Horizontal and vertical screen switching structure and liquid crystal touch all-in-one machine applying same

An all-in-one, horizontal and vertical screen technology, applied to supporting machines, mechanical equipment, machines/stands, etc., can solve problems such as inability to switch display modes, inconvenience for users, and inability to rotate the LCD touch all-in-one to switch between horizontal and vertical. The method is simple and stable, and the effect of easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

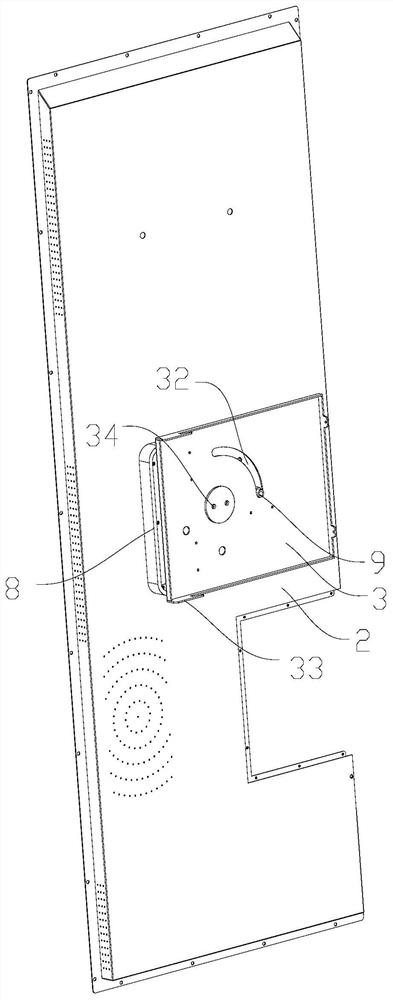

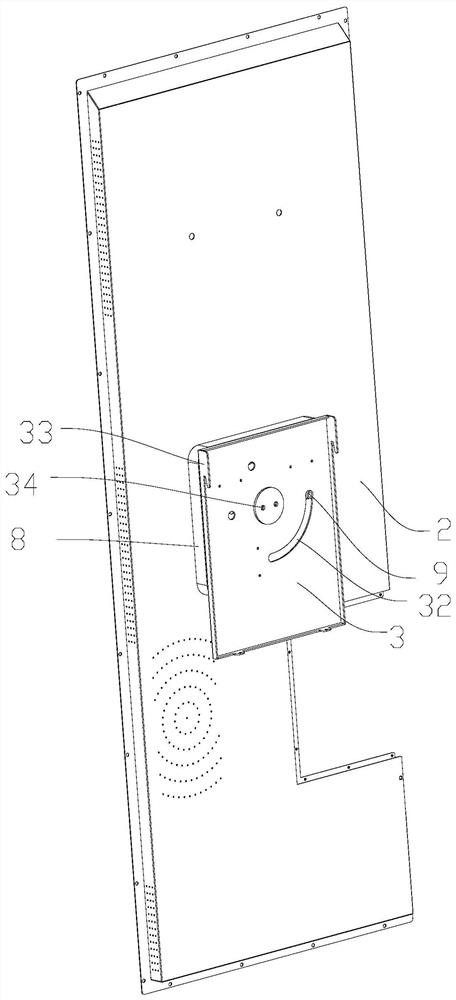

[0036] like Figure 1-4 As shown, the horizontal and vertical screen switching structure includes a rotating part 1 installed on the back cover of the liquid crystal touch all-in-one machine 2, a connecting part 4 inserted into the rotating part 1 and rotatably connected to the rotating part 1, and the connecting part 4 The bracket 3 that is fixedly connected, and the bracket 3 can be hung on a wall, or a frame, or a position that can be hung on a cabinet wall or the like.

[0037] Specifically, the bracket 3 is provided with two hooks 33 for hanging.

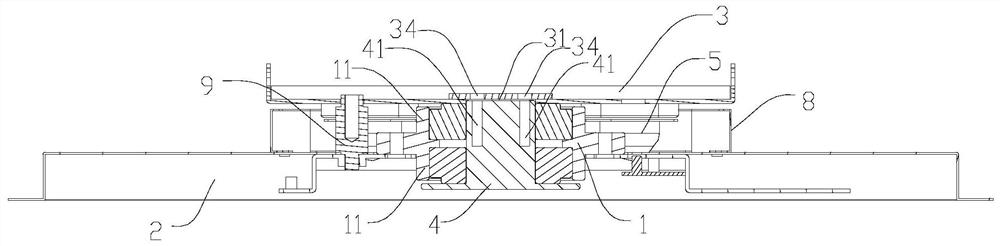

[0038] Wherein, the two ends of the rotating member 1 are provided with protruding rings 11 extending outward, the end of one of the protruding rings 11 is in conflict with the bracket 3, and the other protruding ring is inserted into the liquid crystal touch all-in-one machine 2 , the rotating member 1 interferes with the back cover of the liquid crystal touch all-in-one machine 2, and is screwed and fixed with the back cover...

Embodiment 2

[0060] like Figure 4 As shown, a liquid crystal touch all-in-one machine using the horizontal and vertical screen switching structure of Embodiment 1 includes a plurality of card holes 21 and connection holes 22 provided on the back cover.

[0061] Wherein, the elastic protrusion 51 is engaged in the locking hole 21 in an elastically shrinkable manner.

[0062] Wherein, the connecting piece 4 passes through the connecting hole 22 , is inserted into the installation hole 12 from the liquid crystal touch all-in-one machine 2 , and is screwed and fixed with the bracket 3 .

[0063] Wherein, the rear cover of the liquid crystal touch all-in-one machine 2 is provided with a plurality of second screw holes 23 matched with the first through holes 13, and the first through holes 13 and the second screw holes 23 are passed through by means of screws or screws. The two screw holes 23 are screwed and connected to fix the rotating member 1 on the back cover.

[0064] Wherein, the insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com