Orthogonal differential flexible electromagnetic sensor for residual stress detection

An electromagnetic sensor, residual stress technology, applied in the direction of force measurement, force/torque/work measuring instrument, instrument, etc. by measuring the change of magnetic properties of materials caused by applied stress, which can solve the problem of low signal-to-noise ratio and large influence of operating frequency. and other problems, to achieve the effect of convenient production, elimination of the influence of the background magnetic field, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

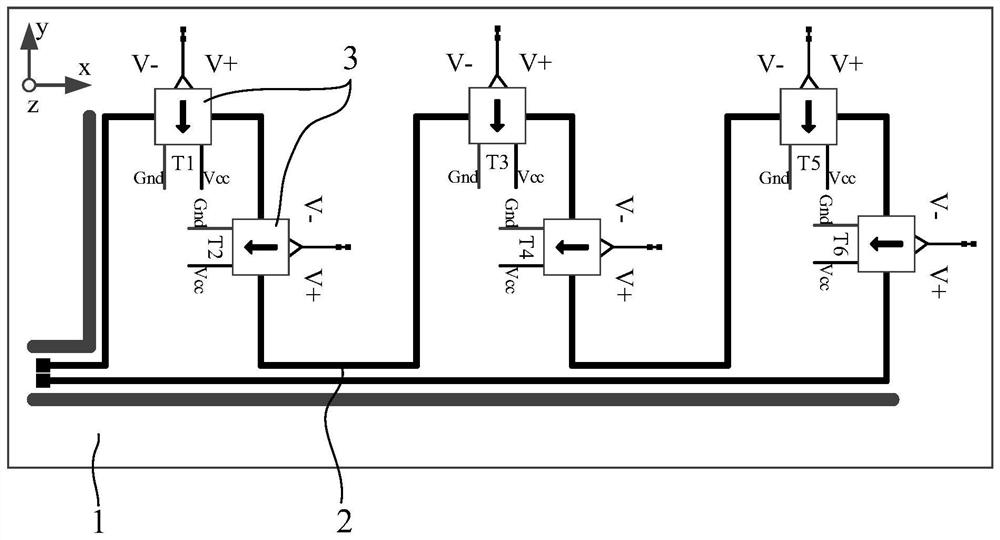

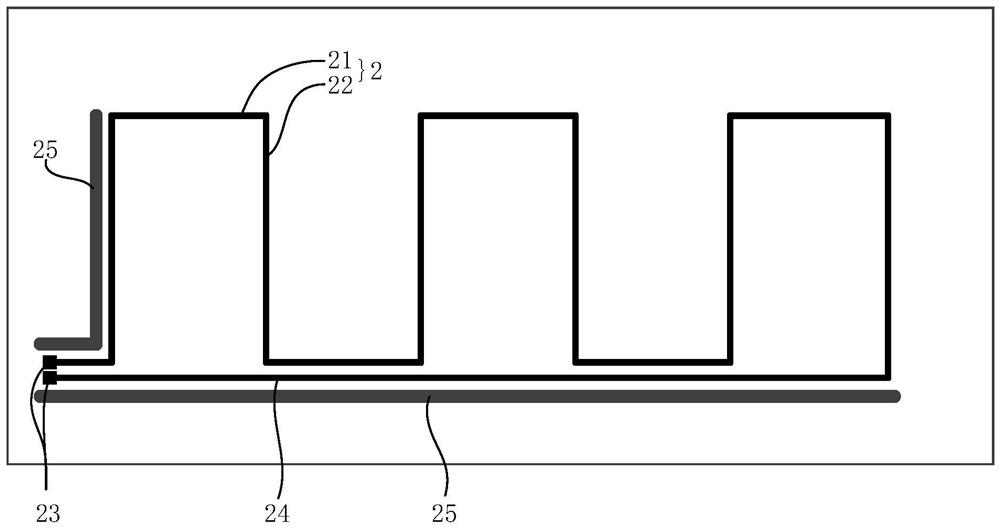

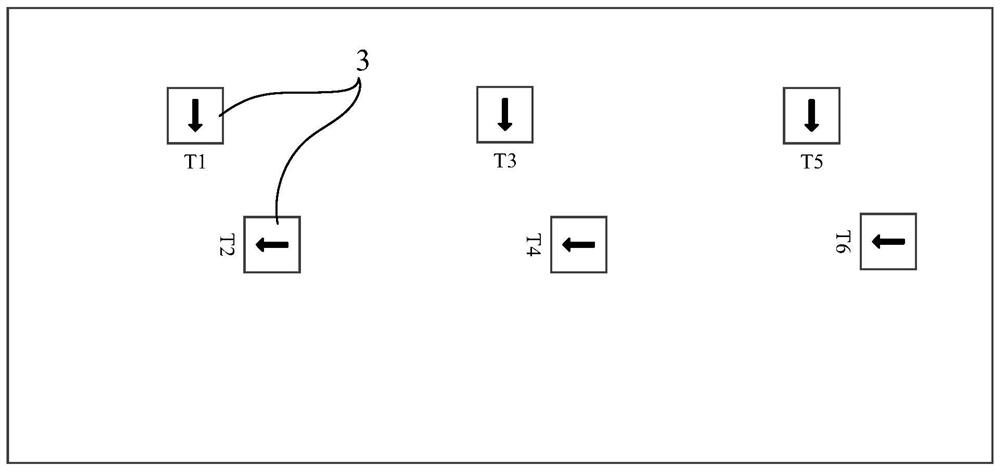

[0028] Such as figure 1 , figure 2 and image 3 As shown, the orthogonal differential flexible electromagnetic sensor used for residual stress detection in this embodiment includes a flexible substrate 1 with a multi-layer structure, and an excitation coil 2 is arranged on the first designated layer of the flexible substrate 1, and the excitation coil 2 includes one or more A square-wave repeating unit, the second designated layer of the flexible substrate 1 is provided with a detection unit corresponding to the repeating unit one by one, and the detection unit includes two TMR elements (tunneling magnetoresistance effect magnetoresistive sensors) 3 placed orthogonally. It should be noted that the repeating unit of the excitation coil 2 has a spatially periodic structure, which may include one repeating unit, or may include multiple repeating units as required. For example, the present example is an example containing 3 repeating units.

[0029] Such as figure 1 , figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com