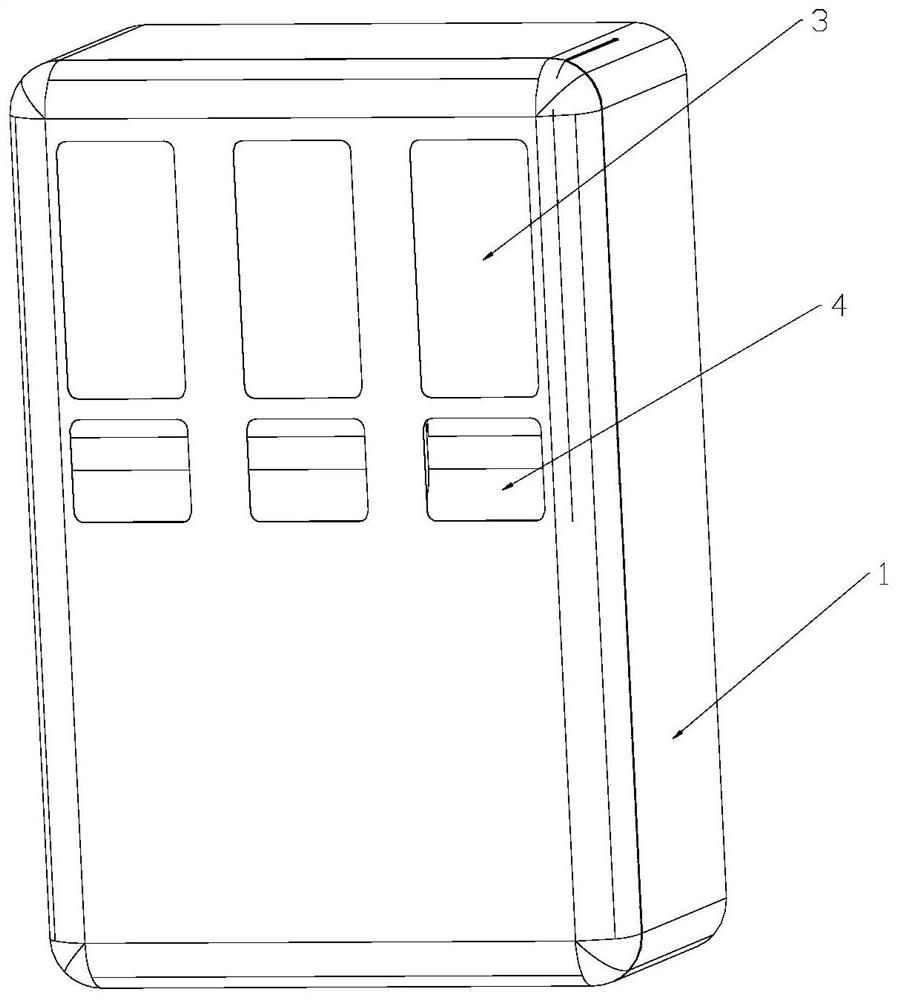

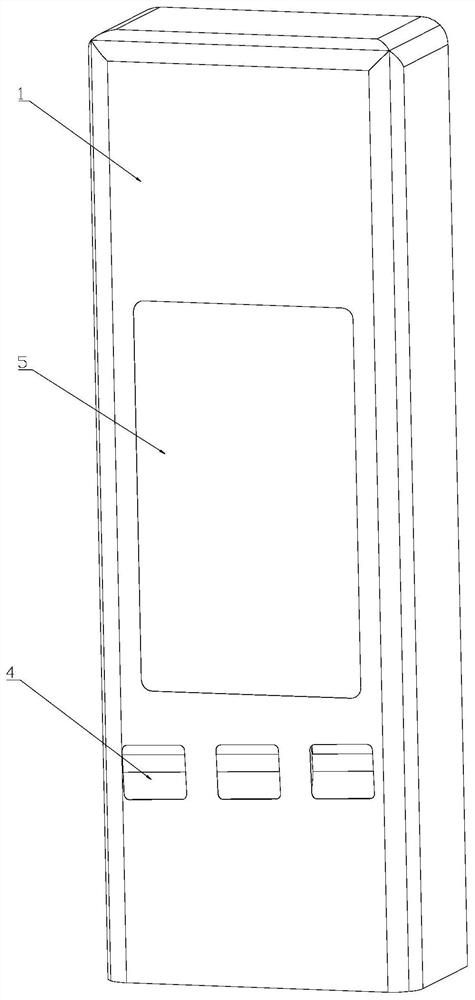

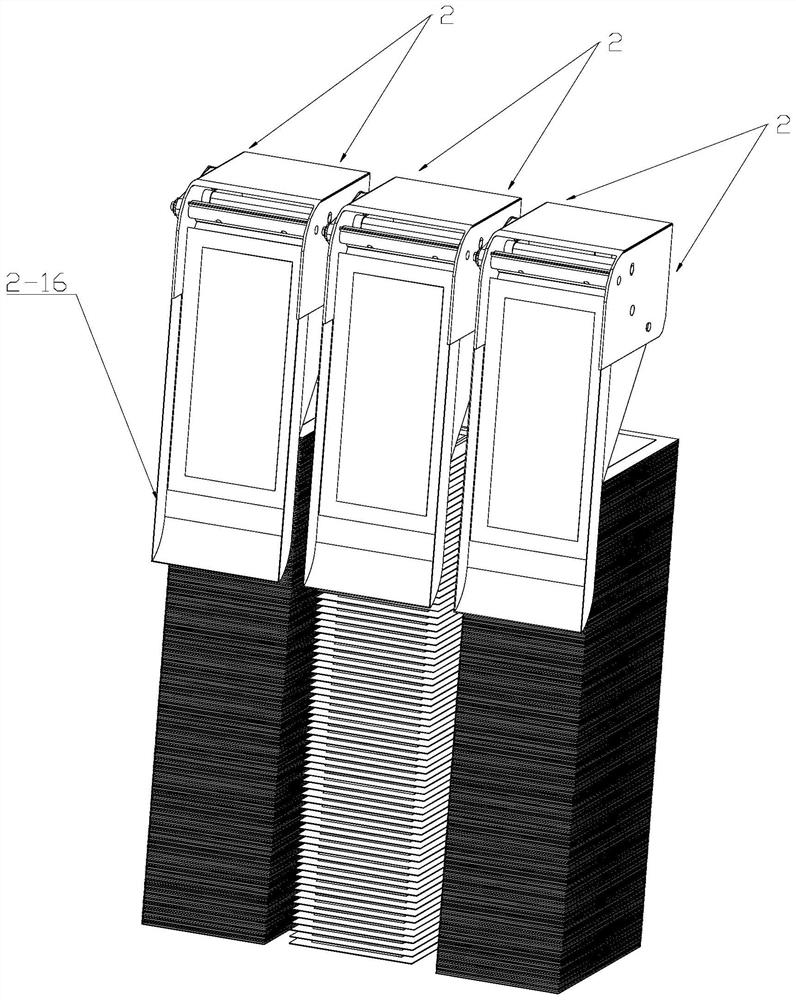

[0043] As shown in the figure, an automatic vending machine for light and thin commodities, the automatic vending machine includes a casing 1 and a transmission and cutting mechanism 2, the transmission and cutting mechanism 2 is located inside the casing 1, and the transmission and cutting mechanism 2 includes Frame 2-1, driving motor 2-2, driving roller 2-3, rotating pressing roller 2-4, cutting assembly 2-5 and tensioning pulley 2-6, described driving roller 2-3, rotating pressing roller 2 -4. Both ends of the cutting assembly 2-5 are rotatably connected to the frame 2-1, the motor shaft of the driving motor 2-2 is provided with a pulley 2-7, and the driving roller 2-3 and The end of the cutting assembly 2-5 is provided with a pulley 2-7, and the driving motor 2-2 and the driving roller 2-3, the cutting assembly 2-5, and the tension pulley 2-6 pass through the pulley 2-7. Connected with the belt 2-8, the side of the frame 2-1 is equipped with a fixed shaft 2-9, the fixed sh...

Embodiment 2

[0050] As shown in the figure, an automatic vending machine for light and thin commodities, the automatic vending machine includes a casing 1 and a transmission and cutting mechanism 2, the transmission and cutting mechanism 2 is located inside the casing 1, and the transmission and cutting mechanism 2 includes Frame 2-1, driving motor 2-2, driving roller 2-3, rotating pressing roller 2-4, cutting assembly 2-5 and tensioning pulley 2-6, described driving roller 2-3, rotating pressing roller 2 -4. Both ends of the cutting assembly 2-5 are rotatably connected to the frame 2-1, the motor shaft of the driving motor 2-2 is provided with a pulley 2-7, and the driving roller 2-3 and The end of the cutting assembly 2-5 is provided with a pulley 2-7, and the driving motor 2-2 and the driving roller 2-3, the cutting assembly 2-5, and the tension pulley 2-6 pass through the pulley 2-7. Connected with the belt 2-8, the side of the frame 2-1 is equipped with a fixed shaft 2-9, the fixed sh...

Embodiment 3

[0057] As shown in the figure, an automatic vending machine for light and thin commodities, the automatic vending machine includes a casing 1 and a transmission and cutting mechanism 2, the transmission and cutting mechanism 2 is located inside the casing 1, and the transmission and cutting mechanism 2 includes Frame 2-1, driving motor 2-2, driving roller 2-3, rotating pressing roller 2-4, cutting assembly 2-5 and tensioning pulley 2-6, described driving roller 2-3, rotating pressing roller 2 -4. Both ends of the cutting assembly 2-5 are rotatably connected to the frame 2-1, the motor shaft of the driving motor 2-2 is provided with a pulley 2-7, and the driving roller 2-3 and The end of the cutting assembly 2-5 is provided with a pulley 2-7, and the driving motor 2-2 and the driving roller 2-3, the cutting assembly 2-5, and the tension pulley 2-6 pass through the pulley 2-7. Connected with the belt 2-8, the side of the frame 2-1 is equipped with a fixed shaft 2-9, the fixed sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com